Testing device and evaluation method of antistrip performance of bituminous mixture

A technology of asphalt mixture and testing device, which is applied in the direction of measuring device, adopting mechanical device, analyzing materials, etc., to achieve the effect of good use effect, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

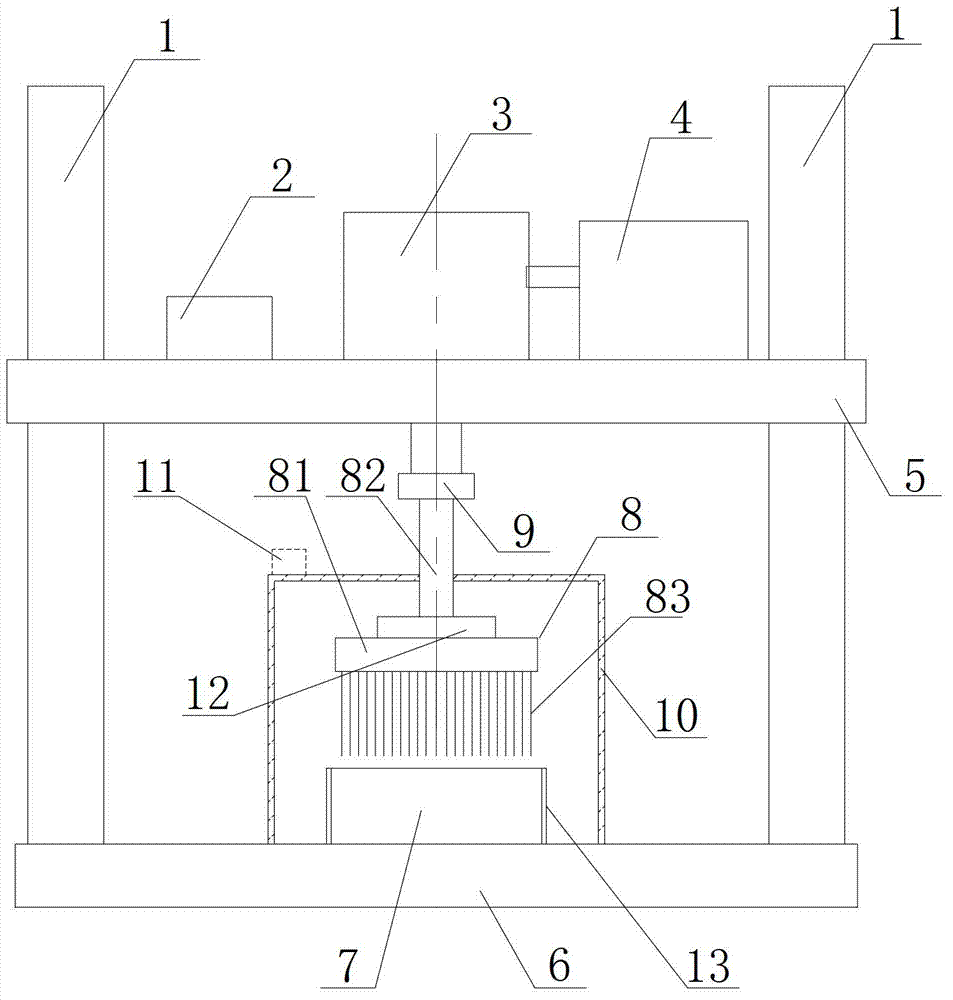

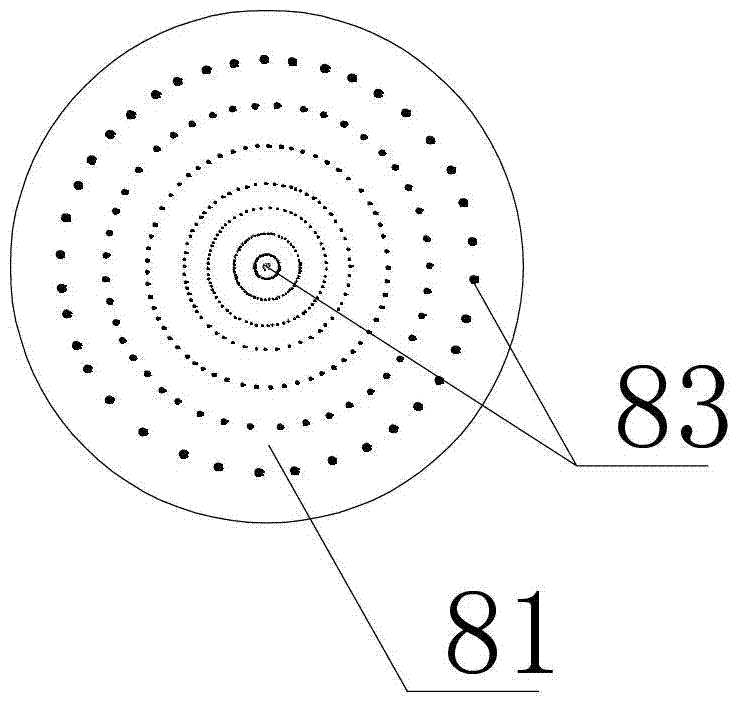

[0036] a kind of like figure 1 Shown is the anti-stripping performance test device of asphalt mixture of the present invention. The test device includes a base platform 6, a column 1 and a liftable platform 5. The column 1 is connected to the base platform 6. The liftable platform 5 is installed on the column 1. The lifting platform 5 is equipped with a reducer 3 connected to the motor 4. The reducer 3 is connected with the wire brush 8 located below the liftable platform 5 through a coupling 9. The densely distributed steel wires 83 on the wire brush 8 are facing the base platform 6. The set test piece placement groove 13.

[0037] In the test device of the present embodiment, the liftable platform 5 is equipped with a timer 2 capable of recording the scraping time between the wire brush 8 and the surface of the test piece 7 . A temperature control box 10 covering a wire brush 8 and a test piece placement groove 13 is installed on the base platform 6 , and a temperature cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com