Transport and refueling truck for mining area

A technology for fuel trucks and mining areas, applied in the field of fuel trucks used in mining areas, can solve the problems of low chassis power, increased safety hazards, and weak carrying capacity, and achieve the effects of large chassis power, reduced procurement, and strong carrying capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

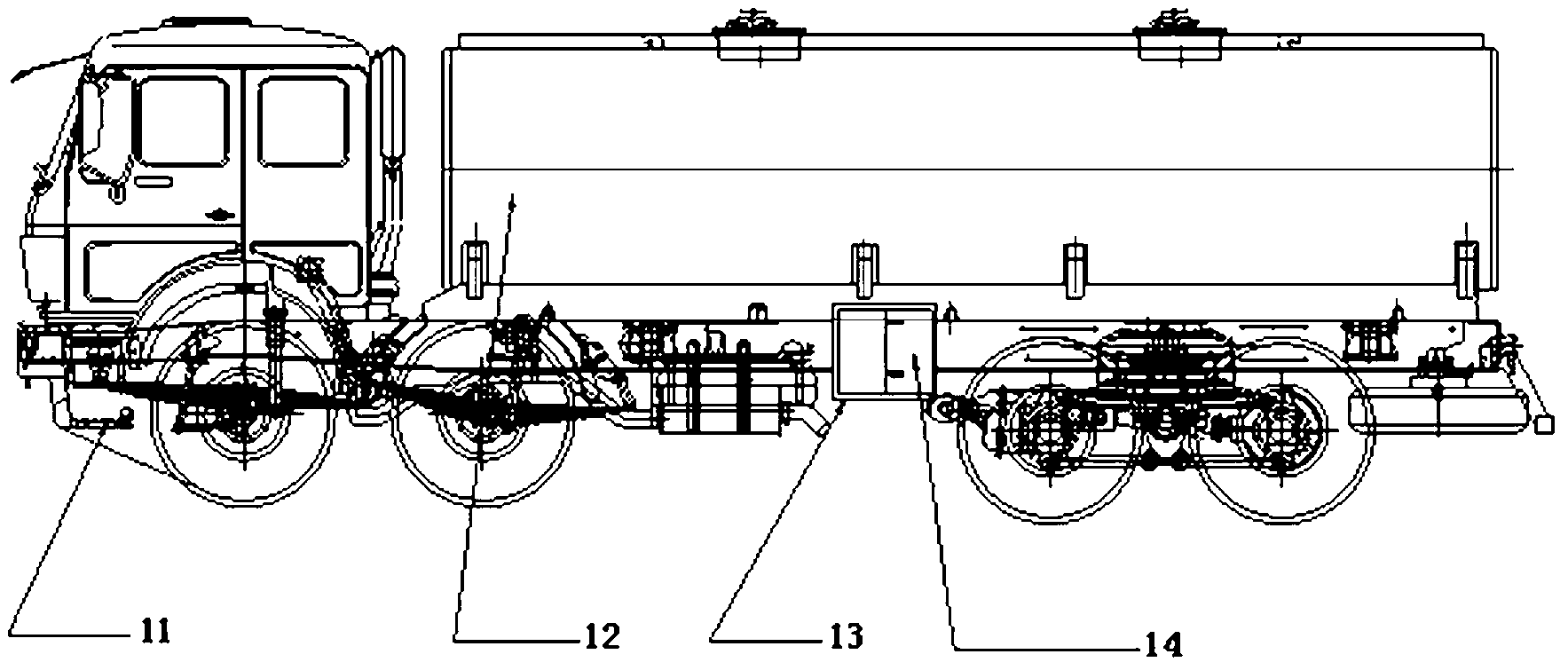

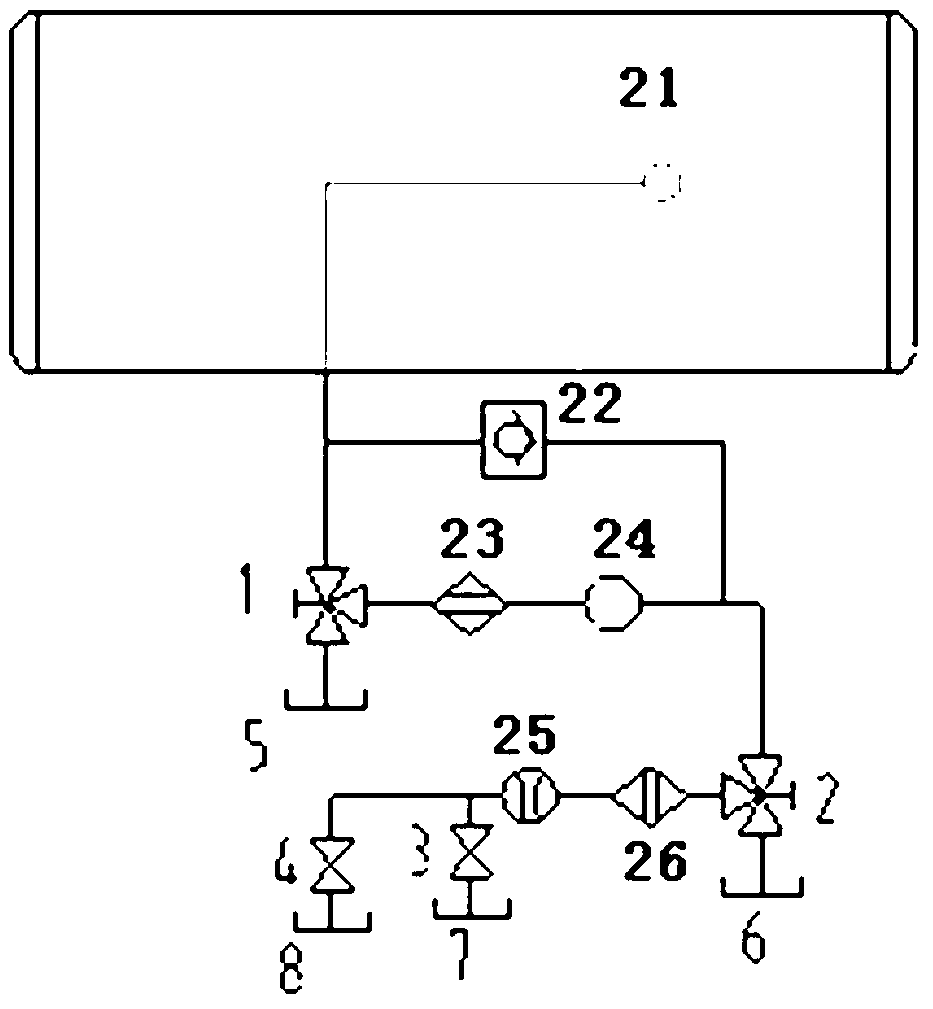

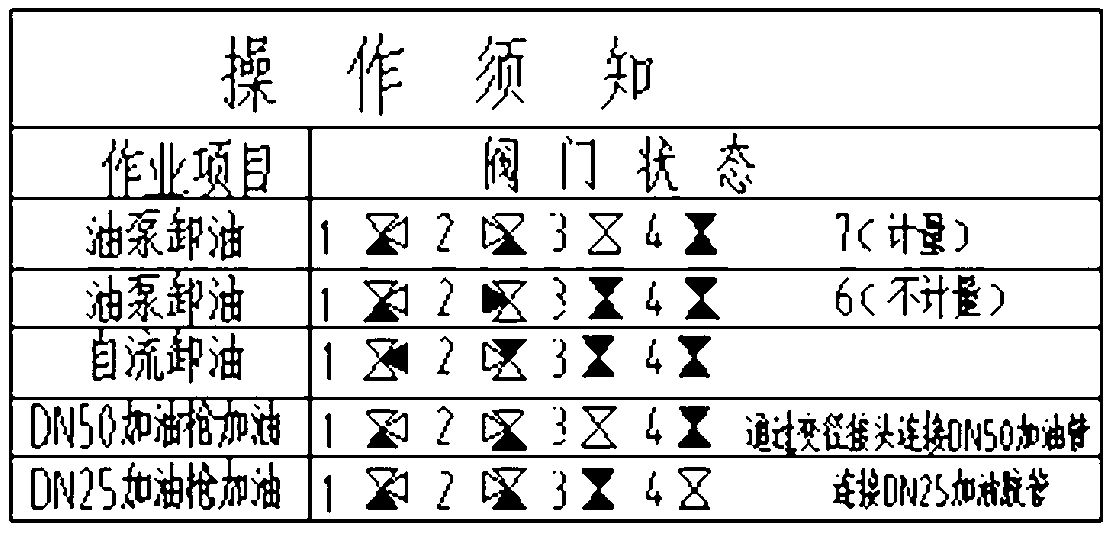

[0026] The present invention relates to a kind of transportation refueling vehicle used in mining area, such as figure 1 As shown, the fuel truck mainly includes: a chassis system 11, an oil tank system 12, a control box 13 and an oil pump pipeline system 14, and the chassis system 11 includes four parts: a transmission system, a driving system, a steering system and a braking system. It is used to support and install the automobile engine and its various components and assemblies. The oil tank system 12 includes a tank body for containing oil. The control box 13 is arranged on the left side of the vehicle driving direction, including system, the operating system is used to operate the chassis system, the oil tank system and the pumping pipeline system, and the pumping pipeline system 14 is arranged in the control box. The pump oil pipeline system of the fuel truck used in the mining area is designed with at least 3 kinds of pipelines and joints of different calibers. The pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com