Hole sealing and drilling method for downhole gas extraction in coal mine

A technology of gas drainage and drainage drilling, which is applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., can solve the problems of waste of resources, high utilization cost, and low concentration of gas drainage, and achieve Good sealing effect, low sealing cost and high sealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0020] The underground coal mine gas drainage drilling hole sealing method of the present invention comprises the following steps:

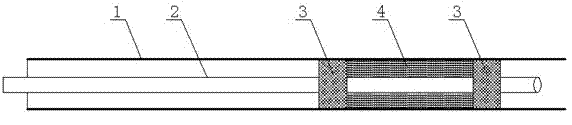

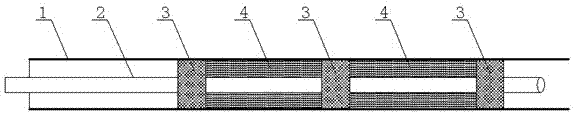

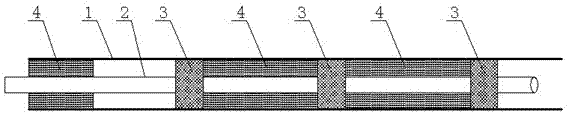

[0021] 1) Insert the sealing baffle bag Ⅰ with baffle foam material, the sealing filling bag Ⅰ with filling foam material and the sealing baffle bag Ⅱ with baffle foam material into the drainage drill in sequence. from the inside of hole 1 to the sealing depth position; figure 1 As shown, the baffle foam material 3 with a short foaming and curing time is used as a "baffle" after foam molding and curing, and the filled foam material 4 is then expanded and extruded in the limited space between the two "baffles". Pressure filling, the baffle foam material and filling foam material will burst the bag during the foaming process;

[0022] 2) After the baffle foam material and filling foam material are foamed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com