Granular pesticide fertilizer, and preparation method and application thereof

A technology for granules and granular fertilizers, which is applied in the field of granules, medicinal fertilizers and their preparation, can solve the problems of high hardness of extruded granulated granules, decomposition and gasification of pesticide components, and affecting the release of pesticide components, so as to improve the efficacy of pesticides, Avoid the effect of uneven pesticide content and good efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

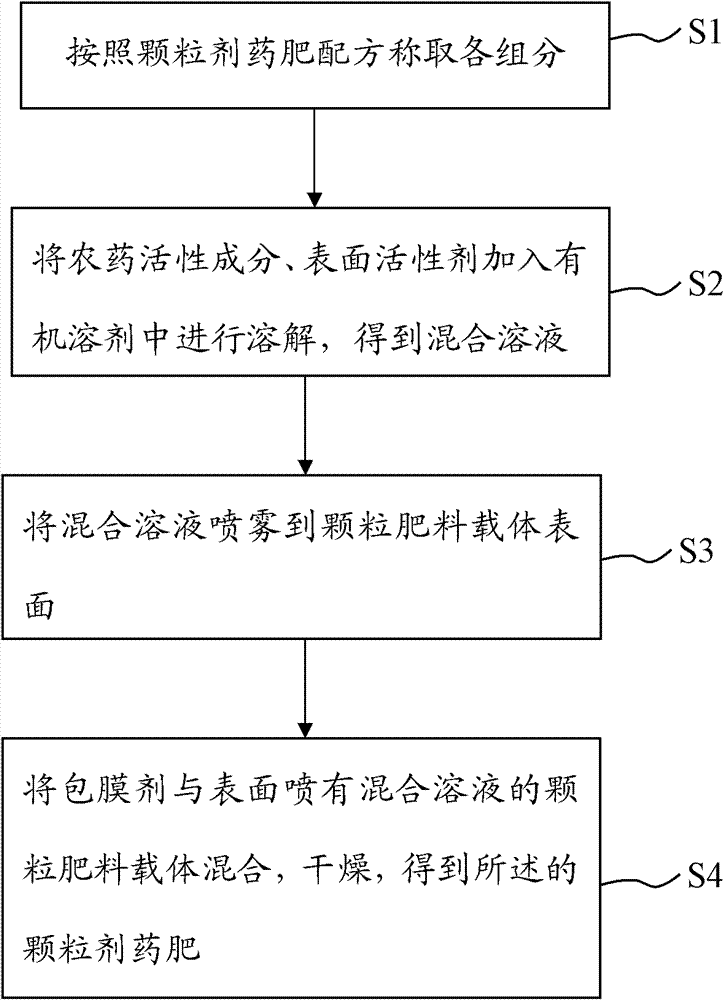

[0044] The embodiment of the present invention also provides the preparation method of above-mentioned granule medicinal fertilizer, the technological process of this method please refer to figure 1 . The granule medicinal fertilizer comprises the steps of:

[0045] S1: Weigh each component according to the above-mentioned granule medicinal fertilizer formula;

[0046] S2: adding the pesticide active ingredient and the surfactant into the organic solvent for dissolving to obtain a mixed solution;

[0047] S3: Spray the mixed solution onto the surface of the granular fertilizer carrier;

[0048] S4: Mix the coating agent with the granular fertilizer carrier sprayed with the mixed solution on the surface, and dry to obtain the granular fertilizer.

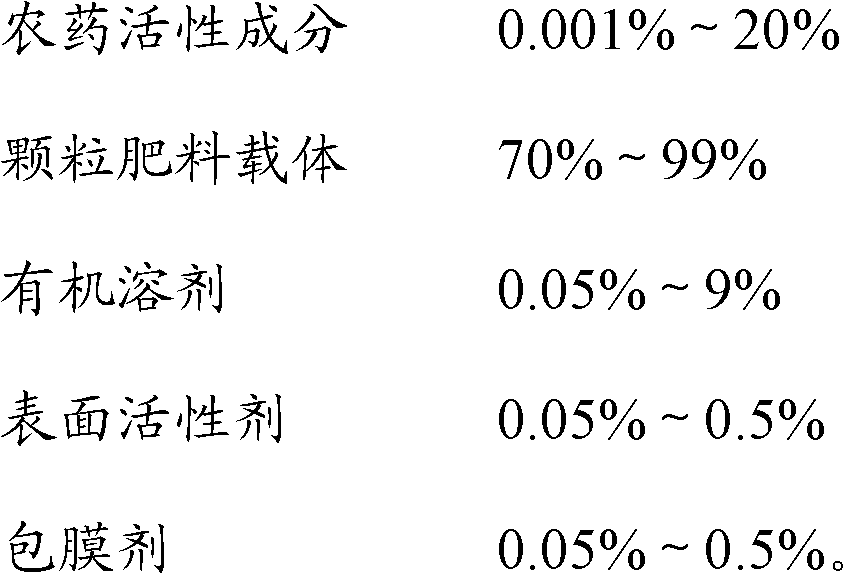

[0049] Specifically, in step S1 of the above method for preparing the granule medicinal fertilizer, the formula of the granule medicinal fertilizer, the content and type of each component in the formula, and the preferred technica...

Embodiment 1

[0057] The formula of 15% chlorpyrifos granule fertilizer: 154.7 kg of chlorpyrifos (97% by mass), 20 kg of turpentine, 3 kg of fatty alcohol polyoxyethylene ether (AEO-3), 817.3 kg of granular fertilizer carrier, 5 kg of carbon black kilogram.

[0058] The preparation method of this 15% chlorpyrifos granule medicinal fertilizer:

[0059] S11: Preparation of granular fertilizer carrier:

[0060] Weigh 600 kg of humic acid, 20 kg of ammonium sulfate, 10 kg of potassium dihydrogen phosphate, 30 kg of magnesium sulfate, 120 kg of boric acid, 60 kg of zinc sulfate, 5 kg of iron EDTA, 2 kg of copper sulfate, 1.5 kg of manganese sulfate, molybdenum acid 1.5 kg of sodium, 100 kg of water, and 50 kg of kaolin. Mix the components and granulate them with a compound fertilizer drum. The particles are round, dark brown to black, and 1.5 to 3.5 mm in diameter.

[0061] S12: First mix and heat chlorpyrifos, turpentine, and AEO-3 to fully dissolve to obtain a mixed solution;

[0062] S13:...

Embodiment 2

[0065] The formula of 0.5% abamectin granule medicinal fertilizer: 5.4 kilograms of abamectin (93% by mass), 40 kilograms of N-methylpyrrolidone, 803 kilograms of Tween, 946.6 kilograms of granular fertilizer carriers, white charcoal Black 5 kg.

[0066] The preparation method of this 0.5% abamectin granule medicinal fertilizer:

[0067] S21: Preparation of granular fertilizer carrier:

[0068] Weigh 310 kg of humic acid, 30 kg of ammonium sulfate, 20 kg of ammonium dihydrogen phosphate, 50 kg of magnesium sulfate, 150 kg of sodium octaborate tetrahydrate, 109 kg of sodium octaborate tetrahydrate, 20 kg of iron EDTA, 5 kg of copper EDTA, 3 kg of EDTA manganese, 3 kg of EDTA molybdenum, 200 kg of water, and 100 kg of kaolin. Mix the components and granulate them with a compound fertilizer drum. The particles are round, dark brown to black, and 1.5 to 3.5 mm in diameter.

[0069] S22: first mix and fully dissolve Abamectin, N-methylpyrrolidone, and Tween 80 to obtain a mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com