Searching methd and system for reasons of fault event in process industry

A fault event, search system technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as equipment operation failure, material composition index unqualified, production operation not meeting requirements, etc., to improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below in conjunction with the specific embodiments of the accompanying drawings.

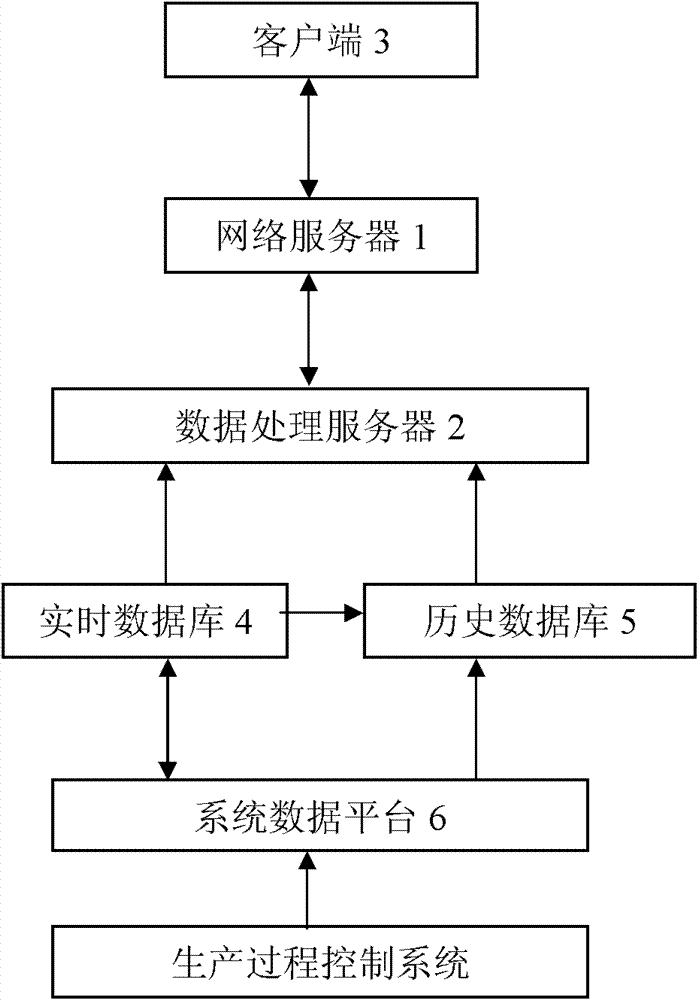

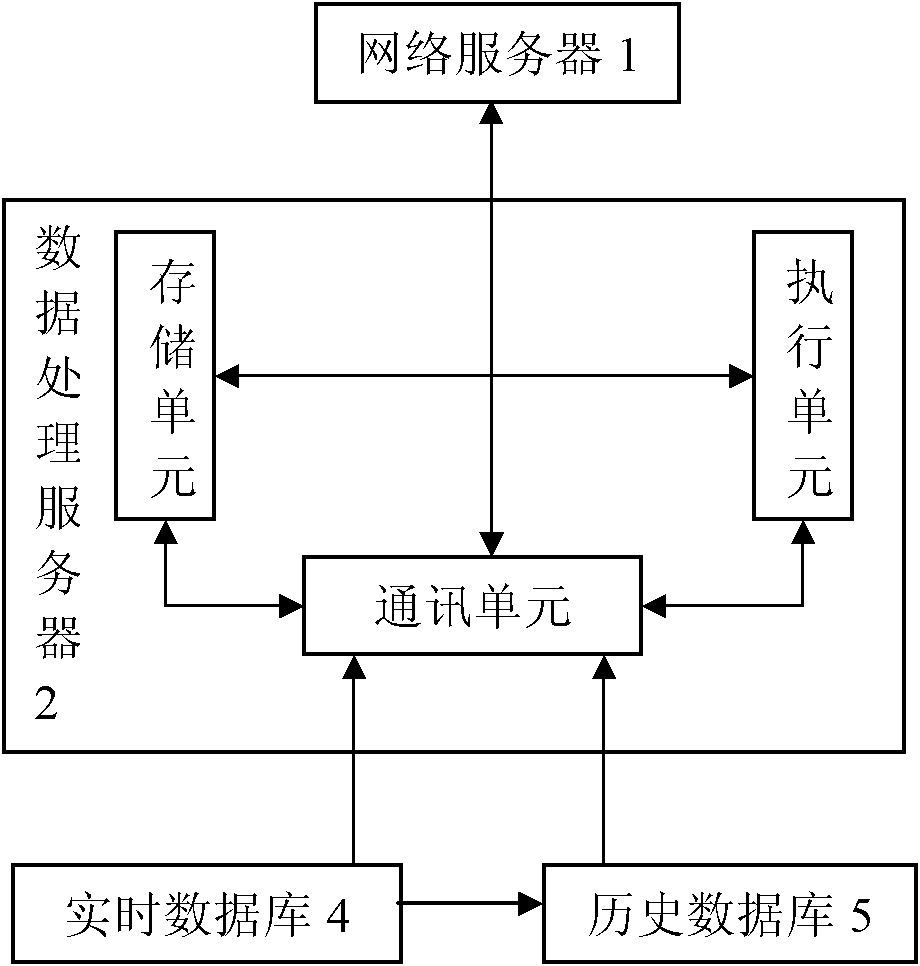

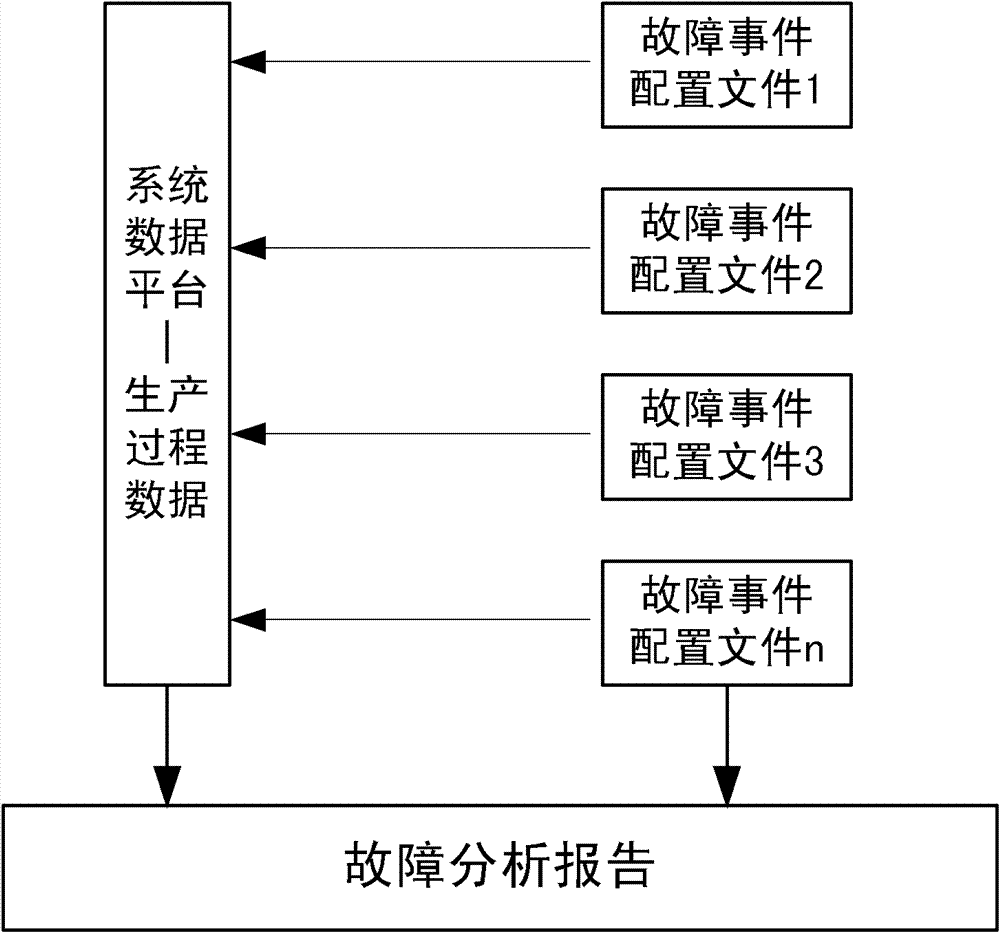

[0051] In order to automatically and efficiently find and search the root cause of failure events in the production process of products, a cause search system for process industry failure events has been established, such as Figure 1a As shown, it includes: a network server 1 , a data processing server 2 , a client 3 , a real-time database 4 , a historical database 5 , and a system data platform 6 . Any two or more of the above-mentioned various devices may be on the same computer, or may be different devices respectively.

[0052] System data platform 6 refers to the platform for obtaining on-site production process data. It can be connected with the on-site production process control system (such as DCS or PLC) through a communication network (such as industrial Ethernet). Its function is to collect and uniformly manage on-site production Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com