Wire aligning method and device used in metal wire melting processing

A technology of metal wire and wire materials, applied in metal processing equipment, optical devices, auxiliary devices, etc., can solve the problems of interruption of processing process, damage of wire feeding system, formation of defects, etc., and achieve a stable and uniform melting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

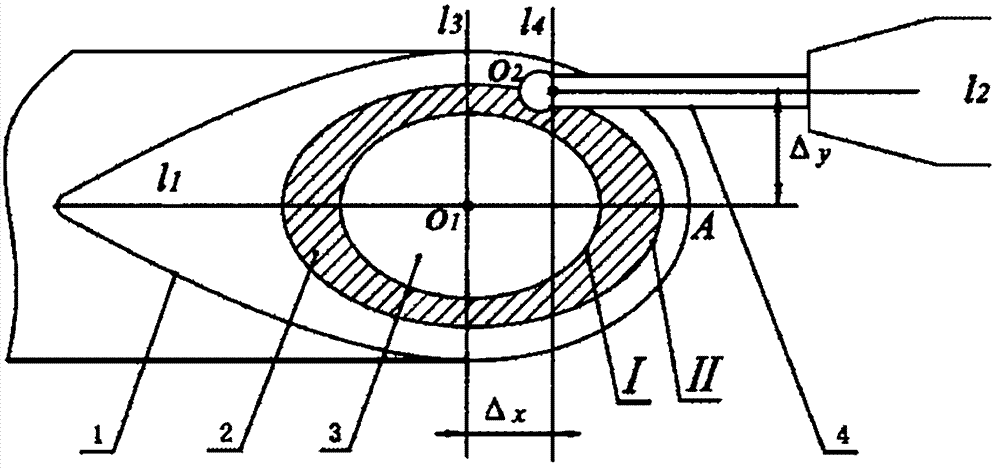

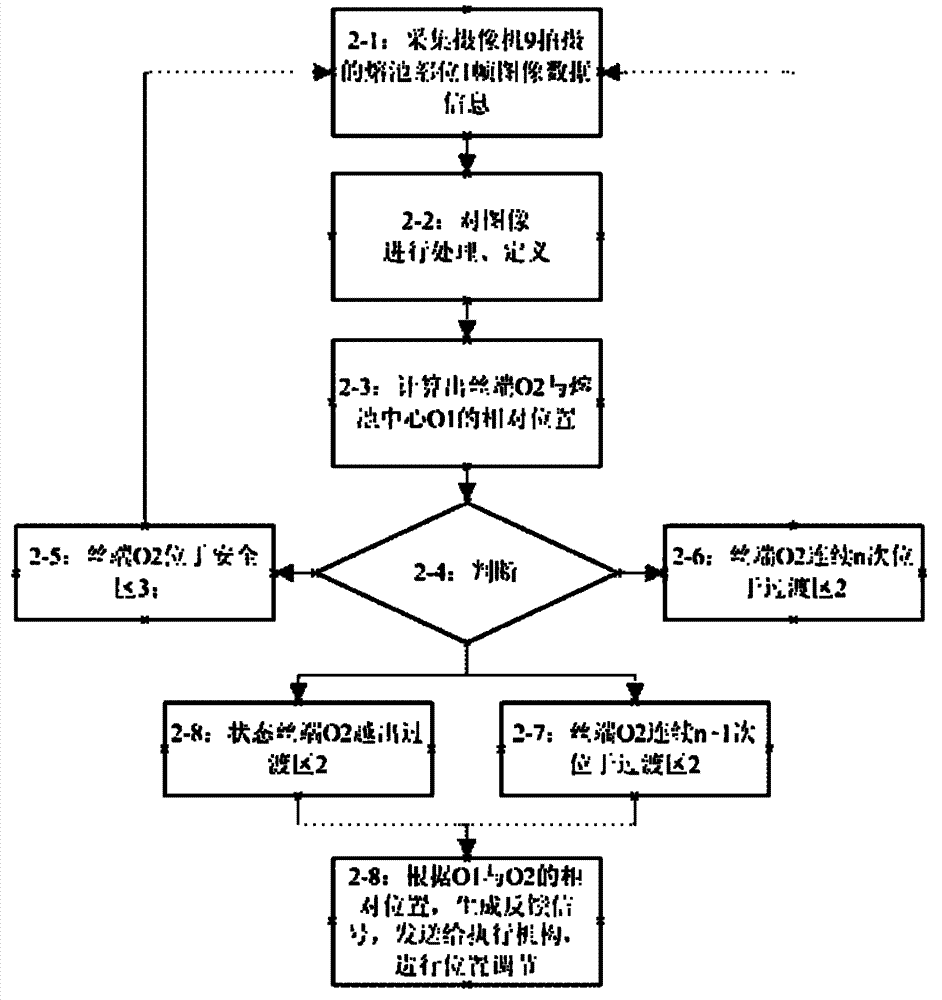

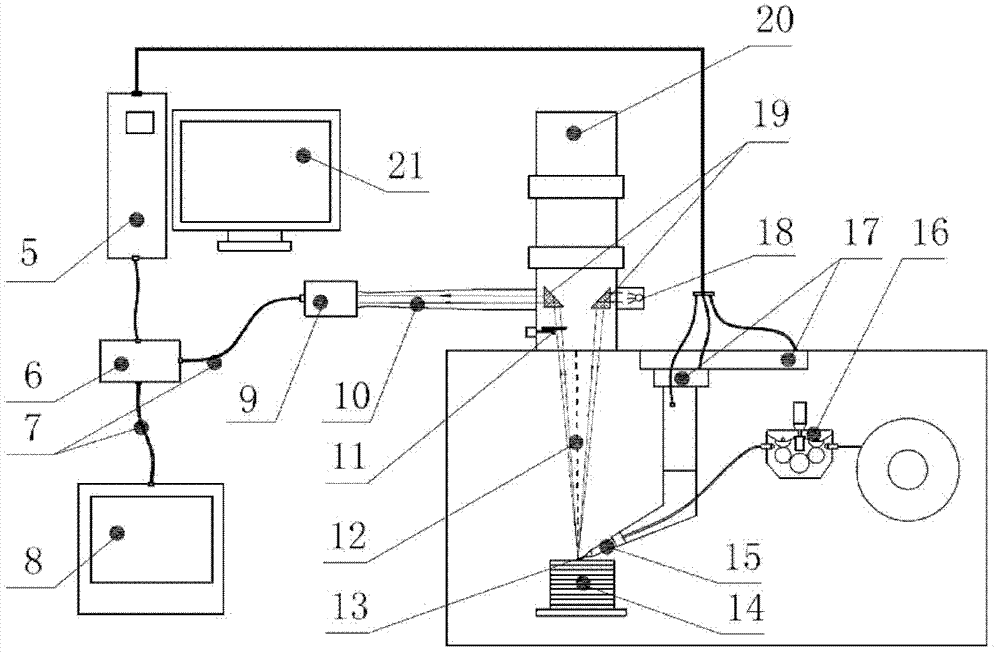

[0037] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0038] The embodiment of the technical solution of the present invention is taking electron beam wire filling processing as an example, refer to the attached image 3As shown, the implementation device of the technical solution of the present invention includes an electron gun 20, a camera 9, a computer 5 and an adjustment actuator 17, etc., the camera 9 is installed on the optical viewing mirror 10, and the camera 9 converts the collected optical information into digital information, and passes through The data line 7 enters the video distributor 6, and the video distributor 6 divides the video signal into two paths, and one path is output to the monitor 8 for real-time observation by operators; There is graphics processing software, which can solve the collected video images.

[0039] The adjustment actuator 17 is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com