Double-drum threshing machine

A threshing machine and double-drum technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of high residue content in the extracted mixture, decreased threshing operation quality, and increased cleaning load, so as to reduce manual work The effect of strength, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

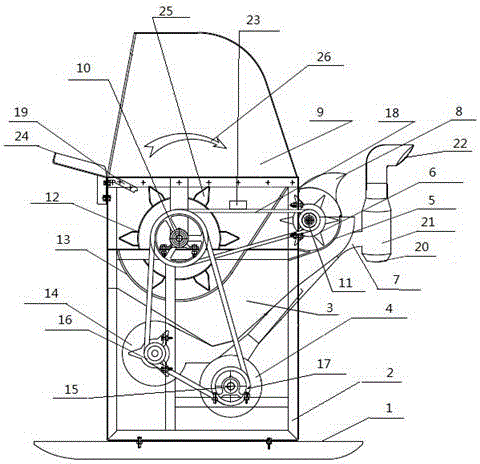

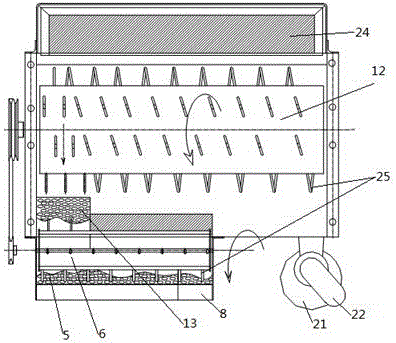

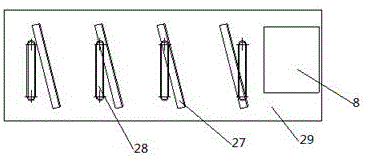

[0021] Such as figure 1 , figure 2 and image 3 As shown, a double-drum threshing machine of the present invention includes a power unit, a body, a primary threshing device, and a secondary threshing device. The secondary threshing device is composed of a secondary threshing drum 6, a secondary threshing sieve plate 5 and a body, the first threshing chamber is formed between the primary threshing drum 12, the primary threshing sieve plate 13 and the body, and the two A second threshing chamber is formed between the secondary threshing drum 6 , the secondary threshing sieve plate 5 and the body, and the first threshing chamber communicates with the second threshing chamber. This double-drum structure creatively solves the technical problem of only one threshing, and the threshing is not clean. After the rice is threshed by a threshing device, the removed rice grains fall into the barn 3 along the primary threshing sieve plate 13, and the threshing is not clean. The ears of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com