Intelligent component optimizer for solar photovoltaic cell panel and control method thereof

A photovoltaic cell panel and control method technology, applied in the direction of photovoltaic power generation, electrical components, control/regulation systems, etc., can solve problems such as inconsistent output of photovoltaic cell panels, affecting photovoltaic cells, and failure of photovoltaic cell panel components to achieve good application Foreground, optimal effect of power generation utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

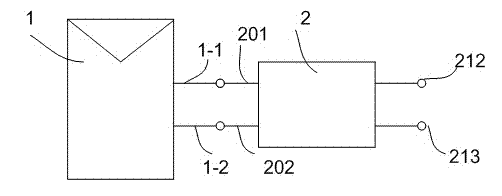

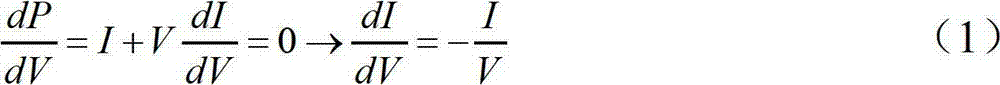

[0028] like figure 1 and figure 2 As shown, the component optimizer 2 of the intelligent solar photovoltaic panel provided by the present invention introduces the high-frequency DC switching power supply technology into the distributed photovoltaic power generation system, and can select the DC conversion topology or boost mode according to the DC conversion adjustment margin , or step-down mode, to realize the stable operation of the photovoltaic panel at the maximum power point. The controller of the module optimizer takes the high-performance and high-speed DSP processor as the core, and observes the input voltage and current of the front stage and the output voltage and current of the rear stage in real time. The control method is used to select the working mode of the component optimizer 2, so that under any irradiance conditions, there will be no mismatch pheno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com