Collecting pipe and parallel flow evaporator using same

A collecting tube and evaporator technology, which is applied in the field of parallel flow evaporators, can solve the problems of low product welding pass rate, high production cost, and affecting product performance, and achieve the goal of improving universality, saving installation man-hours, and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

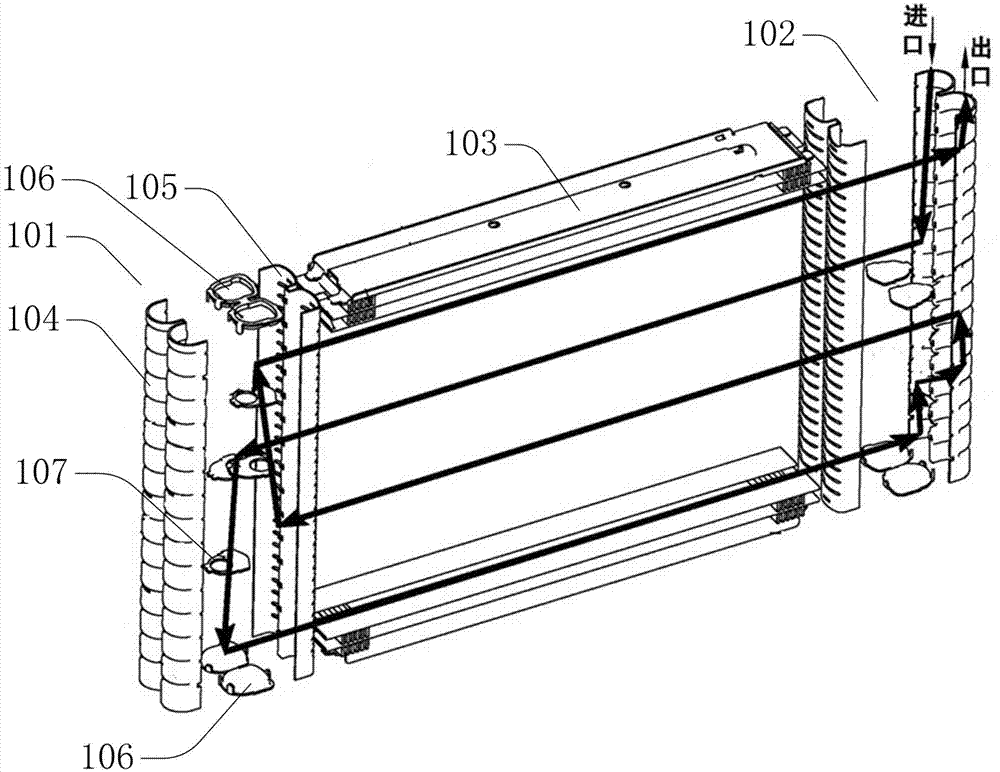

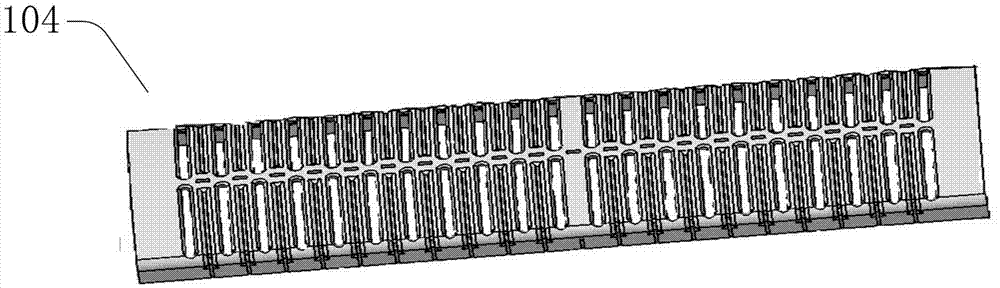

[0029] The specific implementation of the header provided by the present invention and the parallel flow evaporator using the header will be described in detail below with reference to the accompanying drawings.

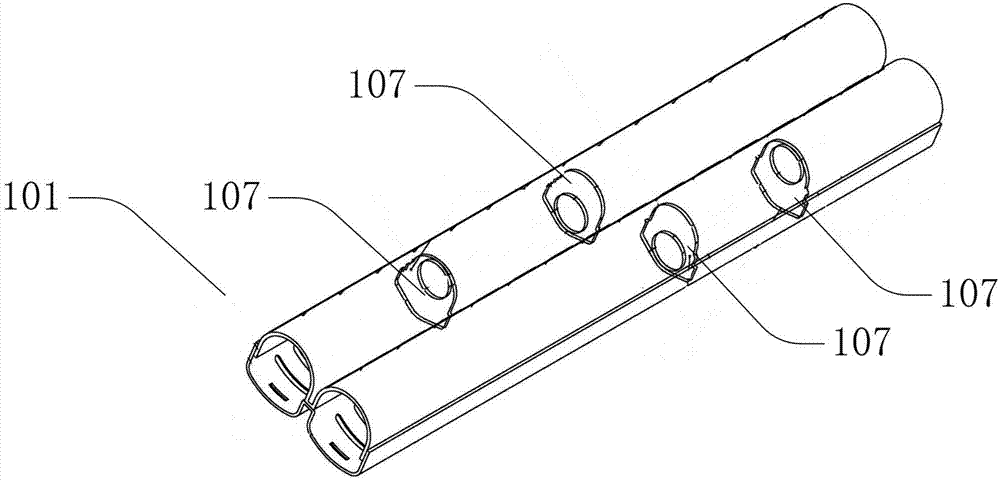

[0030] Figure 2A Shown is the perspective schematic view of the structure of the collector of the present invention, Figure 2B shown as Figure 2A A schematic cross-sectional view along the A-A direction. see Figure 2A and Figure 2B As shown, the header 1 includes a first lumen 2 and a second lumen 3 . The first lumen 2 and the second lumen 3 are parallel to each other, and the axes of the first lumen 2 and the second lumen 3 are parallel to the length direction of the header 1 . In this embodiment, preferably, the first lumen 2 and the second lumen 3 are integrally formed, for example, an "8"-shaped structure integrally formed, and the upper and lower parts of the "8"-shaped structure form a header The first lumen 2 and the second lumen 3 of 1. The one-pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com