High-expansibility naked eye suspension adhering system and method

A high-expansion, subsidized technology, applied in drilling equipment and methods, earth-moving drilling, wellbore/well components, etc., can solve the problems of many consumable materials, low construction reliability, complex construction process, etc., to reduce emissions , The effect of reducing drilling material consumption and optimizing well structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following description.

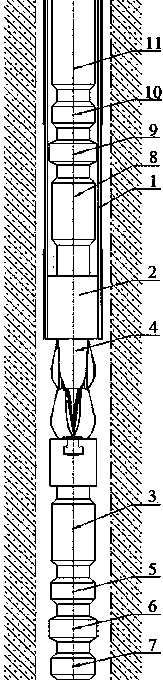

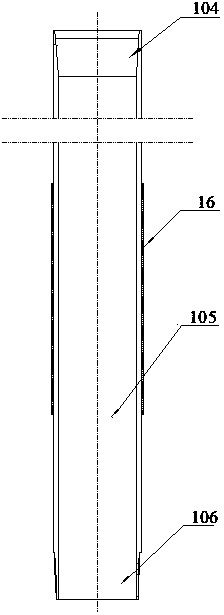

[0049] A high expansion rate naked eye suspension subsidy system, such as figure 2 , Figure 9 and Figure 10 As shown, it includes a supplementary pipe 1 and a tool pipe string. The tool pipe string is composed of an auxiliary hydraulic cylinder 2, a lower hydraulic cylinder 3, a hydraulic variable diameter expansion cone 4, a lower drill pipe adapter 5, and a lower hydraulic anchor 6. , The lower pressure ball seat 7, the upper hydraulic cylinder 8, the upper hydraulic anchor 9, the upper drill pipe conversion joint 10, the drill pipe 11 and the upper pressure ball seat 14 are formed.

[0050] Such as Figure 6 and Figure 7 As shown, the hydraulic variable diameter expansion cone 4 includes an upper claw plate 405, a lower claw plate 401, an upper expansion block 403,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com