Reactor and a method of purifying a process solution

A reactor and solution technology, applied in the direction of chemical instruments and methods, process efficiency improvement, chemical/physical/physical-chemical stationary reactors, etc. reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

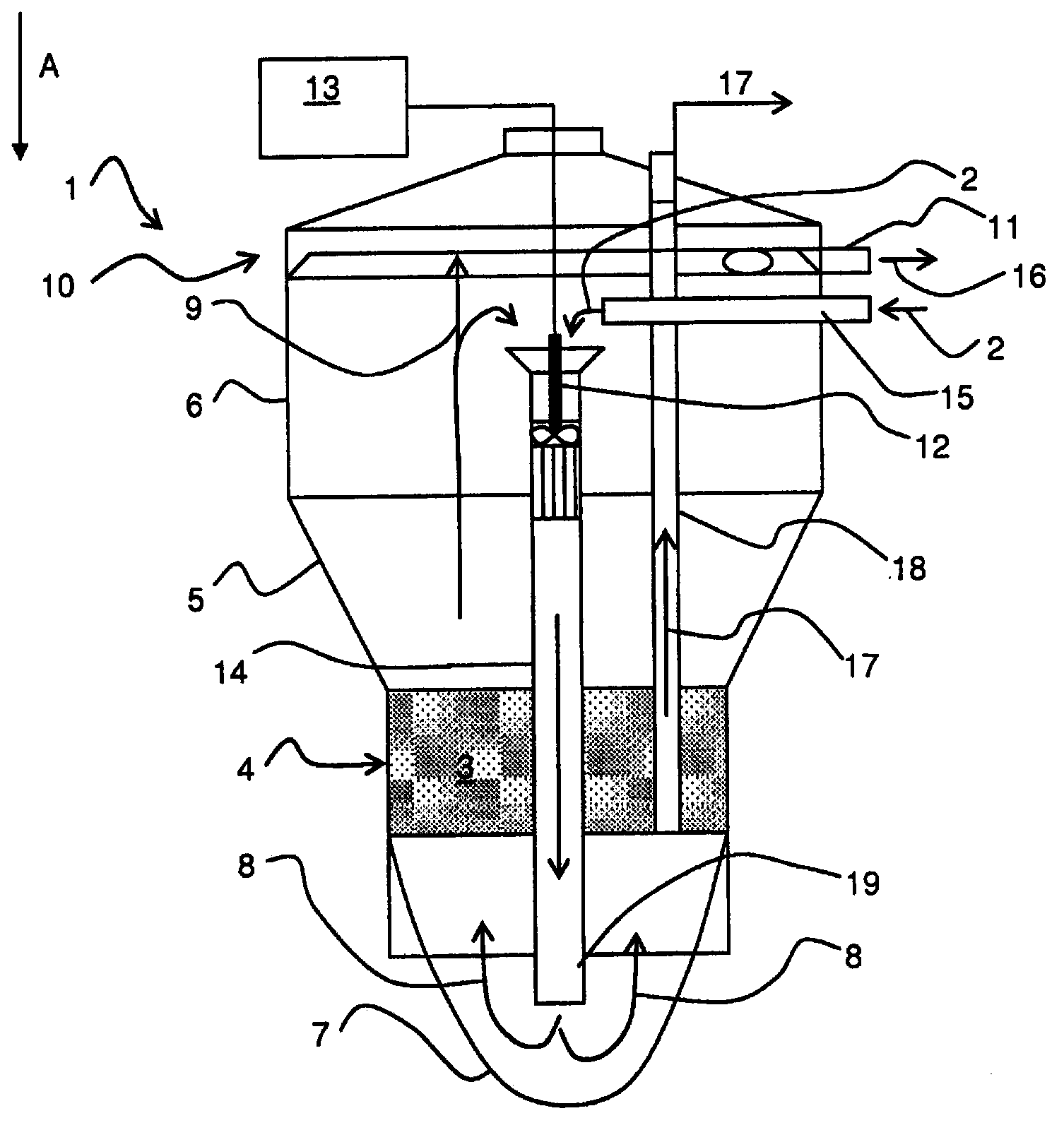

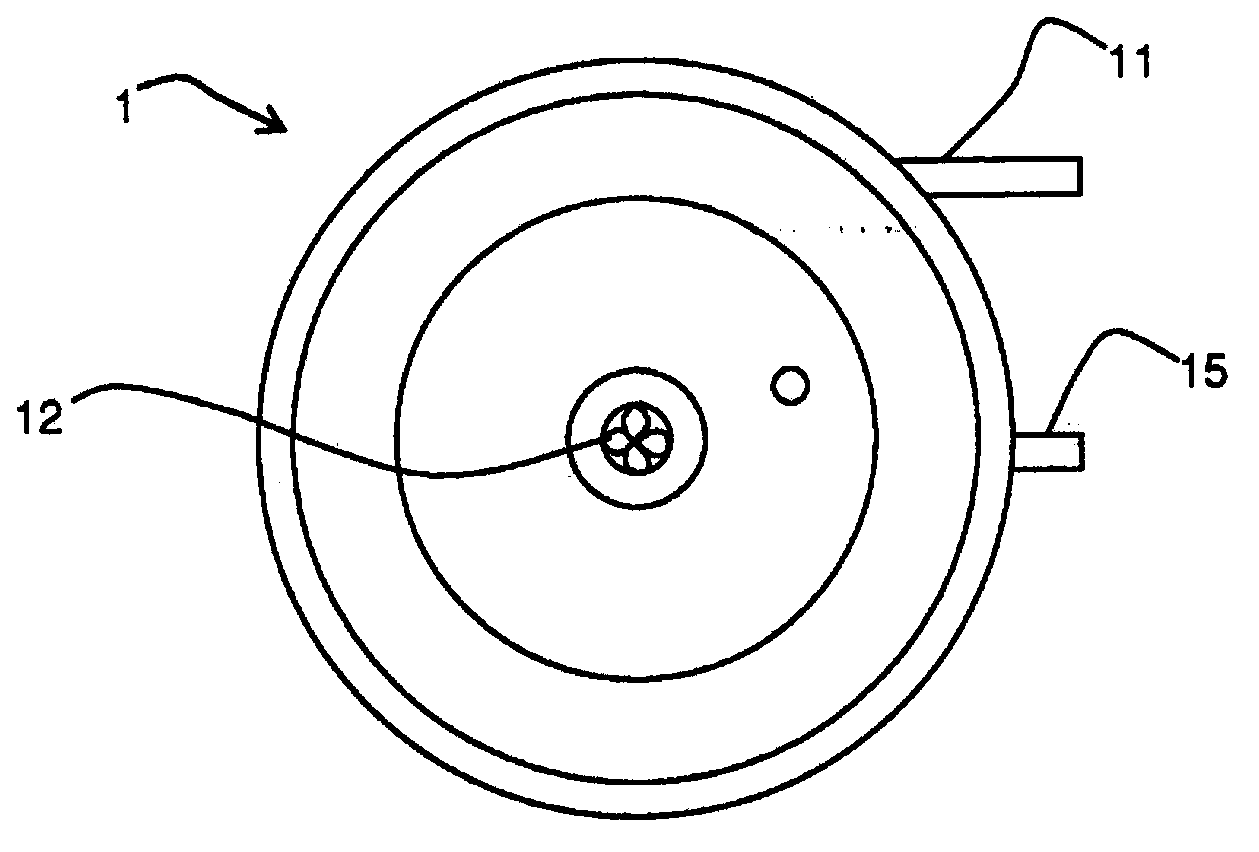

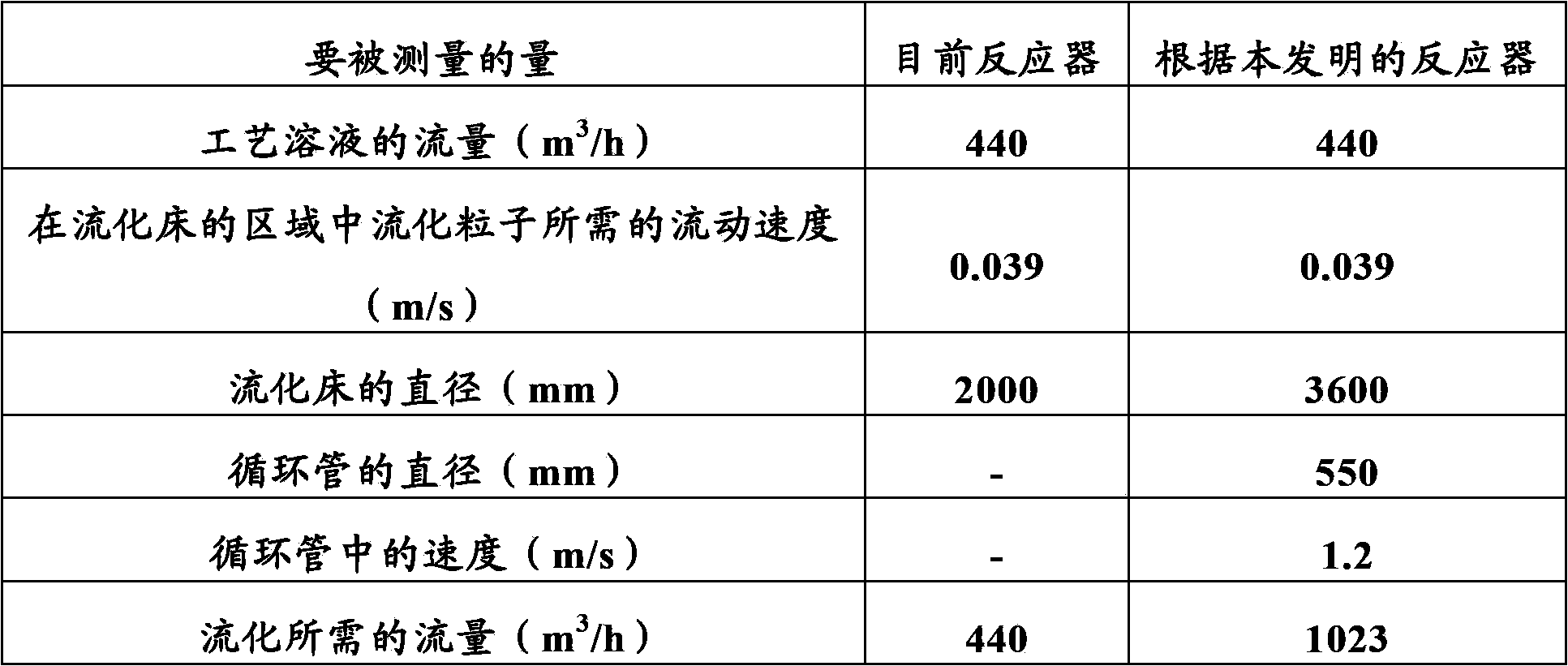

[0021] Figure 1a Shows a reactor 1 according to the invention in which a liquid process solution 2 and solid matter are treated such that the powdered solid matter forms a fluidized bed 3 with the liquid and simultaneously with the process to be purified which is fed into the reactor Solution 2 reacts. In the fluidized bed 3, the flow fluidizes the solid matter reacting with the solution. According to this example, the displacement reaction in question is the removal of cadmium from a solution bearing zinc, wherein the aqueous solution, ie the solution bearing cadmium of the substance to be displaced, flows through a bed of zinc powder. Now, a reaction proceeds according to which zinc dissolves in the solution and cadmium is removed from the solution. In the lower part of the reactor, ie the cylindrical reaction part 4, a fluidized bed 3 is formed. From this lower part rises a conical upwardly widening calming part 5 and another cylindrical clarifying part 6 in order to lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com