Caffeinless coffee

A caffeine-free and coffee-free technology, which is applied in the fields of coffee, coffee alkali reduction, food science, etc., can solve the problems of weak coffee taste and damaged coffee flavor, and achieve the effect of preventing the aroma from decreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1 Manufacture of fermented coffee beans

[0068] Fermented coffee beans are manufactured through the following processes:

[0069] 1) The steam treatment process of steaming the coffee fruit for 15-30 seconds at 90-110°C,

[0070] 2) The process of cooling to 30-40°C,

[0071] 3) Adding 0.05 to 0.5% by weight of adipic acid or lactic acid per unit weight of coffee cherries to adjust the pH of the coffee cherries to pH 3 to 4,

[0072] 4) Simultaneously with or after the pH adjustment step, a microorganism attachment step for attaching fermentation microorganisms is performed,

[0073] 5) Carry out the cultivation process at 30-40°C for 48-72 hours,

[0074] 6) The drying process of drying the cultivated coffee cherries,

[0075] 7) The process of separating and refining coffee pulp from coffee seeds to obtain fermented coffee beans.

[0076] That is, 100 kg of coffee fruit was prepared, and the above process 1) was performed at a temperature of 100° C. fo...

Embodiment 2

[0077] Example 2 Production of Decaffeinated Coffee Beans (1)

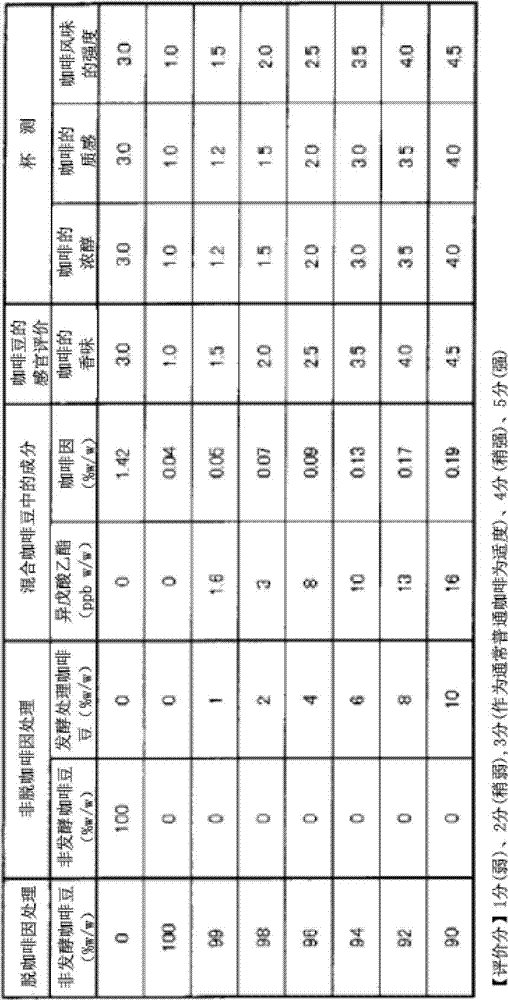

[0078] As coffee beans to be subjected to flavor enhancement, Arabica coffee beans from Brazil were used. The green coffee beans are treated with water for decaffeination, so that the caffeine content in the green beans is reduced from 1.42% to 0.04%. After mixing the decaffeinated green beans and the fermented coffee beans (green beans) produced in Example 1 in the ratio shown in Table 1, use a horizontal (horizontal) drum roaster (hot air type) to roast at a medium depth Roast (L value: 19.5) for roasting. The aroma of the obtained roasted coffee beans (decaffeinated coffee beans) was sensory evaluated, and at the same time, the content of ethyl isovalerate and the caffeine content in the roasted coffee beans (mixed beans) were measured. The ethyl isovalerate content and the caffeine content were measured by the following methods.

[0079] (Determination method of ethyl isovalerate)

[0080] After the roas...

