Lens calibration system and method thereof

A technology for calibrating systems and lenses, applied in installation, optics, focusing devices, etc., can solve the problems of long focusing time, high production costs, and high labor costs, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

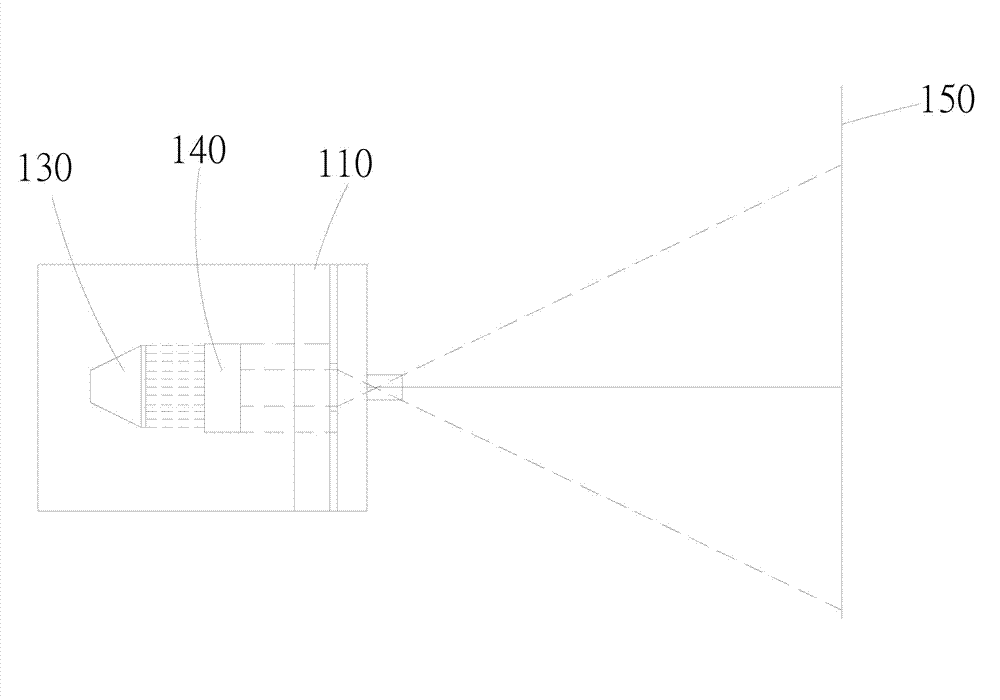

[0054] Please also refer to figure 2 and image 3 ,in figure 2 It is a block diagram of an embodiment of the lens calibration system of the present invention. image 3 It is a schematic diagram of an embodiment of the lens calibration system of the present invention. figure 2 Among them, the lens calibration system 200 includes a target pattern display 210 , a calibration platform 220 , an image test module 230 and a motor module 240 . The target pattern display 210 is used to display a target pattern 211 . The calibration platform 220 is used to place a lens 221 to be calibrated, wherein the calibration platform 220 further includes a calibration mechanism 222 . Wherein, the calibration mechanism 222 is shown as being mechanically connected with the lens 221 to be calibrated. The image testing module 230 includes an image capturing unit 231 and a computing module 232 . In consideration of optical factors, the calibration platform 220 is arranged parallel to the targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com