Nylon tube feeder and using method thereof

A nylon tube and feeder technology, applied in metal processing and other directions, can solve the problems of low cutting efficiency, affecting the quality of the tube, uneven nylon tube ports, etc., and achieve the effect of precise positioning and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

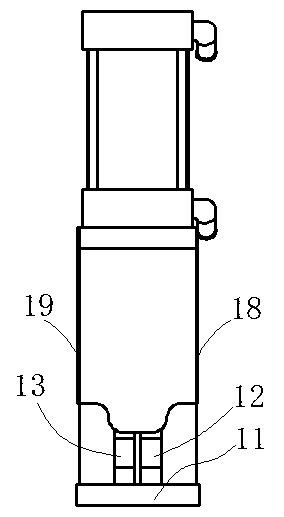

[0031] as attached figure 1 to attach Figure 11 Shown, the present invention comprises following assembly: feeder frame 1, power cylinder 2 and nylon pipe cutter 3, and operation control device, its power cylinder 2 is fixed on the top of feeder frame 1, and nylon pipe cutter 3 is installed on The lower part of the power cylinder 2 provides cutting power for the nylon tube cutter 3 by the power cylinder 2; wherein:

[0032] Bottom feeder frame 1 is provided with a base 11, adopts screw to be fixed side by side with a left fixed block 13 and the right fixed block 12 on this base 11; There is a concave notch for placing the cut nylon tube; the accommodation between the left fixed block 13 and the right fixed block 12 arranged side by side has a knife body 31 for accommodating the nylon tube cutter 3 for vertical cutting movement, ensuring that the nylon tube The matching clearance of the cutter 3 in a good motion state; the two sides of the base 11 are fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com