Blowing and sucking type dust removal corn thresher with fork type screening

A threshing machine, corn technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems of low threshing efficiency, high fuel consumption, large smoke and dust, etc., to achieve improved service life, good threshing quality, and fast threshing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in detail below in conjunction with accompanying drawing of description:

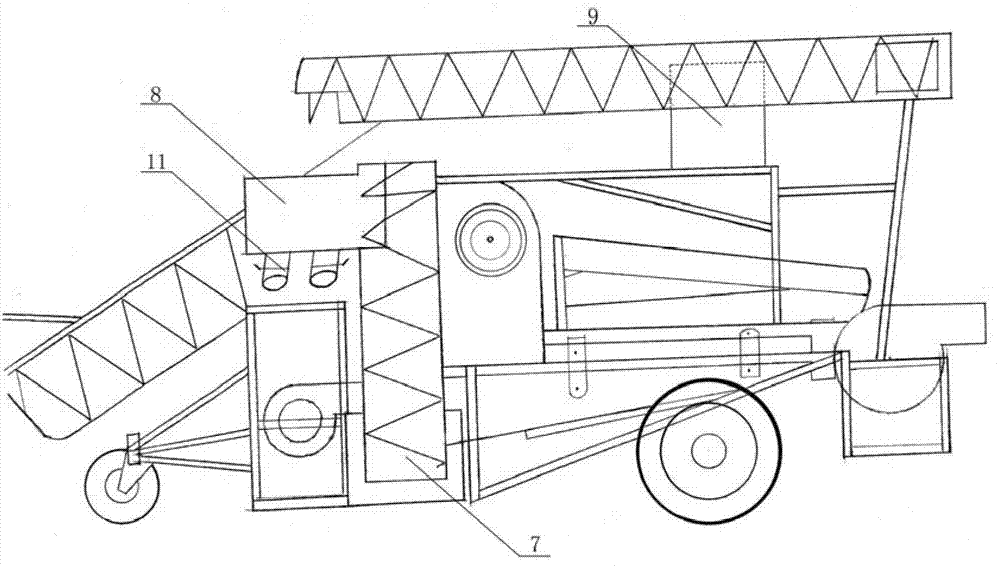

[0012] See figure 1 , figure 2 , image 3 , a blowing-suction dust-removing fork-type screening corn thresher, comprising a threshing host 5, a diesel engine 9, a feeding auger 7, a swinging screen 2, a blower 20, a lifting auger 7, and the thresher host 5 is fixed on a frame 1 , the threshing host 5 is double-roller 24 for threshing, adopts a multi-layer swinging screen 2, and is provided with a reciprocating slag screen 6 in front of the threshing host 5, and is provided with a three-layer swinging screen on the lower frame 1 of the thresher. The first layer is a fork screen 16, which is composed of multiple fork bars. The second layer is a large-hole screen 14, and the third layer is a small-hole screen 15, which are all fixed on the screen frame 13. The left end of the swing screen 2 is provided with a blower 20. , the right end is provided with a suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com