Rectangular lithium battery with improved packing structure

A packaging structure, lithium battery technology, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of cell shaking, pole piece staggering, and the force cannot be completely consistent, so as to improve safety performance and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

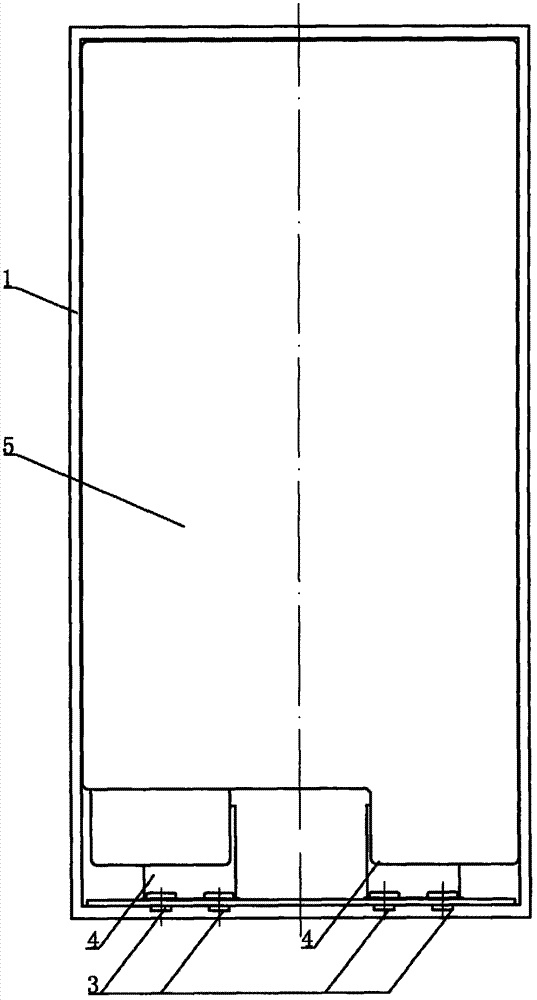

[0018] refer to figure 1 , the positive and negative electrical contacts 3 and the safety valve 4 are fixed on the reinforcing plate 7 at the end of the rectangular shell 1;

[0019] refer to figure 2 , the battery cell 5 is loaded into the wide opening of the rectangular shell 1; the coiled or laminated battery core 5 is placed parallel to the wide opening of the rectangular shell 1 into the shell, and one end of the electrical connecting piece 8 is connected to the electrical connection The contact 3 is connected, and one end is connected to the cell 5;

[0020] refer to image 3 , Figure 4 , the bottom of the shell 2 is in the direction of the wide mouth of one side perpendicular to the plane of the reinforcement plate 7 fixed on the end of the rectangular shell 1, and the four sides of the bottom of the shell 2 are welded and sealed with the wide mouth of the rectangular shell 1 around.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com