Improved structure of vertical processing machine tool

A processing machine tool and improved technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient transportation and movement, weak rigid focus, difficult processing technology, etc., to save materials and resources, Simple manufacturing process and quick assembly

Inactive Publication Date: 2012-11-14

杜双全

View PDF12 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The purpose of the present invention is to provide an improved structure of a vertical processing machine tool to solve the problem of the prior art vertical processing machine tool with large weight and volume, weak rigid force point, large machine space but small processing space, and difficult manufacturing process. Problems of high cost and inconvenient transportation and movement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

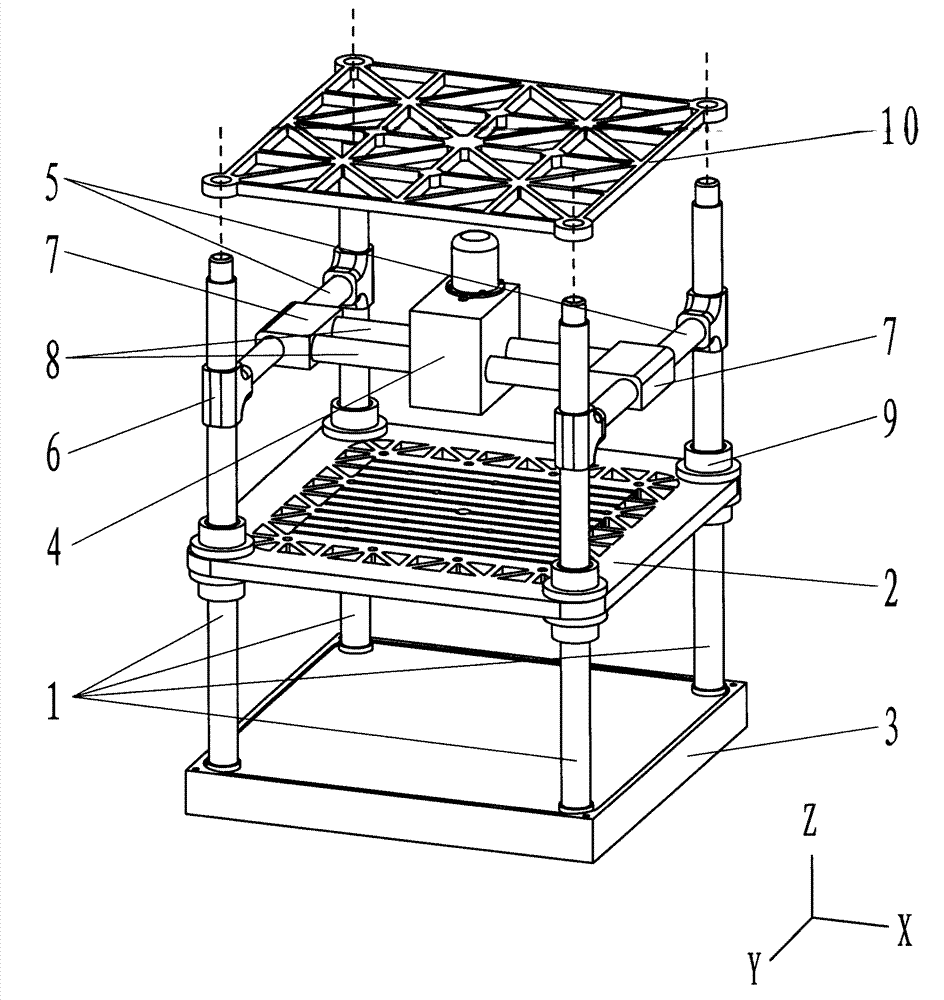

The invention discloses an improved structure of a vertical processing machine tool and aims to provide an improved structure which has relatively light weight and small volume, big processing space, simple manufacturing process, and low cost and can be independently disassembled and transpositionally assembled. The improved structure of the vertical processing machine tool comprises a pedestal, a machine body, a working platform, and a processing unit. An interlock frame style machine body composed by at least four guide rails is vertically fixed on the pedestal, and the upper part is provided with a stable frame. An X-direction kinematic pair, a Y-direction kinematic pair and the processing unit are arranged at the upper part of the machine body. The working platform is arranged on the machine body for moving in Z-direction. The routes of the guide rails in X, Y and Z directions are expanded to a maximum extent so as to obtain a larger processing space. The requirements for processing strength and precision are well guaranteed by adopting a reasonable structure and a lightweight guide rail pair with a cylndrical surface. The improved structure of the vertical processing machine tool is suitable for various ordinary and numerically controlled metal-cutting machine tools such as drill machines, drilling and milling machines, milling machines, boring and milling machines, multi-function machine tools, and vertical machining centres, is suitable for wide application, and plays a great role in saving resource.

Description

technical field [0001] The invention relates to a metal cutting machine tool, in particular to an improved structure of a vertical processing machine tool. Background technique [0002] At present, in the technical field of metal cutting machine tools, vertical milling machines, drilling and milling machines, vertical boring and milling machines, vertical machining centers, etc. are the most widely used vertical processing machine tools. The straight rigid column is used as the fuselage, and the processing unit is connected to the fuselage and the cross table that can move in the X direction and the Y direction is used to realize the cutting of the workpiece; but with the higher level of development of the world machine tool industry and the The trend of industrial products becoming larger and larger, the vertical processing machine tool with this traditional structure can no longer meet the required processing technology and requirements, coupled with the inevitable problem...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q1/01B23Q1/25B23Q5/34

Inventor 杜双全

Owner 杜双全

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com