Fully-hydraulic counter-blow hammer

A counter-hammer, fully hydraulic technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, power hammers, etc., can solve the problems of complex structure and linkage structure prone to failure, and achieve simple structure, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

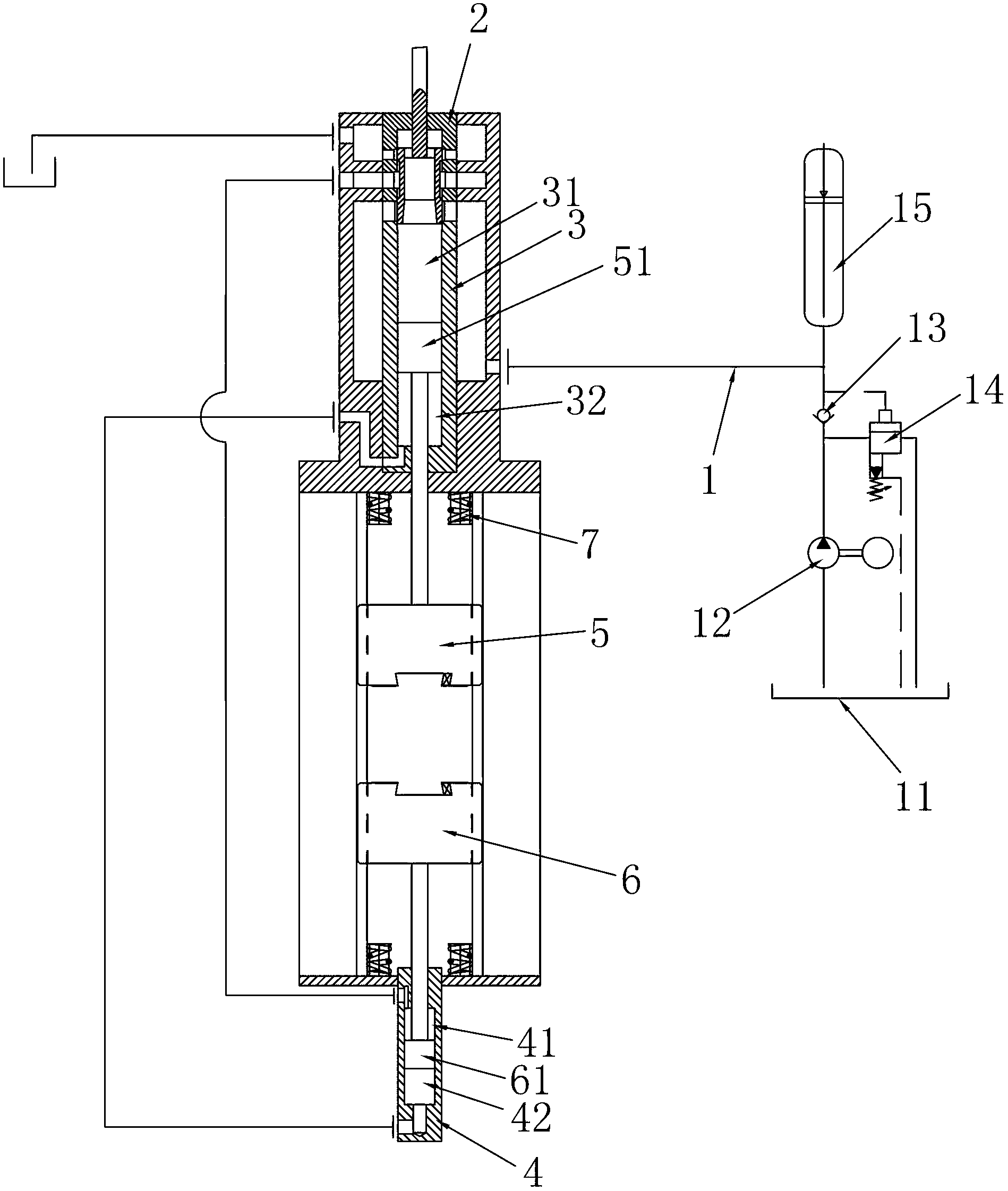

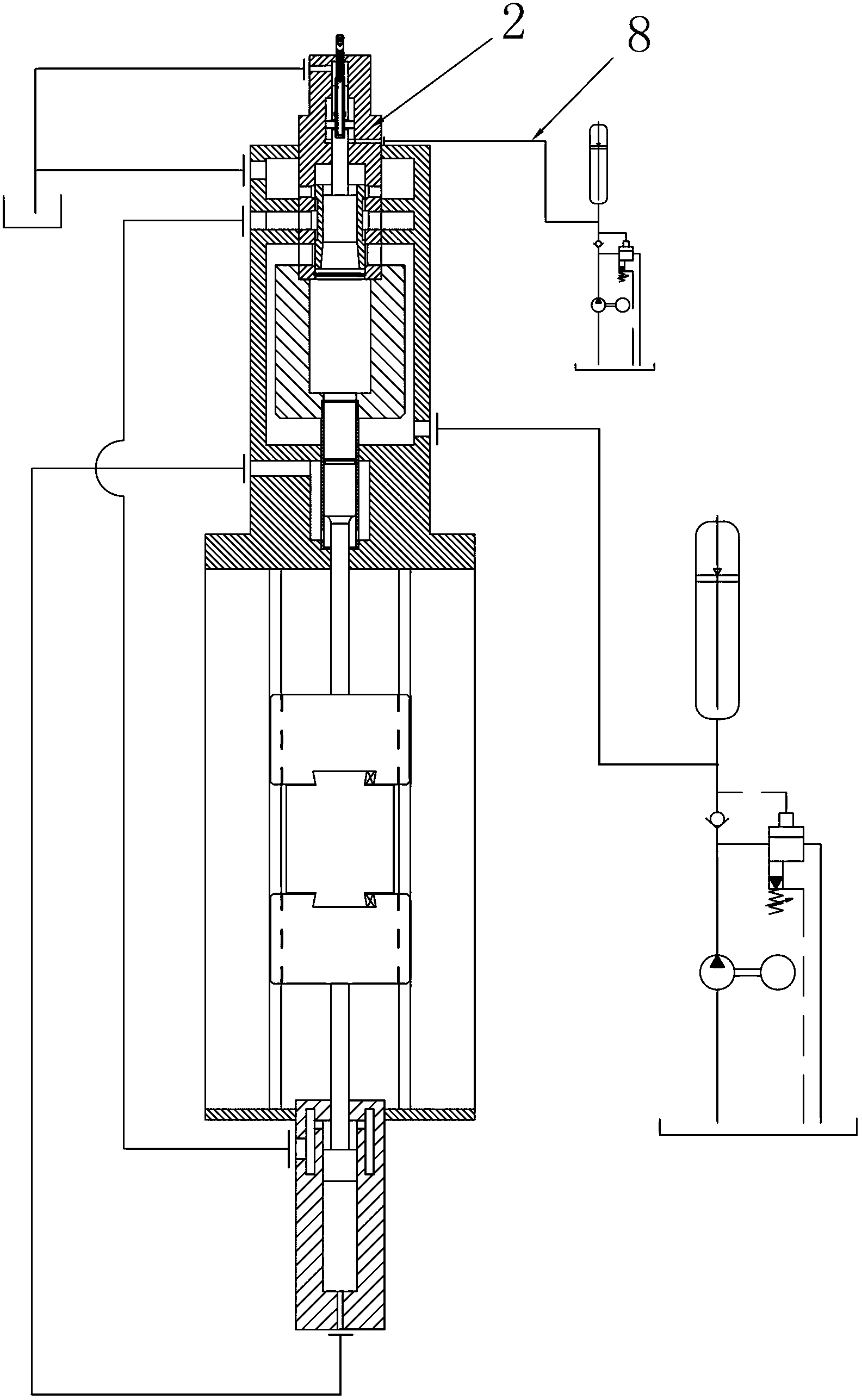

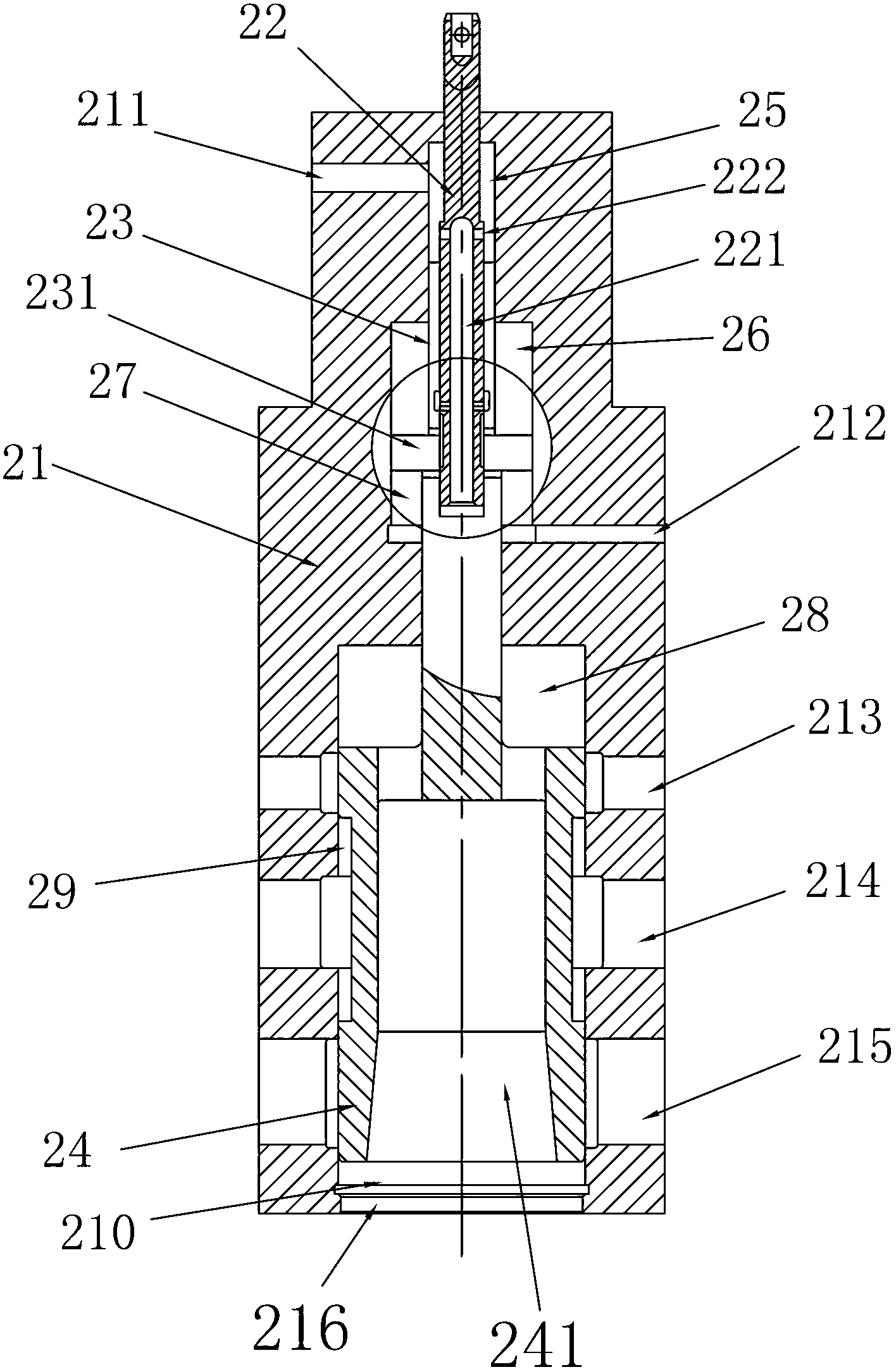

[0027] like figure 1As shown in the first embodiment of the full hydraulic counter hammer of the present invention, the upper hammer head 5 and the lower hammer head 6 are arranged vertically opposite each other, the upper hammer head 5 is connected to the upper hammer rod piston 51, and the lower hammer head 6 is connected to the lower hammer Rod piston 61, the upper hammer rod piston 51 is placed in the upper drive cylinder 3 and the upper drive cylinder 3 is divided into an upper drive upper cavity 31 and an upper drive lower cavity 32, and the lower hammer rod piston 61 is placed in the lower drive cylinder 4 and the lower drive cylinder 3 is divided into an upper drive upper cavity 31 and an upper drive lower cavity 32. The driving cylinder 4 is divided into a lower driving upper chamber 41 and a lower driving lower chamber 42. The upper driving lower chamber 32 is sealed and communicated with the lower driving lower chamber 42 to form a closed cavity, which is filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com