Transducer-type vacuum gauge

A sensor and vacuum gauge technology, applied in the field of sensor-type vacuum gauges, can solve problems such as increasing operating costs, and achieve the effects of reducing operating costs, being easy to use, and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

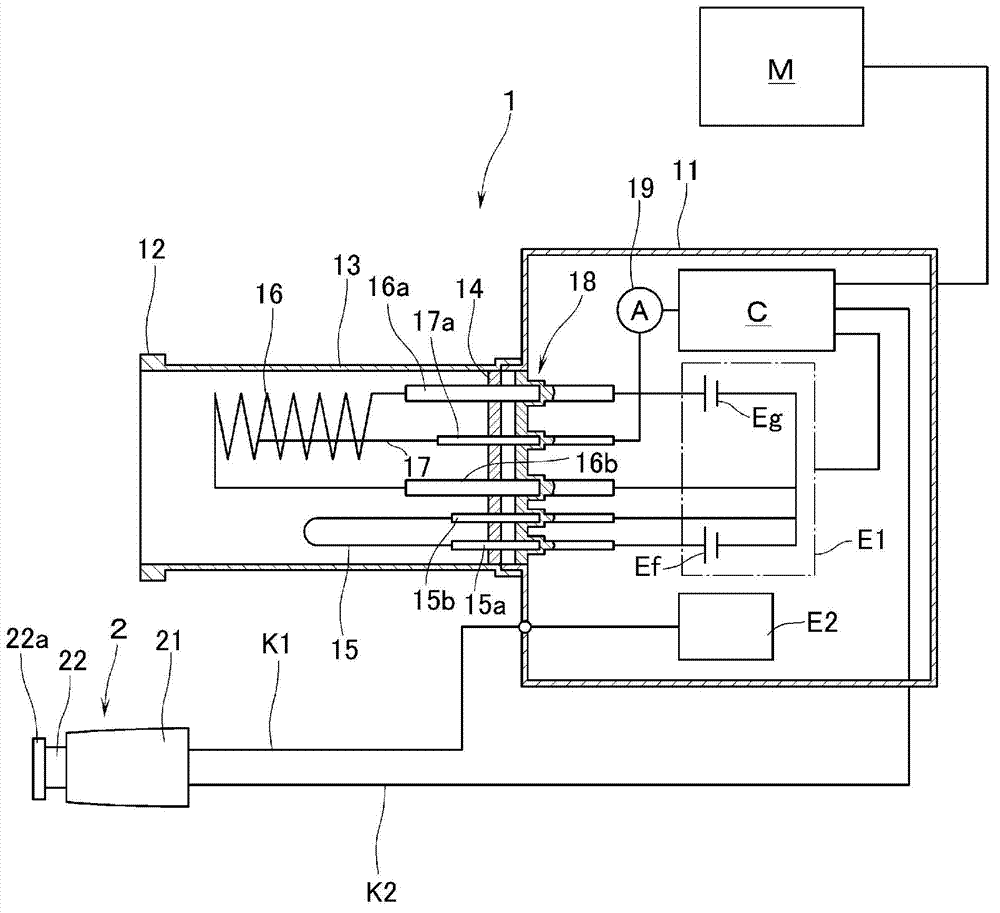

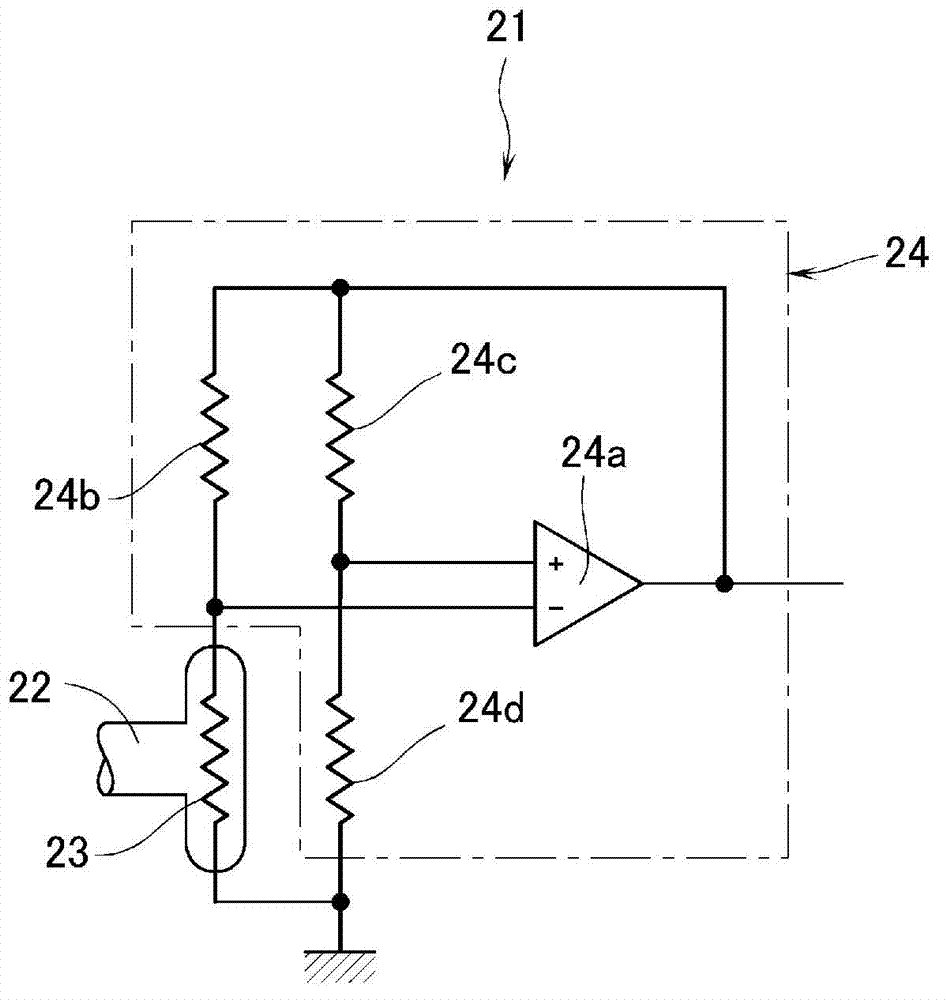

[0020] Hereinafter, with reference to the accompanying drawings, a vacuum processing device such as a sputtering device or a CVD device is used as a measurement object sealed and stored, and a case where the pressure measurement is carried out in the vacuum processing device is taken as an example to describe the sensor-type vacuum sensor according to the embodiment of the present invention. count.

[0021] refer to figure 1 , VC is a vacuum chamber of a vacuum processing device. The vacuum chamber VC is set to have a vacuum exhaust system composed of a turbomolecular pump P1 and a diaphragm pump P2 on its back pressure side via a pipeline VL, and can be pumped from atmospheric pressure to high vacuum. vacuum. A mounting portion CP1 having a flange is formed on a side wall of the vacuum chamber VC, and the main body 11 of the sensor-type vacuum gauge 1 of the present embodiment is detachably mounted on the mounting portion CP1. The main body 11 is composed of a casing, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com