Automatic control multi-spray-head electrostatic spinning equipment

An automatic control and electrospinning technology, which is applied in the direction of spinneret assemblies, textiles and papermaking, filament/thread forming, etc., can solve the problems that nanofiber membranes are not easy to mass-produce, and achieve high automation and high production efficiency The effect of improving and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

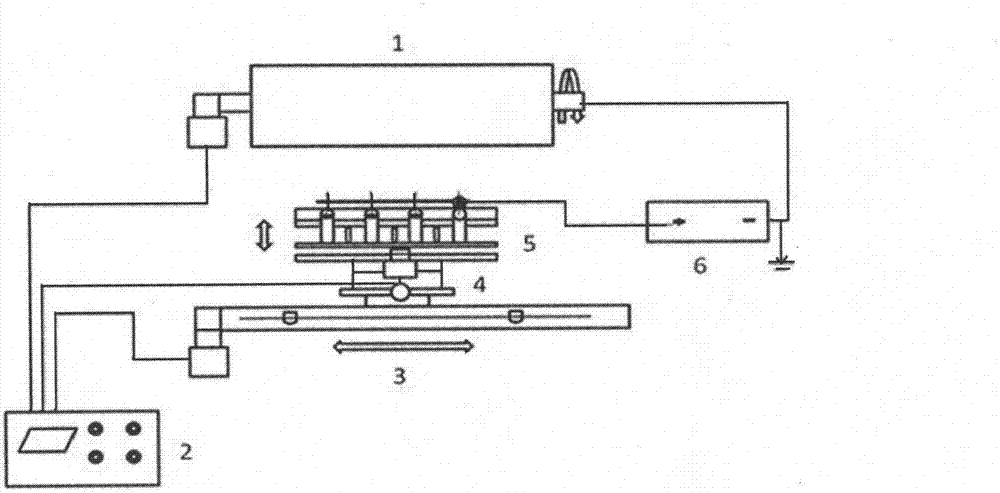

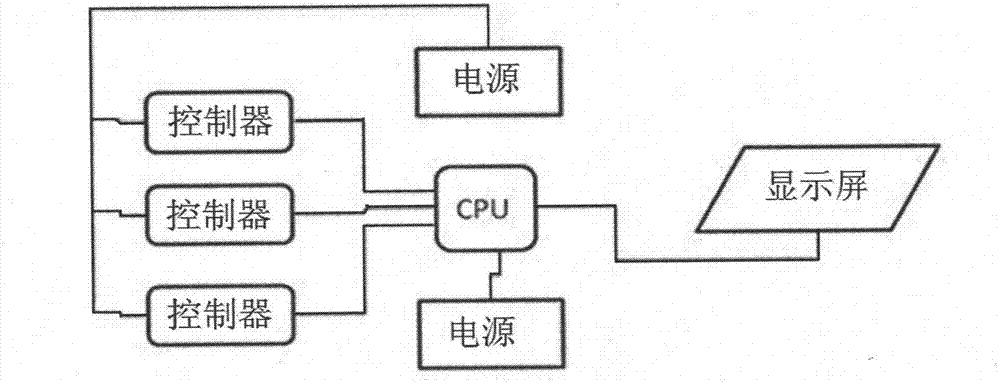

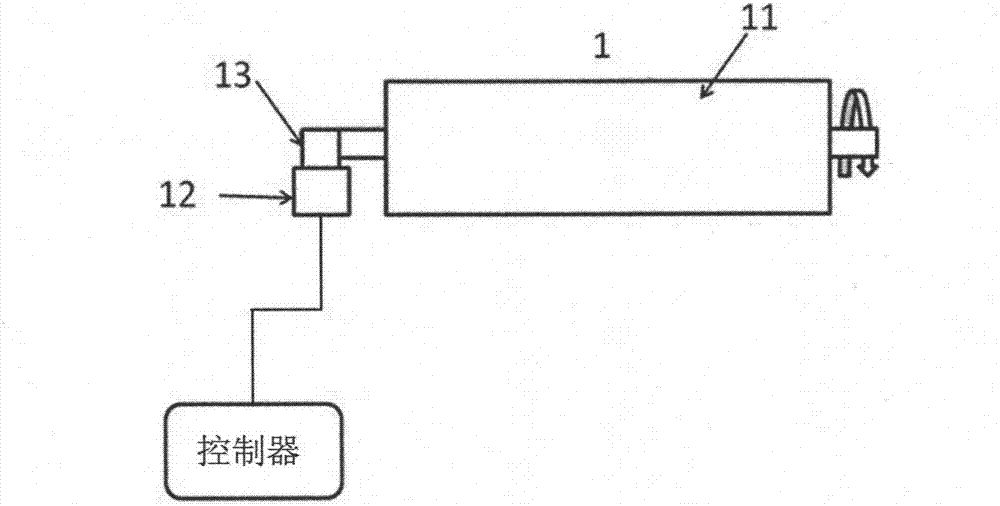

[0032] Such as figure 1 As mentioned above, a kind of automatically controlled multi-nozzle electrospinning equipment in this embodiment includes a receiving device 1 for receiving polymer fibers, the negative pole of the high-voltage electrostatic generator 6 is connected to the receiving device 1, and the high-voltage electrostatic generator 6 is connected to the receiving device 1. The negative electrode is connected to a self-cleaning multi-nozzle device 7 with at least one nozzle. The self-cleaning multi-nozzle device 7 is located below the receiving device 1, and the receiving distance between the self-cleaning multi-nozzle device 7 and the receiving device 1 is 6-35 cm. Under the control of the control unit 2, the multi-channel precision liquid supply pump 5 provides the spinning solution for the self-cleaning multi-nozzle device 7 at a set injection speed, and the spinning solution forms a jet flow under the action of the self-cleaning multi-nozzle device 7, and the jet...

Embodiment 2

[0049] The device in the present embodiment is similar to Embodiment 1, and the difference is that the number of holes 56 on the first insulating plate 10 is 8, and the spacing is 1.5 centimeters; the diameter of the spinneret 59 is 0.8 centimeters; The diameter of the holes on the bakelite board 58 is 0.8 centimeters, the number is 8, and the spacing is 1.5 centimeters.

[0050] Under the conditions of room temperature 25°C and humidity 45%, the polyvinyl alcohol (PVA) solution with a mass fraction of 12% is sucked into a 10 ml syringe, placed on the multi-channel precision liquid supply pump 5, and the multi-nozzle static electricity of the automatic control is adjusted. The process parameters of the spinning equipment are as follows:

[0051] The winding speed of receiving device 1 is 20 / min;

[0052] The back-and-forth linear speed of the dust-proof type lateral movement slide table 3 is 80 meters / minute;

[0053] The injection speed of the multi-channel precision liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com