Engine fan

An engine and fan technology, which can be applied to machines/engines, liquid fuel engines, mechanical equipment, etc., and can solve the problems of consuming engine power and increasing the weight of fans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

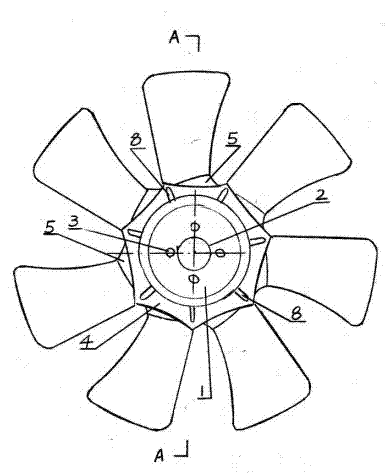

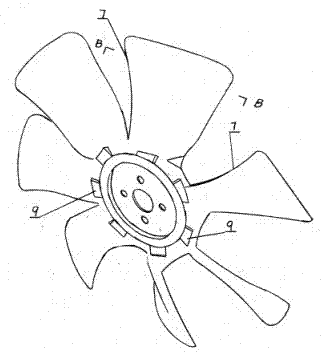

[0011] Such as figure 1 As shown, the fan includes a disc 1 in the center, with a central hole 2, and a group of small holes 3 evenly distributed around the hole. Edges are formed on the periphery, except that the edge wraps a part of the disc 1 to form a convex edge, and extends outward to form a plastic ring 4 with a width. The blades are unevenly distributed on the periphery of the plastic ring. Seven blades are distributed in this embodiment. The above-mentioned uneven distribution means that the included angles between each adjacent two blades are different, forming unequal fan gaps. According to experiments, it can reduce the vibration of the fan. The uneven distribution of this embodiment is manifested in the scale The angle is between 43°-55°.

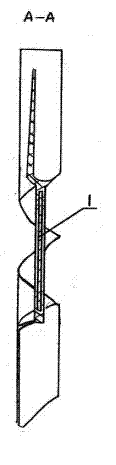

[0012] The width of each blade on the edge of the plastic ring forms the root of the fan blade according to the width obtained by graduation. The curve of the root of the fan blade is twisted at an angle along the plane of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com