Device for testing dynamic friction torque of precise micro rolling bearing

A rolling bearing and friction torque technology, which is applied in the field of precision miniature rolling bearing dynamic friction torque testing devices, can solve the problems of large dynamic friction torque test errors and difficulty in truly reflecting the actual dynamic friction torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

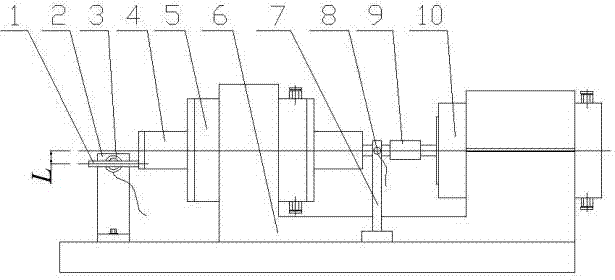

[0018] see figure 1 and figure 2 , the precision miniature rolling bearing dynamic friction torque testing device, including machine base (6), aerostatic suspension bearing seat (5), two sets of tested bearings (20), driving electric spindle (10), pressure sensor (3) and A speed sensor (8), characterized by:

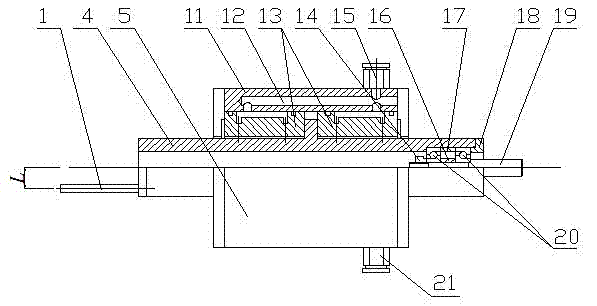

[0019] 1) The two sets of tested bearings (20) are placed in the center hole of the suspension shaft (4) in the aerostatic suspension bearing seat (5), and the center holes of the two sets of tested bearings (20) are connected with a rotating Mandrel (19) is fixedly socketed;

[0020] 2) The rotating mandrel (19) is connected to drive the electric spindle (10) through a rubber hose flexible coupling (9);

[0021] 3) Install the pressure sensor (3) near the left end of the suspension shaft (4), and install the speed sensor (8) near the right end of the suspension shaft (4).

Embodiment 2

[0023] The dynamic friction torque testing device for precision miniature rolling bearings is characterized in that: the aerostatic suspension bearing seat (5) and the driving electric spindle (10) are installed on the base (6), and according to the principle of aerostatic bearings, Use compressed air to completely suspend the suspension shaft (4), and completely isolate it together with the tested bearing (20) from other surrounding external parts, so as to avoid any influence of contact on the test results.

[0024] The device for testing the dynamic friction torque of precision miniature rolling bearings is characterized in that: the test bearing ( 20) Apply axial preload.

[0025] The dynamic friction torque testing device for precision miniature rolling bearings is characterized in that a lever (1) is installed on the left end of the suspension shaft (4), and the lever (1) is pressed against the pressure sensor on the pressure sensor (3). (3), the pressure sensor (3) is ...

Embodiment 3

[0027] figure 1 As shown, the precision miniature rolling bearing dynamic friction torque test device includes: the air static pressure suspension bearing seat (5) and the driving electric spindle (10) are installed on the machine base (6), and the suspension shaft (4) It is completely suspended and connected with a rubber hose flexible coupling (9). At the same time, a lever (1) installed on the left end of the suspension shaft (4) is pressed against the pressure sensor ( 3) on.

[0028] The aerostatic suspension bearing seat (5) mentioned above, such as figure 2 As shown, it includes: the compressed air passes into the air inlet nozzle (15) installed on the casing (11), passes through the air flow channel (12), enters the air static pressure bearing (13) and suspends the suspension shaft (4), from The air outlet (21) leads to the outside world. The two sets of test bearings (21) installed in pairs are installed in the suspension shaft (4), and the width difference betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com