Regenerative heat exchanger with forced rotor seal

A technology for regenerating heat exchangers and seals, which is applied in the direction of regenerative heat exchangers, indirect heat exchangers, and engine sealing, which can solve the problems of expensive and complicated sealing systems, and is beneficial to installation and reduces sealing gas The effect of high volume, simple operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

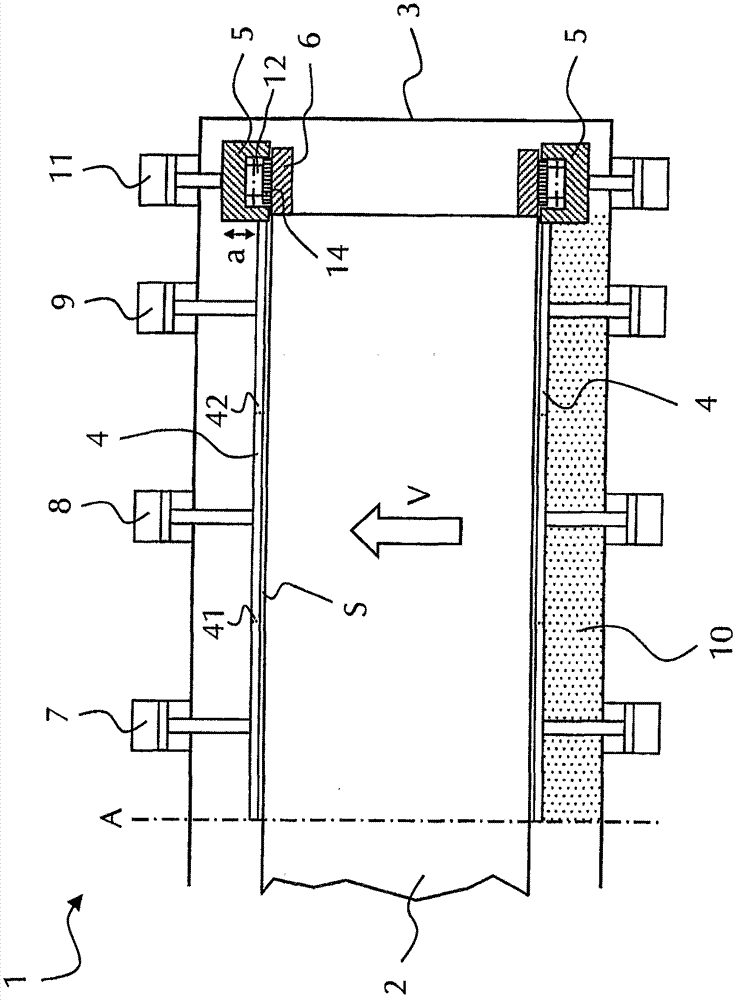

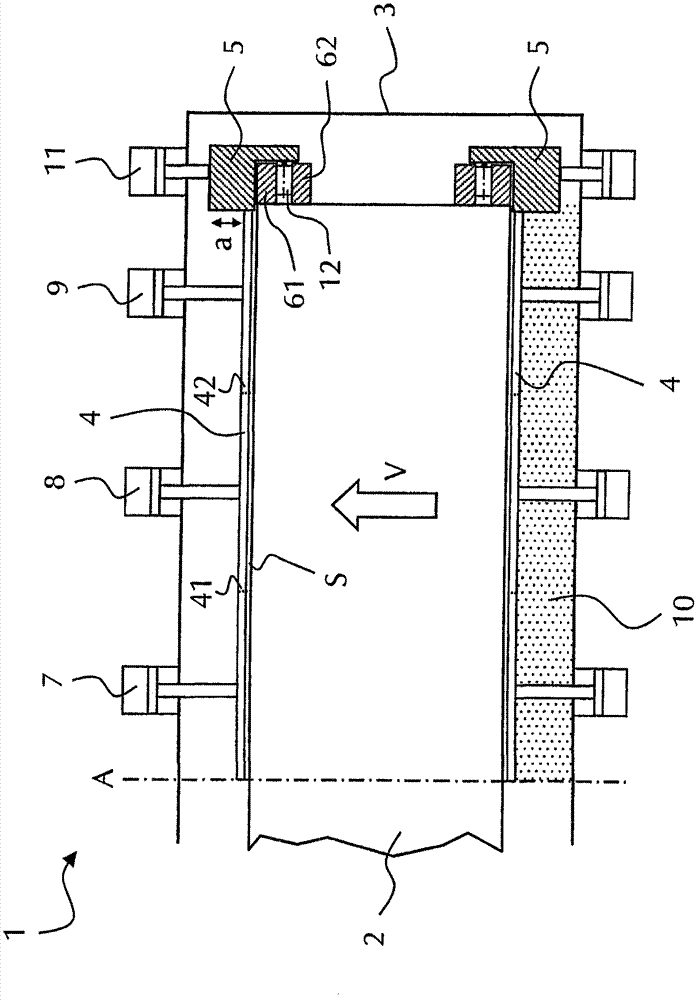

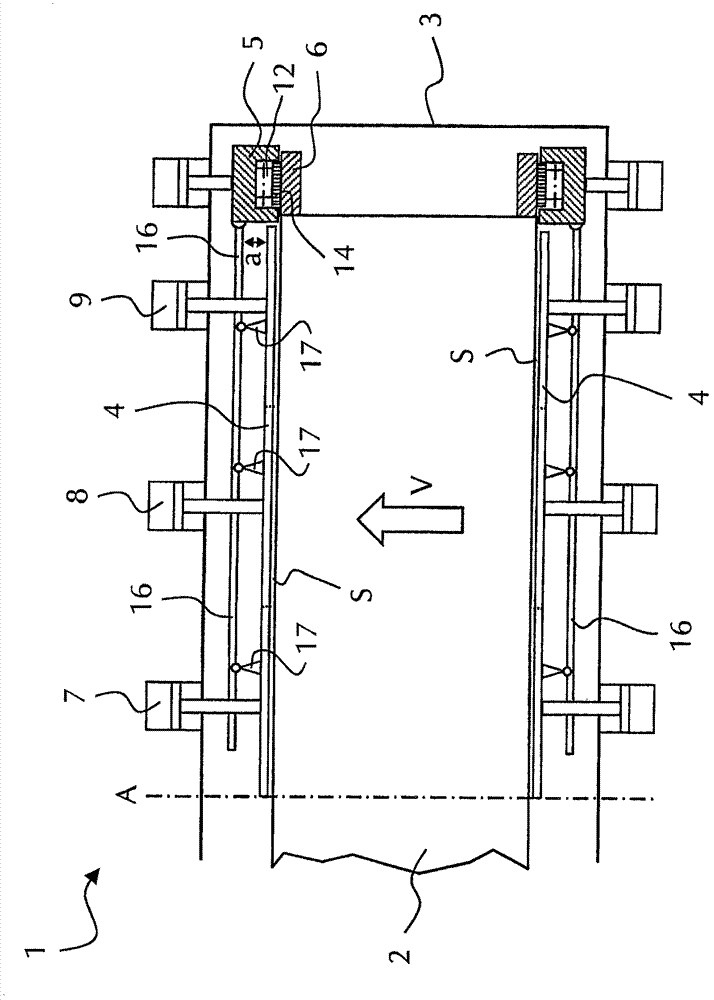

[0018] figure 1 A regenerative heat exchanger designated with reference number 1 is shown, of which only one half of the symmetrical structure is shown. The regenerative heat exchanger 1 comprises a rotor 2 which is held rotatably about a vertical axis of rotation A and is arranged in a rotor housing 3 . A plurality of gas volume flows V flow through the rotor 2 so that heat is transferred from at least one gas volume flow to at least another gas volume flow. A sealing system with a radial seal 4 and a circumferential seal 5 is provided for sealing the gas volume flow V guided through the regenerative heat exchanger 1 . The radial seal 4 is arranged on the front side of the rotor 2 and is provided for preventing a short-circuit volume flow between the gas volume flows V. FIG. The circumferential seal 5 is arranged on the face edge of the rotor 2 and is provided to prevent a leakage volume flow from entering the rotor housing 3 . The radial seal 4 and the circumferential sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com