Algin high-tower compound fertilizer and preparation method thereof

A compound fertilizer and high tower technology, which is applied in fertilization devices, fertilizer mixtures, applications, etc., achieves the effects of good water solubility, stimulating root activity, and high technology content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

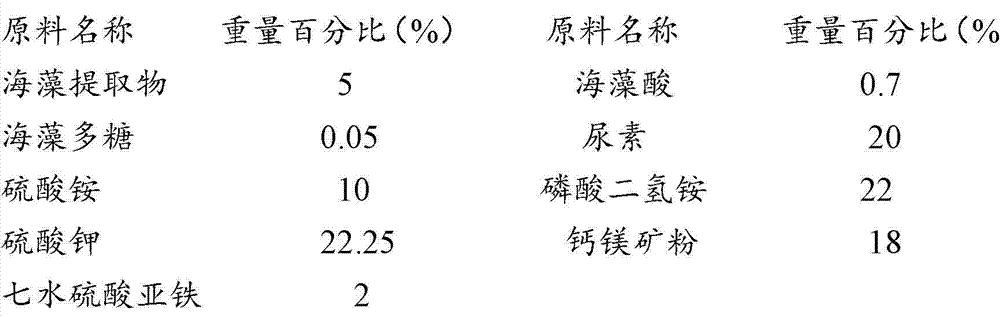

Embodiment 1

[0039]

[0040] The raw material seaweed extract obtaining method:

[0041] 1) Mechanically grind the fresh seaweed into a slurry mixture to achieve physical wall breaking;

[0042] 2) Add 3 kg of cellulase to the 997 kg slurry mixture obtained in step 1), and perform enzymatic hydrolysis at 40°C for 3 hours under stirring, so as to achieve enzymatic hydrolysis and wall breaking;

[0043] 3) Add 2 kg of alginate lyase to 1,000 kg of enzymatic hydrolysis solution obtained in step 2), and perform enzymatic hydrolysis at 50°C for 4 hours under stirring, so as to realize the conversion of alginate from large molecules to small molecules;

[0044] 4) The mixture obtained in step 3) is cooled to normal temperature, centrifuged at 3000-4000 rpm for 30 minutes, and then the supernatant is spray-dried, or the suspension is directly spray-dried at a high temperature of 150-175°C without centrifugation.

[0045] Preparation of Alginate High Tower Compound Fertilizer:

[0046] 50 kg ...

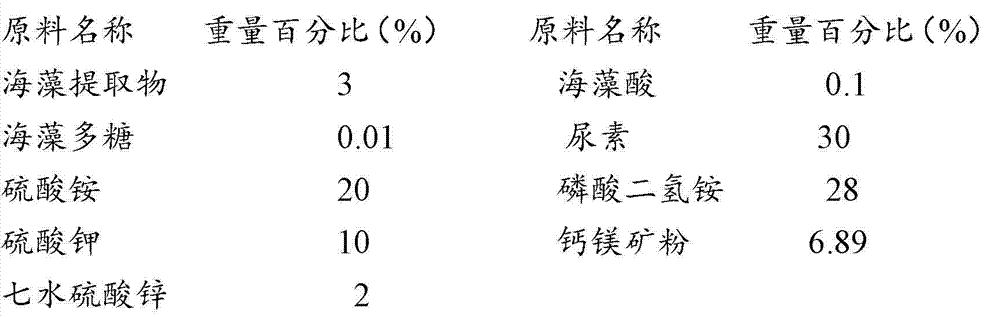

Embodiment 2

[0051]

[0052] The raw material seaweed extract obtaining method:

[0053] 1) Mechanically grind the fresh seaweed into a slurry mixture to achieve physical wall breaking;

[0054] 2) Add 2 kg of cellulase to the 998 kg slurry mixture obtained in step 1), and perform enzymatic hydrolysis at 40°C for 4 hours to achieve enzymatic hydrolysis;

[0055] 3) Add 4 kg of alginate lyase to 1000 kg of enzymolysis solution obtained in step 2), and perform enzymolysis at 50°C for 5 hours under stirring, so as to realize the conversion of alginate from large molecules to small molecules;

[0056] 4) The mixture obtained in step 3) is cooled to room temperature, centrifuged at 3000-4000 rpm for 30 minutes, and then the supernatant is spray-dried, or the suspension is directly spray-dried at a high temperature of 150-175°C without centrifugation.

[0057] Preparation of Alginate High Tower Compound Fertilizer:

[0058] 30 kg of seaweed extract, 1 kg of alginic acid, 0.1 kg of seaweed p...

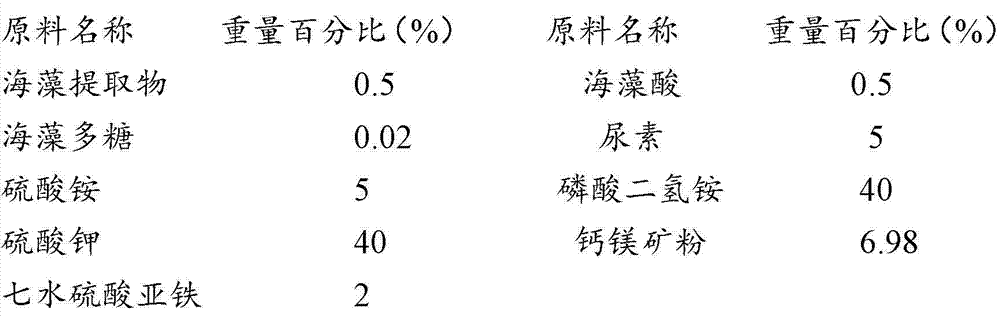

Embodiment 3

[0063]

[0064] The raw material seaweed extract obtaining method:

[0065] 1) Mechanically grind the fresh seaweed into a slurry mixture to achieve physical wall breaking;

[0066] 2) Add 4 kg of cellulase to the 995 kg slurry mixture obtained in step 1), and perform enzymatic hydrolysis at 40°C for 6 hours to achieve enzymatic hydrolysis;

[0067] 3) Add 3 kg of alginate lyase to 1000 kg of enzymolysis solution obtained in step 2), and perform enzymolysis at 50°C for 3 hours under stirring, so as to realize the conversion of alginate from large molecules to small molecules;

[0068] 4) The mixture obtained in step 3) is cooled to room temperature, centrifuged at 3000-4000 rpm for 30 minutes, and then the supernatant is spray-dried, or the suspension is directly spray-dried at a high temperature of 150-175°C without centrifugation.

[0069] Preparation of Alginate High Tower Compound Fertilizer:

[0070] 5 kg of seaweed extract, 5 kg of alginic acid, 0.2 kg of seaweed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com