Mud-modifying equipment with physical method

A physical method and mud technology, applied in the direction of chemical instruments and methods, dissolution, wellbore/well components, etc., can solve the problems of large chemical pollution, high cost, and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

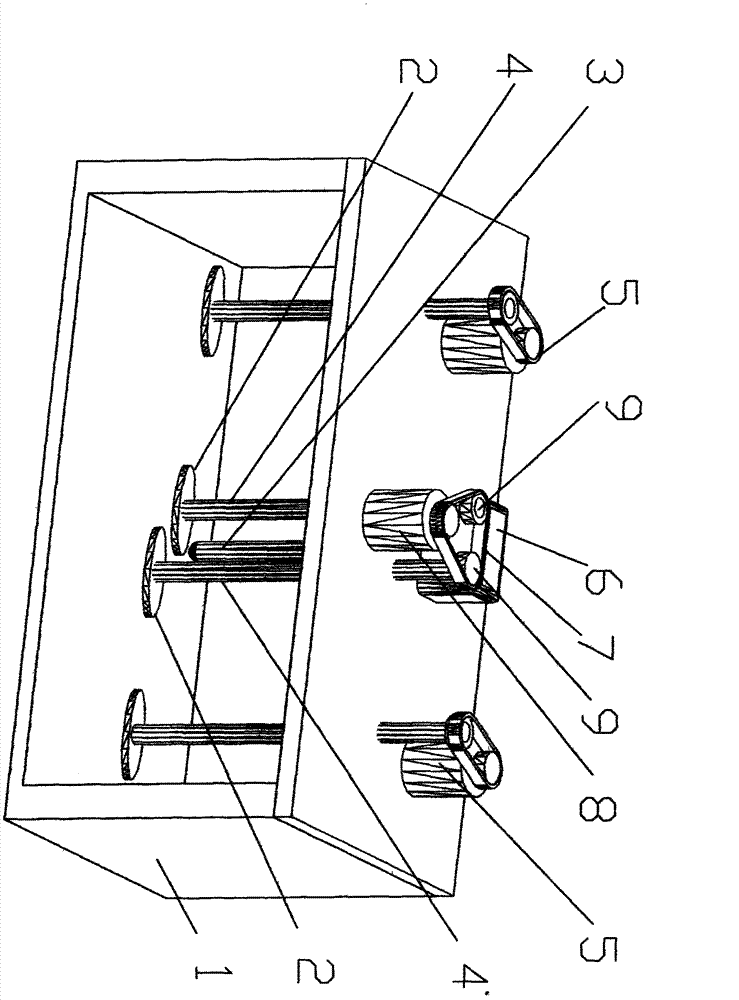

[0011] In the figure, two agitators 5 are arranged on the left and right sides of the mud pool 1; chemical additives are added to the mud pool 1, and two dispersion shafts 4 are arranged in the middle of the mud pool 1, and an impeller 2 is respectively arranged at the lower end of each dispersion shaft 4, and an impeller 2 is arranged at the upper end respectively. A drive wheel 9 is set; and a dispersing motor 8 is set above the middle part of the mud pool, and the dispersing motor 8 cooperates with the transmission of the two drive wheels 9 through the drive belt 7; The launch end 3 of 6 goes deep into the mud pool 1 bottom.

[0012] The transmitting end 3 of the ultrasonic generator and the two dispersing shafts 4 are arranged in a triangle; the two impellers 2 are arranged one above the other in a staggered manner.

[0013] When the equipment is working, two agitators 5 stir the mud, and the two dispersion shafts 4 and two impellers 2 rotate under the drive of the dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com