Stirring reaction device for synthesizing super absorbent resin

A technology of superabsorbent resin and stirring reaction, which is applied in the direction of chemical/physical/physical chemical fixed reactors, etc., can solve the problems that affect the economic benefits of enterprises, hinder the production efficiency, reduce the yield of finished products, etc., and reduce the adhesion of materials to paddles Leaf phenomenon, high yield, uniform flow field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

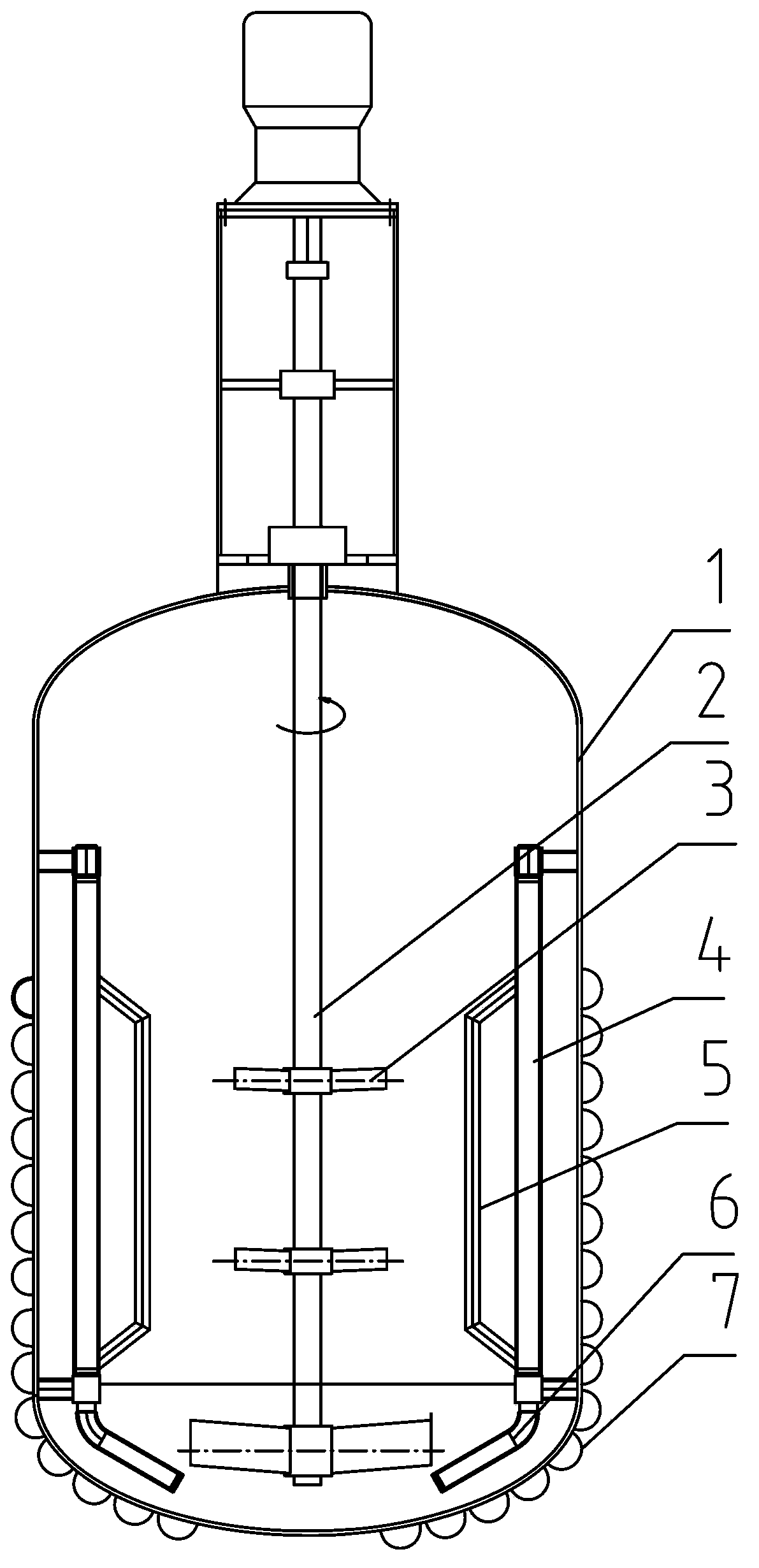

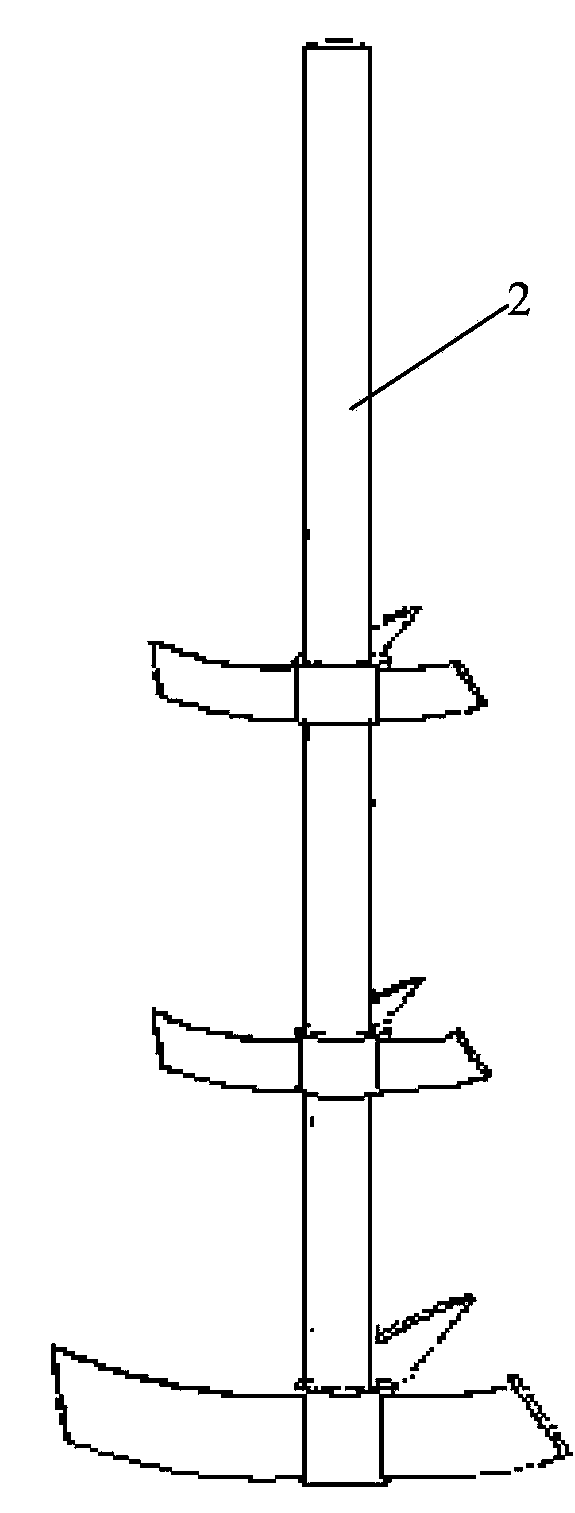

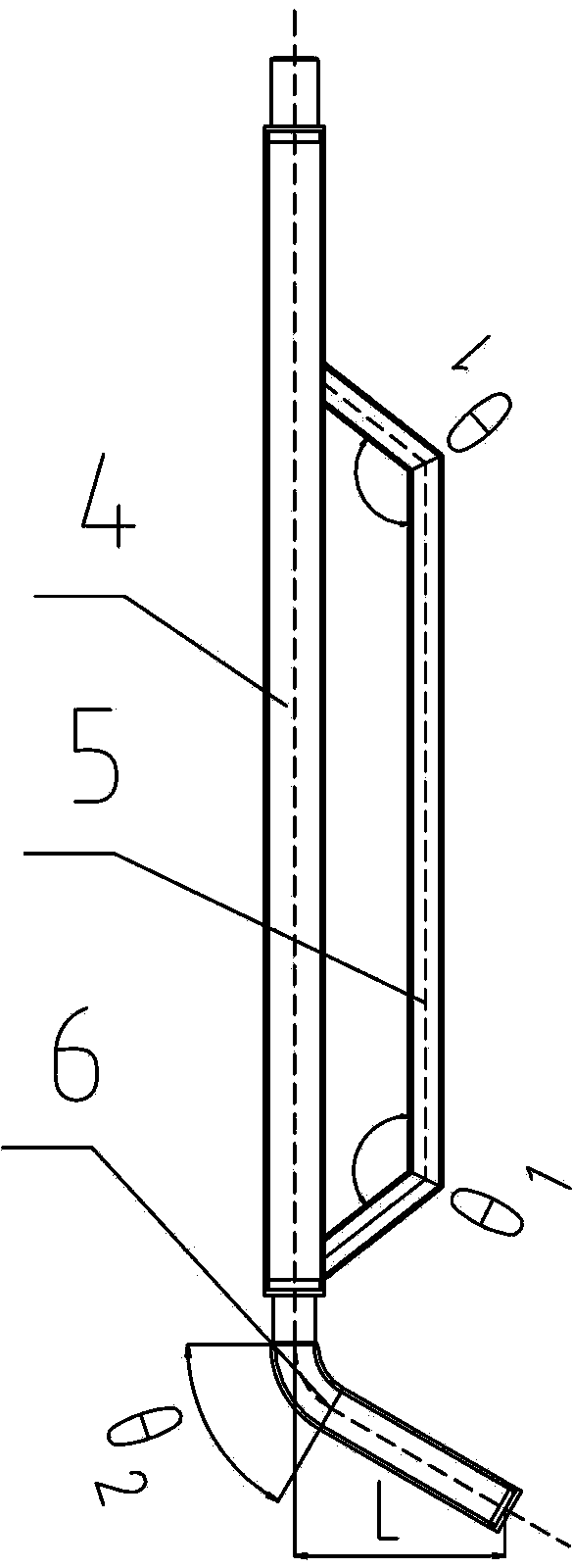

[0037] Such as figure 1 ~As shown in Figure 4, the stirring reaction device provided by the present invention includes a stirring tank 1, a rotating shaft 2, a paddle 3, a first spoiler 4, a trapezoidal spoiler 5 and a spoiler elbow 6; the rotating shaft 2 is provided with three The layered paddles are the top layer, the middle layer and the bottom layer. Each layer has three paddles, which are designed at intervals of 120 degrees on the circumference. A heat transfer half-pipe jacket 7 is arranged on the periphery of the stirred tank 1 .

[0038] In this embodiment, the diameter of the stirred tank is 1200mm, and the backbend angle, upturned angle and blade break angle of the bottom of the stirred tank are respectively 31°, 10°, and 14°, and the diameter of the blade is 600mm; The backbending angle, upturning angle and blade breaking angle of the middle and top blades are 32°, 10°, and 14° respectively, and the diameter of the blade is 450mm; the distance between the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com