Wind blocking board in heat preservation box

A technology for a thermal insulation box and a windshield, which is applied in the field of windshields, can solve the problems of large thread swaying, high waste thread consumption, and many broken ends, etc. Solve the effect of broken heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The windshield in the thermal insulation box of the present invention will be further described in detail below through specific examples.

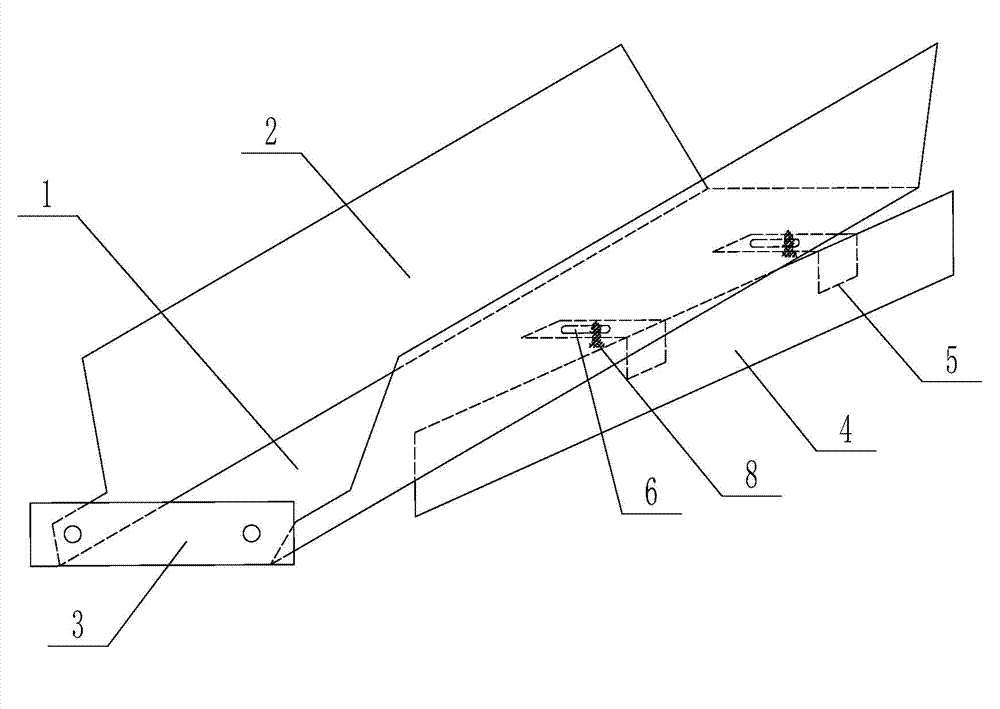

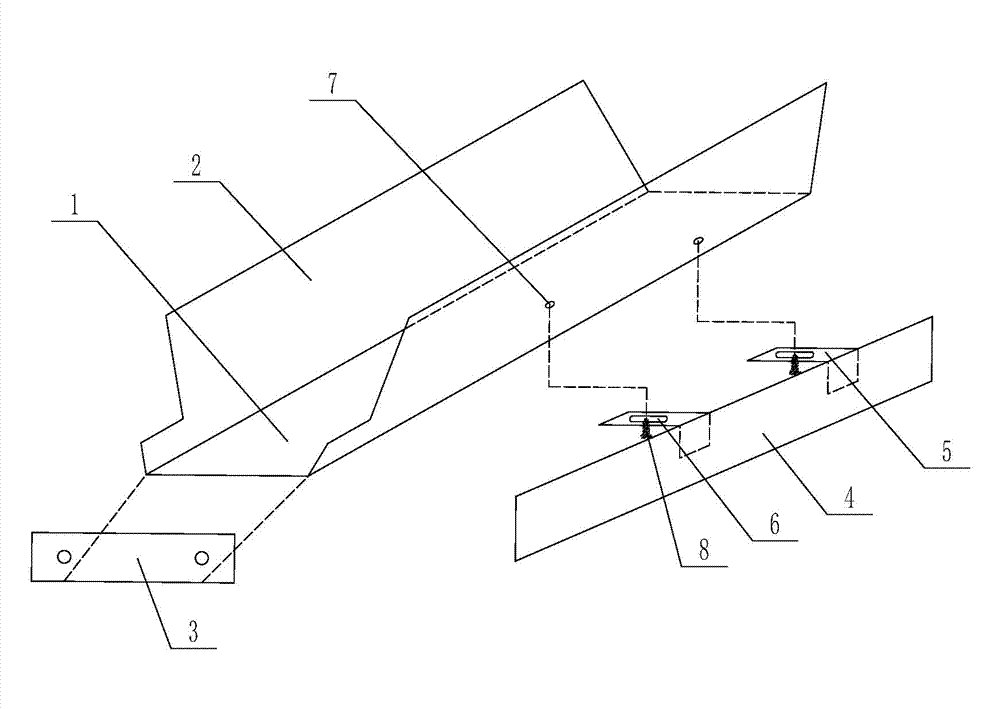

[0011] Such as figure 1 , figure 2 As shown, the windshield in the heat preservation box includes a trapezoidal body with a wide top and a narrow bottom made of a bottom plate 1 and two outwardly inclined side plates 2. A connecting plate 3 is provided on the left side of the bottom plate 1. The included angle between the side plates 2 and the bottom plate 1 is between 125° and 135°, and the lower part of the bottom plate 1 is provided with a strip-shaped air distribution plate 4, which is vertically arranged with the bottom plate 1, and the air distribution plate 4 The included angle with the right end face of the trapezoid is between 55° and 75°.

[0012] The connection structure between the air distribution plate 4 and the bottom plate 1 is: the side of the air distribution plate 4 is fixed with an adjustment plate 5, the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com