Construction method of airship hauling pilot rope technology

A construction method and technology of pilot ropes, applied to bridge parts, erection/assembly of bridges, bridges, etc., can solve problems such as high safety risks, closed waterways, high cost, etc., and achieve the goal of rich social resources, small site requirements, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

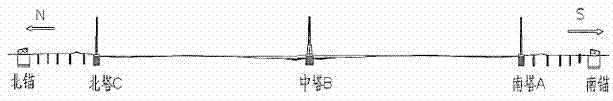

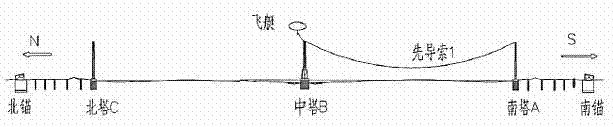

[0030] Taking three bridge towers as an example, the two bridge towers are respectively bridge tower A, bridge tower B and bridge tower C.

[0031] The top of bridge tower A is equipped with hoists and cable racks wound with lightweight fiber ropes, the tops of bridge towers B and C are equipped with hoists and three-phase limit guide wheels, and the bottom anchorages of bridge towers A and C are respectively equipped with hoists. Each pylon is staffed with construction crews carrying walkie-talkies.

[0032] The light fiber rope is composed of 2mm Dyneema rope, 3mm Dyneema rope and 13mm Dyneema rope connected in sequence. The rope head is 2mm Dyneema rope, and the rope tail is 13mm Dyneema rope. The rope tail and the steel wire rope transition The rope and the tow rope are fixedly connected.

[0033] Each section of Dyneema rope is not less than the sum of the distances between towers A and B and between towers B and C.

[0034] Light airships are used, and the parameters o...

Embodiment 2

[0059] The equipment and construction process of this embodiment are basically the same as those of Embodiment 1, except for the single-span construction with only two bridge towers A and B.

[0060] The single-span construction process can be carried out in the following 5 steps:

[0061] Step 1, measure the wind direction and wind speed; use the anemometer and wind vane on the top of the bridge tower to determine the flight of the airship according to the measured wind speed;

[0062] Step 2, inserting flags; inserting flags at the airship take-off point, bridge tower A, bridge tower B and landing point respectively to clarify the flight path of the airship;

[0063] Step 3, pilot cable suspension; the airship operator controls the airship to take off from the take-off point. The rope head of the light fiber rope is fixedly connected with the tractor, that is, the 2mm Dyneema rope is fixedly connected with the tractor; the airship operator controls the airship to retract th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com