Scoring saw assembly which can be pivoted on both sides

A technology of sawing machine and scribing groove, which is applied in the direction of circular saws, sawing equipment, sawing machine devices, etc., which can solve the problems of reducing rigidity and unfavorable cutting accuracy, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

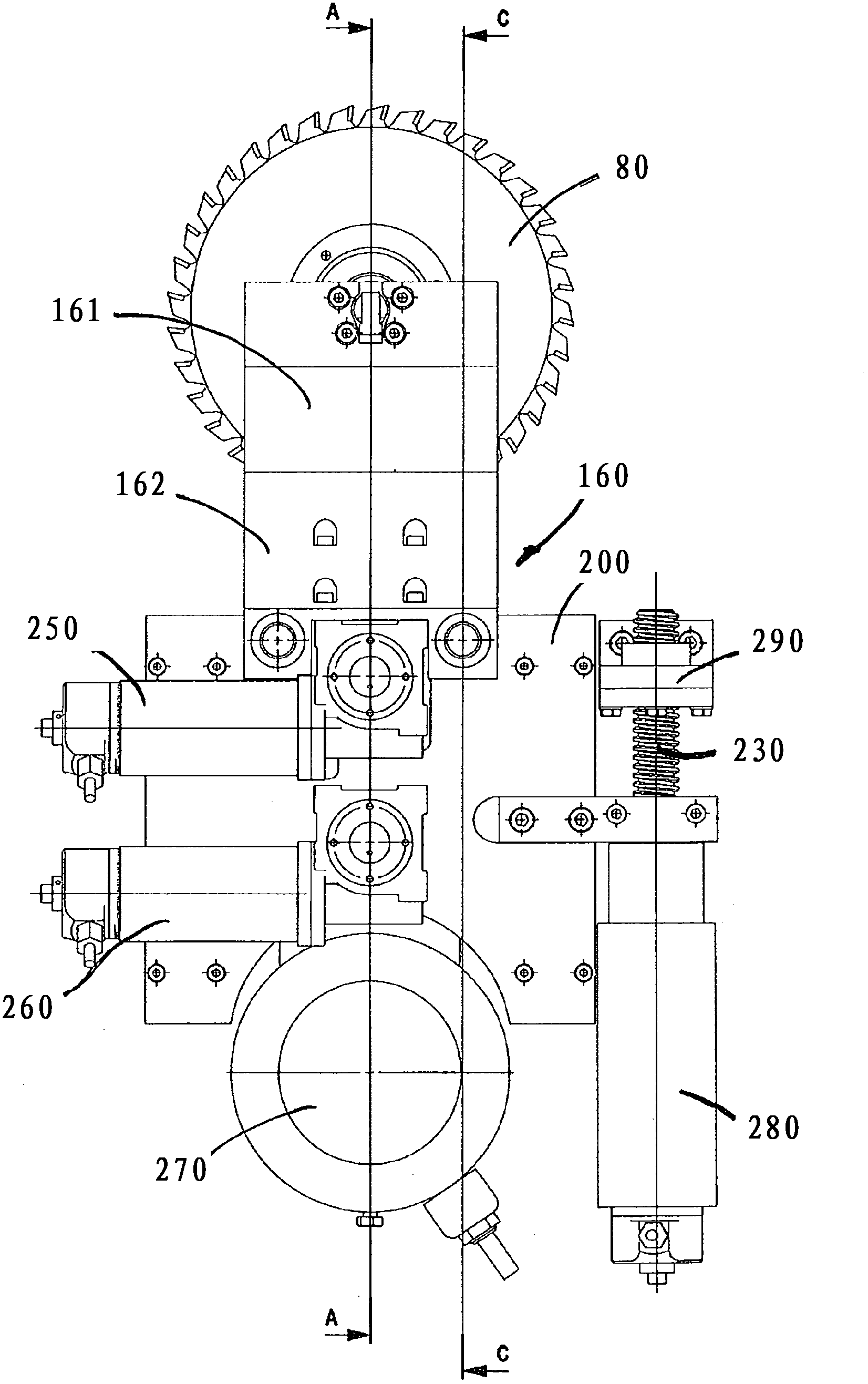

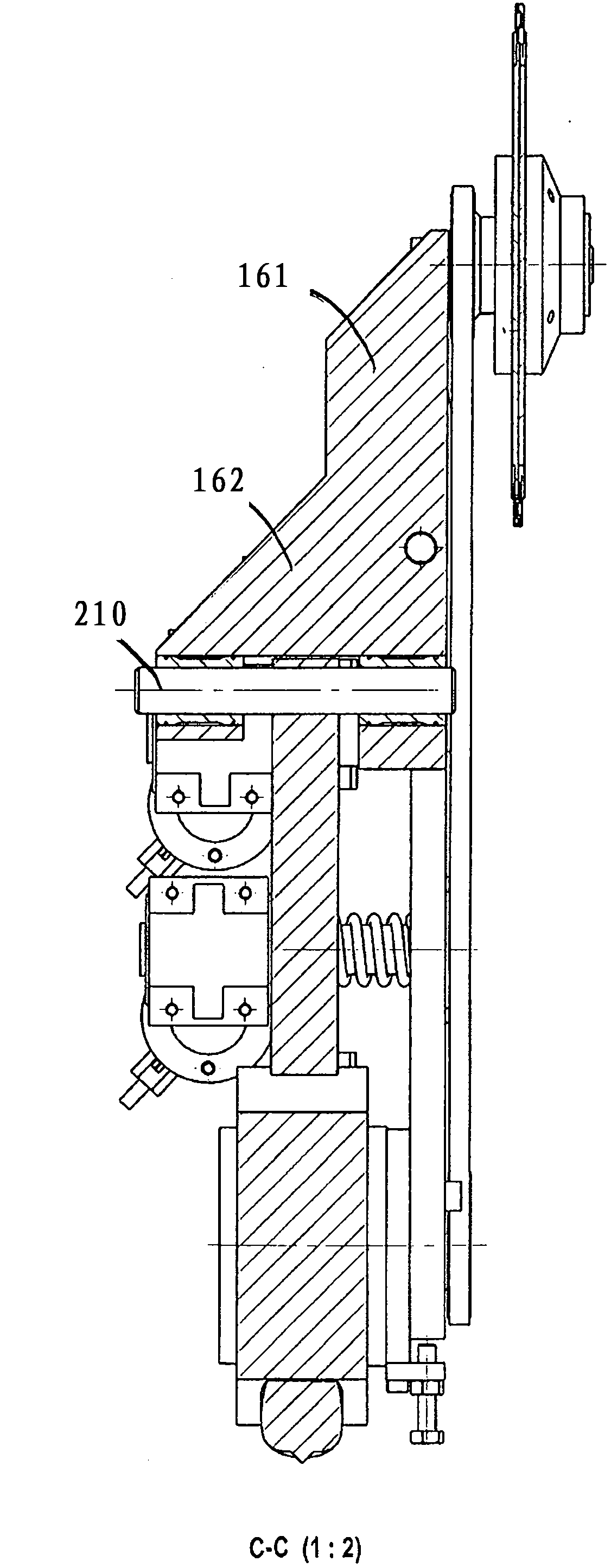

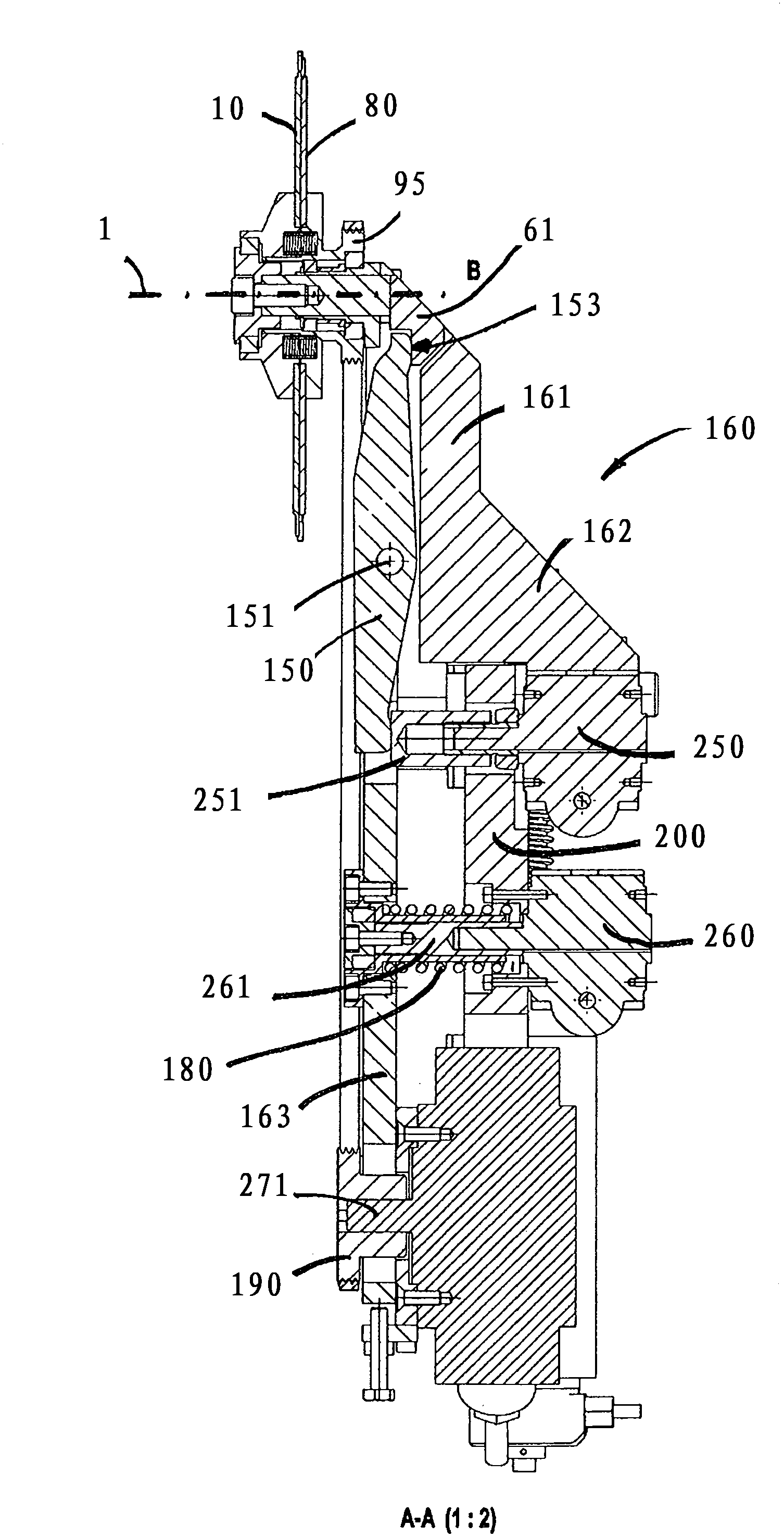

[0036] figure 1 According to the invention, the scribe saw machine includes a scribe saw blade 80 which is turned and rotated by a driving motor 270 . The scoring saw blade 8 is placed on the support 160 and is rotatable.

[0037] The bracket 160 comprises a thin section 161 at the upper end, while it enlarges downwards in a wider section 162 . In the widened section 162 a width actuator 250 is fixed, which is designed as a stepper motor, and it can be seen in the axis of rotation 251 that it extends parallel to the axis of rotation of the scoring saw blade 1 .

[0038] The rotating shaft 251 is mechanically connected to the adjusting rod 150 , and it can deflect toward the adjusting rod shaft 151 and is fixed on the armrest 160 . The adjustment lever shaft 151 is located between the connection point of the adjustment lever to the rotational axis 251 of the width adjustment actuator 250 and the connection point 153 to the adjustment lever on the transfer element 61 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com