Embodiment 3

[0121] Embodiment 3 Manufacture of decaffeinated coffee beans (2)

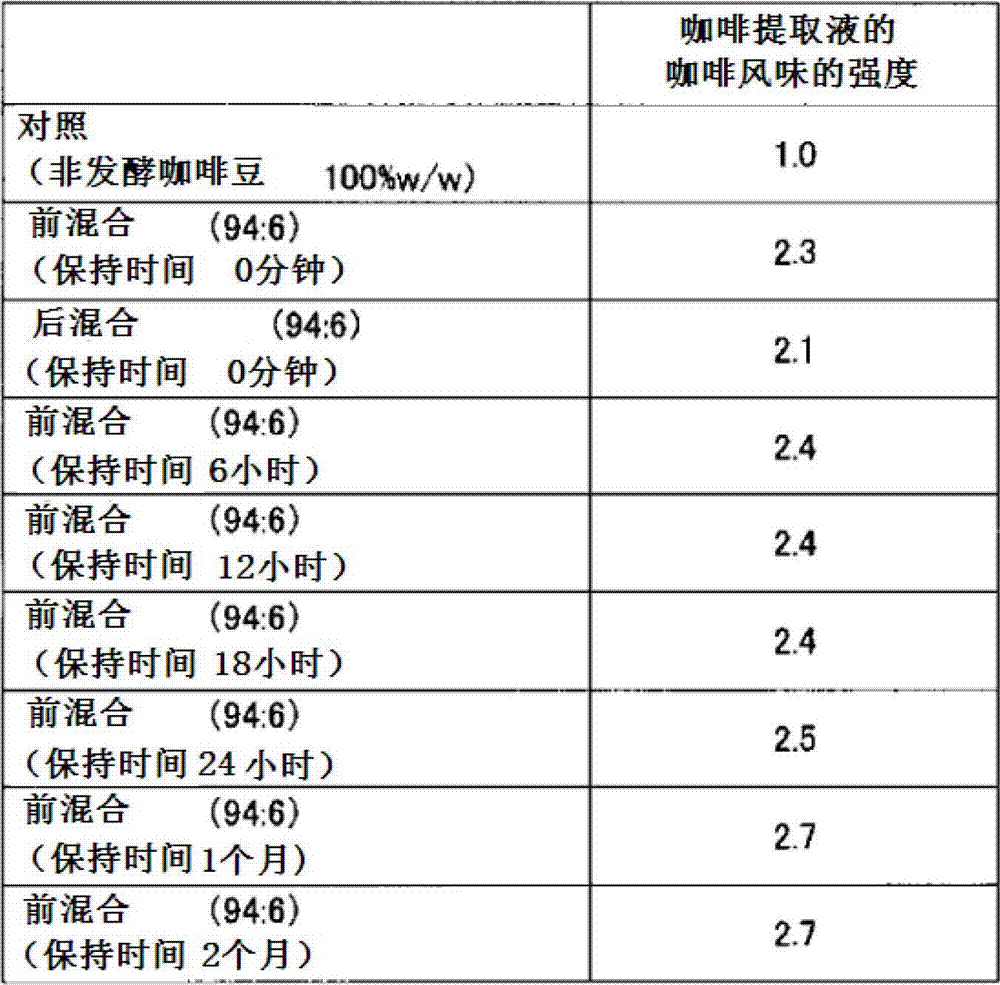

[0122] As in Example 2, decaffeinated green beans (non-fermented coffee beans) and fermented green beans (fermented coffee beans) were used. These beans were mixed at a ratio of non-fermented coffee beans:fermented coffee beans=94:6 (%w / w). After keeping the mixed green beans in the airtight container for a certain period of time, use a horizontal (horizontal) drum roaster (hot air type) to perform roasting with medium-depth roasting (L value: 19.5) to obtain roasted mixed beans (pre-mixed). The mixed green beans were kept at room temperature for 6 hours, 12 hours, 18 hours, and 24 hours, and refrigerated (5° C.) for 1 month and 2 months. The same 100% w / w decaffeinated coffee with roasted non-fermented green coffee beans was used as a control, and the coffee extract obtained from roasted coffee beans was sensory evaluated for the intensity of its coffee flavor. In addition, coffee beans obtained by roasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com