Garbage incinerator body with secondary air inlet

A waste incinerator and air inlet technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of waste of heat energy, slag can not play a cooling role, etc., to achieve the effect of full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

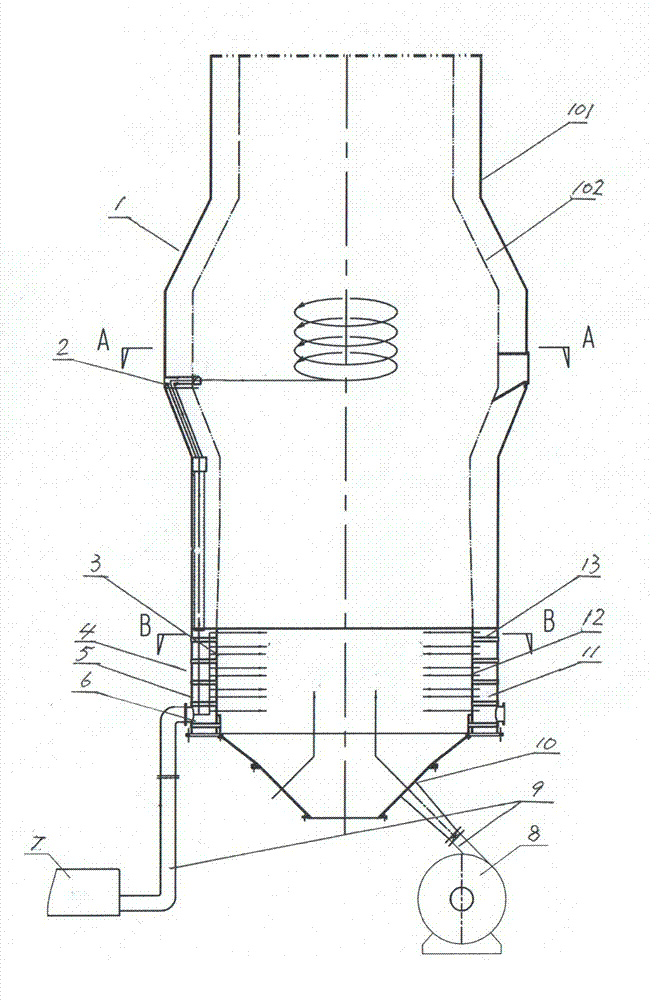

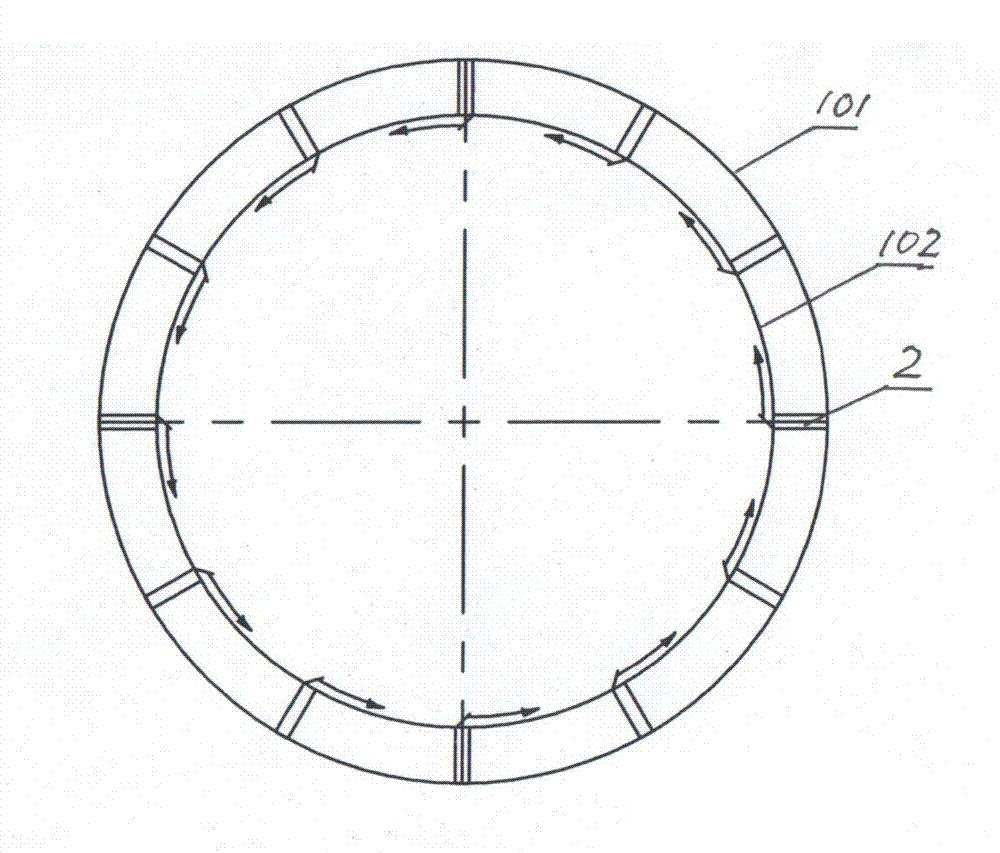

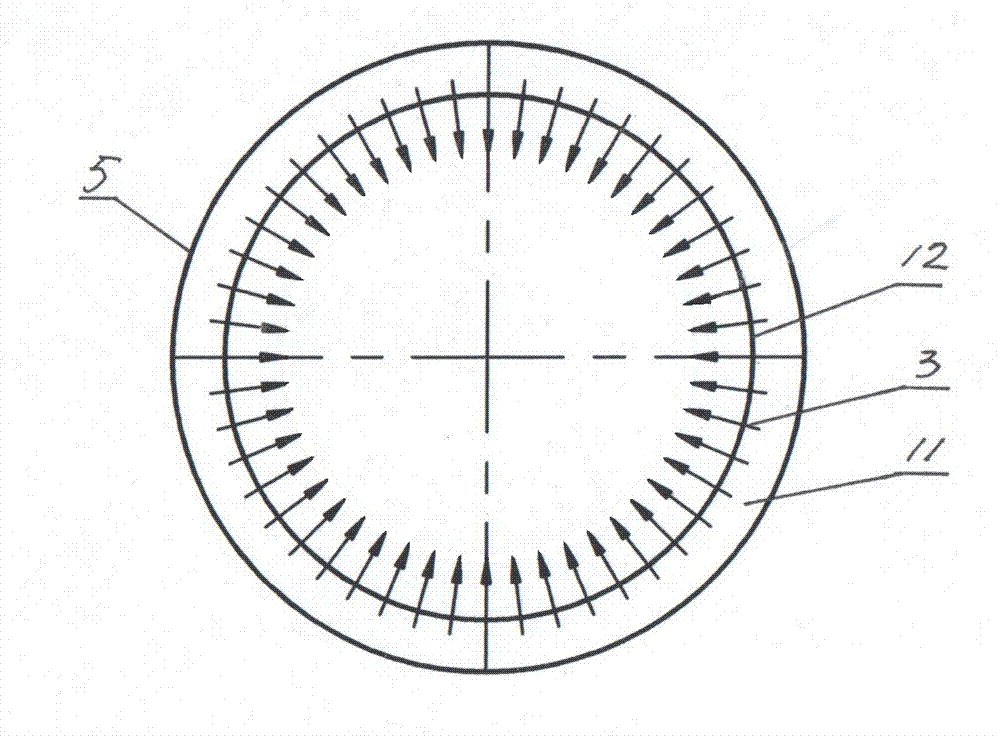

[0015] Such as figure 1 , figure 2 with image 3 As shown, the body of the garbage incinerator with the secondary air inlet of the present invention includes a furnace body, which is cylindrical and arranged vertically. The furnace body contains an upper furnace body 1 and a lower furnace body 4. The upper furnace body 1 is composed of a metal shell 101 and a refractory brick lining 102 inside the metal shell 101. The lower furnace body 4 contains a metal outer wall 5 and a metal In the inner wall 12 , there is a space between the metal outer wall 5 and the metal inner wall 12 for the air chamber 11 . The bottom of the lower furnace body 4 is processed with two primary air inlets 10. In the installed state, two first blowers 8 are installed under the furnace body corresponding to the two primary air inlets 10, and the air outlets of the two first blowers 8 Connect with two primary air inlets 10 respectively by means of pipeline 9, provide primary air for the furnace, to he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com