Leakage-proof device for pressure water pipe lead-out line interface

A technology of pressure water pipes and anti-leakage devices, applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve the problems of easily damaged power lines of water pumps, poor durability, low sealing efficiency, etc., to facilitate production and installation and Overhaul and disassembly, avoid secondary pollution, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

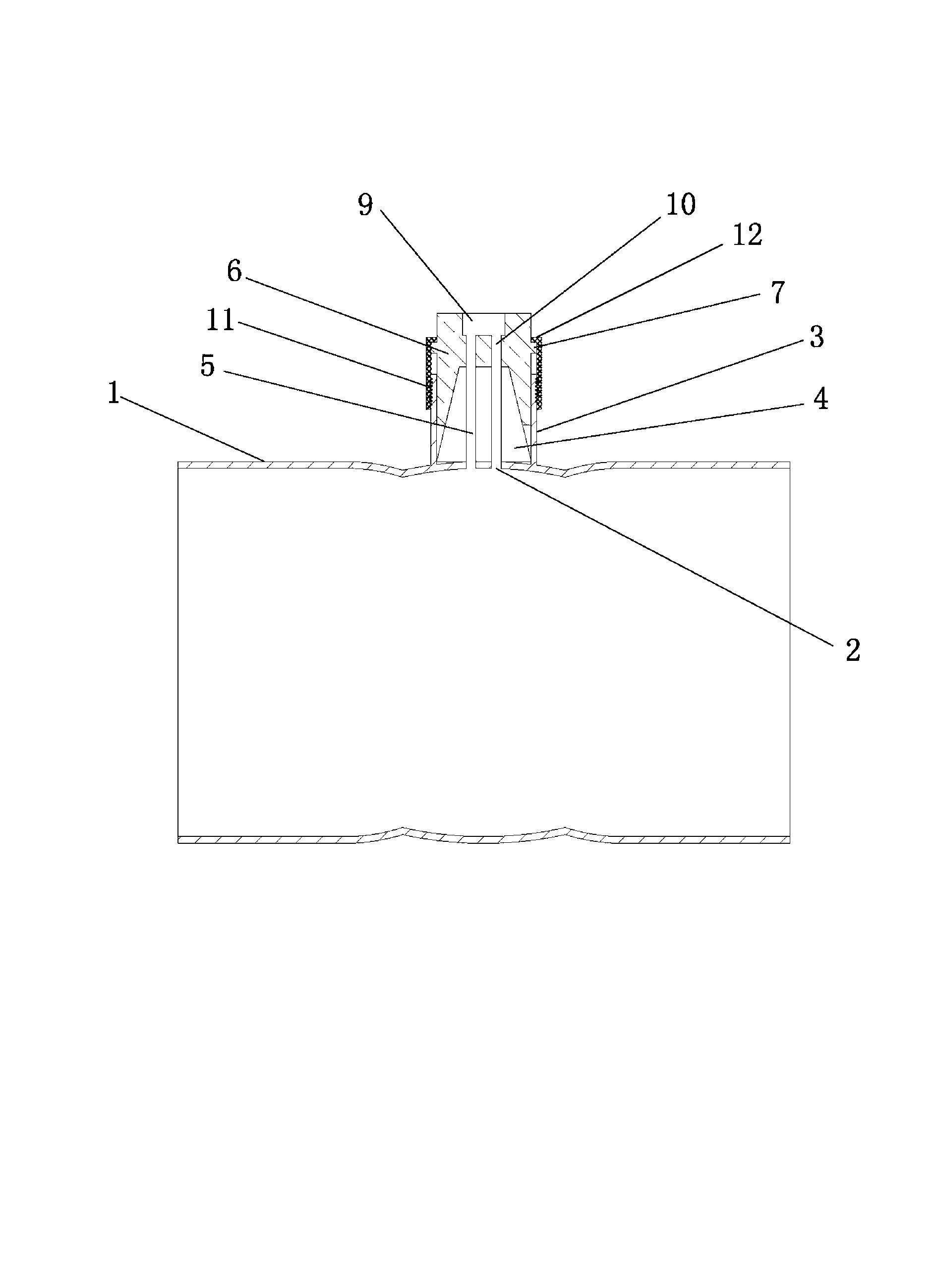

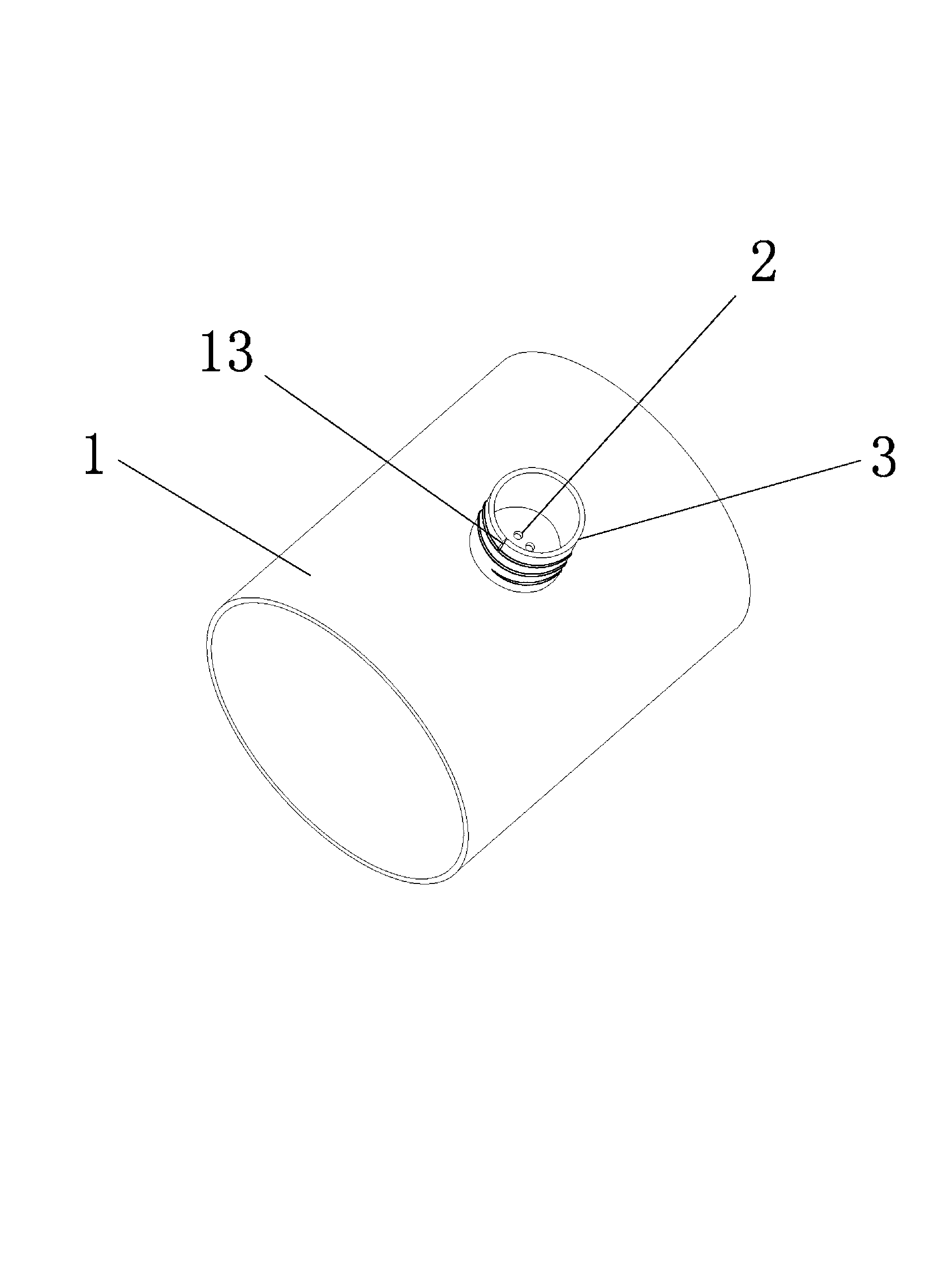

[0043] A leak-proof device for the outlet line interface of a pressure water pipe, comprising a cylindrical hollow sleeve 3 , a rubber seal 4 , a threading pipe core 6 and a stressed nut 11 . The hollow sleeve 3 is welded to the lead-out interface of the submersible pump power line of the pressure water pipe 1, the rubber seal 4 is pressed into the hollow sleeve 3 through the threading pipe core 6, and the threading pipe core 6 is fixed on the hollow sleeve through the stressed nut 11 3, the force nut 11 and the hollow sleeve 3 are connected by threads.

