Exhaust device used for casting die

A technology for exhaust devices and die-casting molds, which is applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve problems such as interruption of die-casting operations, temperature drop, metal residues, etc., to achieve simple and easy maintenance and management, reduce frictional resistance, Effect of suppressing thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

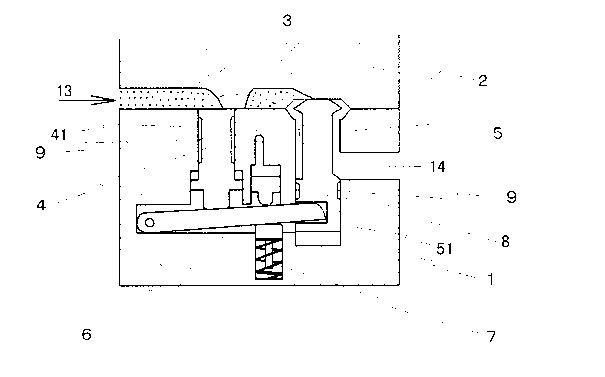

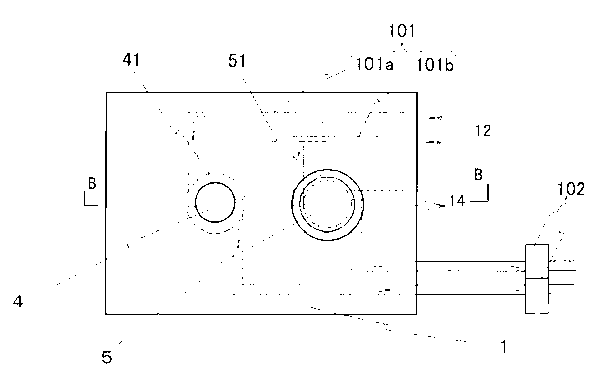

[0044] Embodiment 1: The exhaust device for a die-casting mold provided in this preferred embodiment is as attached figure 1 , attached figure 2 shown, with figure 1 Provided that the fixed module 1 is equipped with the situation of the gas delivery device 10, the appended figure 2 is attached figure 1 A-A sectional view of A-A shows the cross-section of the exhaust device. At the same time attached figure 1 It is the top view of the moving module 2 of the exhaust device after it has been folded off. The symbol 1 shows the fixed module for die-casting, the symbol 2 shows the moving module, and the symbol 3 shows the space between the fixed module 1 and the moving module 2. An exhaust passage formed and communicated with the die-casting mold cavity. Marked 4 is a pressure-receiving plunger located at the intake side 13 of the exhaust passage 3, and the pressure-receiving plunger 4 is arranged on the fixed module 1 and can move up and down.

[0045] Marked 5 is a blo...

Embodiment 2

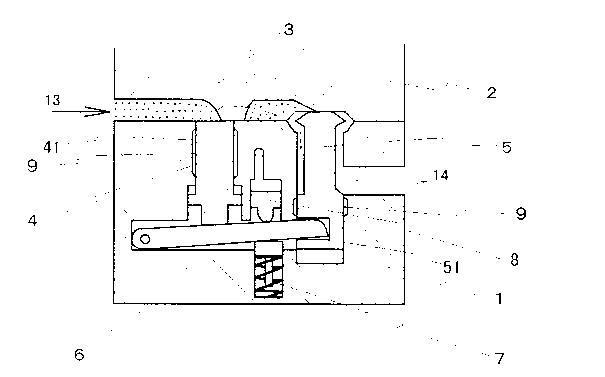

[0047] Embodiment 2: A kind of exhaust device for die-casting mold that this preferred embodiment provides is as attached image 3 , attached Figure 4 As shown, the difference between this preferred embodiment and the first embodiment lies in the formation of the air stagnation portion 9. Obviously, the air stagnation portion 9 may not be formed by cutting the outer circumferences of the pressurized plunger 4 and the lock valve 5 respectively. , but formed by cutting one side of the fixed module 1. Of course, it is also possible to cut the fixed module 1 on one side to form the air stagnation portion 9, and the other side still cuts the outer circumference of the pressure plunger 4 or the lock valve 5 to form the air stagnation portion 9. In this preferred embodiment, the appended Figure 4 The situation shown is that the air retention part 9 on the plunger sliding part 41 on the pressure receiving plunger 4 is formed on the side of the cutting module 1, and the air retentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com