Resistance type electric heating hot water boiler

A hot water boiler and electric heating technology, applied in the field of boilers, can solve problems such as low thermal efficiency of boilers, and achieve the effects of high thermal efficiency, improving thermal efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

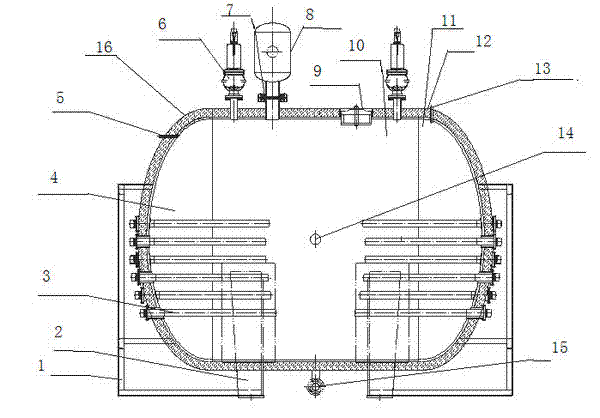

[0020] The boiler shell is welded by the drum 10, the front head 4, and the rear head 11. The gas collecting tank 8 and the water outlet valve seat 7 are connected by flanges. The electric heating tube protection cover 1 and the boiler support 2 are welded on the drum 10. Externally, the electric heater 3 is connected to the electric heating pipe interface with bolts, the safety valve is fixed on the safety valve pipe seat with bolts, the pressure gauge interface 5, the electric heating pipe interface, the safety valve seat 6, the outlet valve seat 7, The manhole 9, the thermometer interface 13, the return valve seat 14, and the blowdown valve seat 15 are all welded to the drum 10 and communicated, and there is a boiler insulation 12 outside the boiler drum.

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com