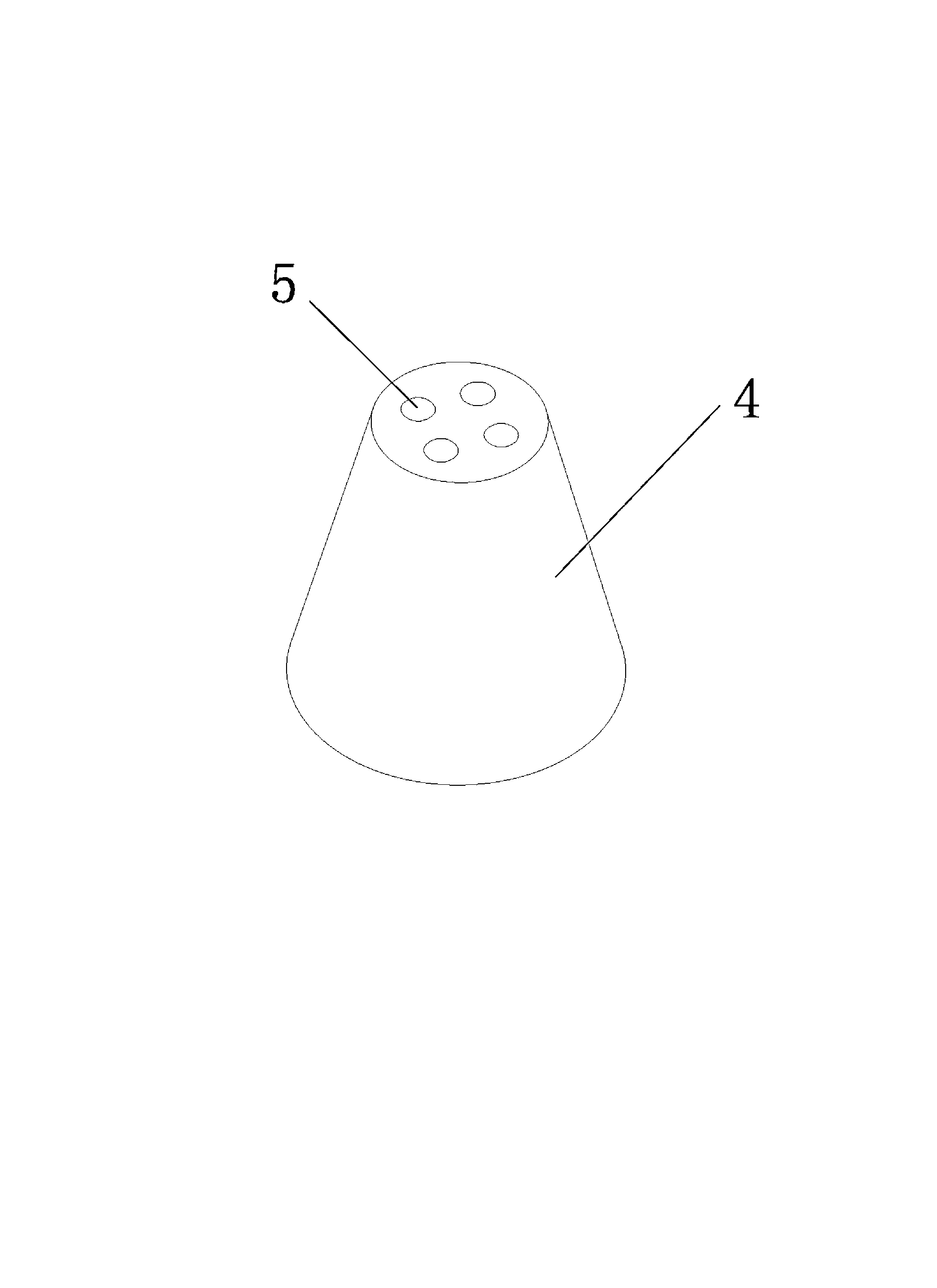

[0044] The pressure water pipe 1 and the hollow sleeve 3 are welded with a pressure water pipe threading hole 2, and the rubber seal 4 is provided with a seal that matches the pressure water pipe threading hole 2 for the power line of the submersible pump to be drawn out from the pressure water pipe 1. The threading hole 5 and the threading pipe core 6 are provided with a threading pipe core outlet hole 10 matched with the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com