Exhaust gas condensate control method and exhaust gas recirculation system thereof

一种再循环系统、排放气体的技术,应用在废气再循环、电气控制、装料系统等方向,达到提高可用性和通用性、降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Reference will now be made in detail to various embodiments of the invention, examples of which are illustrated in the accompanying drawings and described below. While the invention will be described in conjunction with exemplary embodiments, it will be appreciated that present description is not intended to limit the invention to those exemplary embodiments. On the contrary, the invention is intended to cover not only the exemplary embodiments but also various alternatives, modifications, equivalents and others which may be included within the spirit and scope of the invention as defined by the appended claims. implementation.

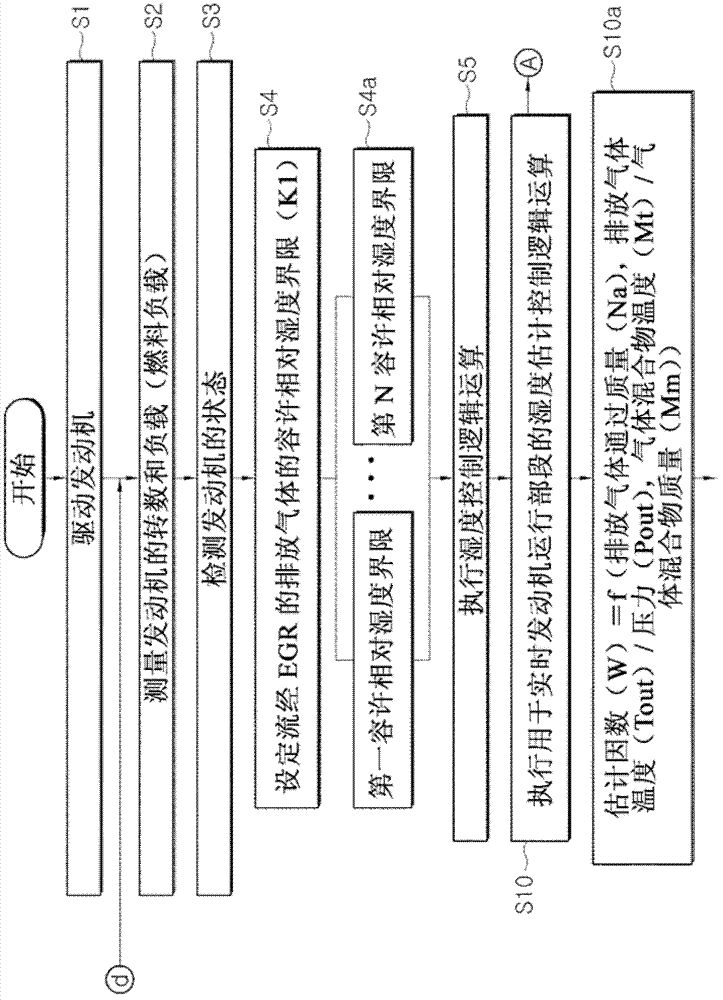

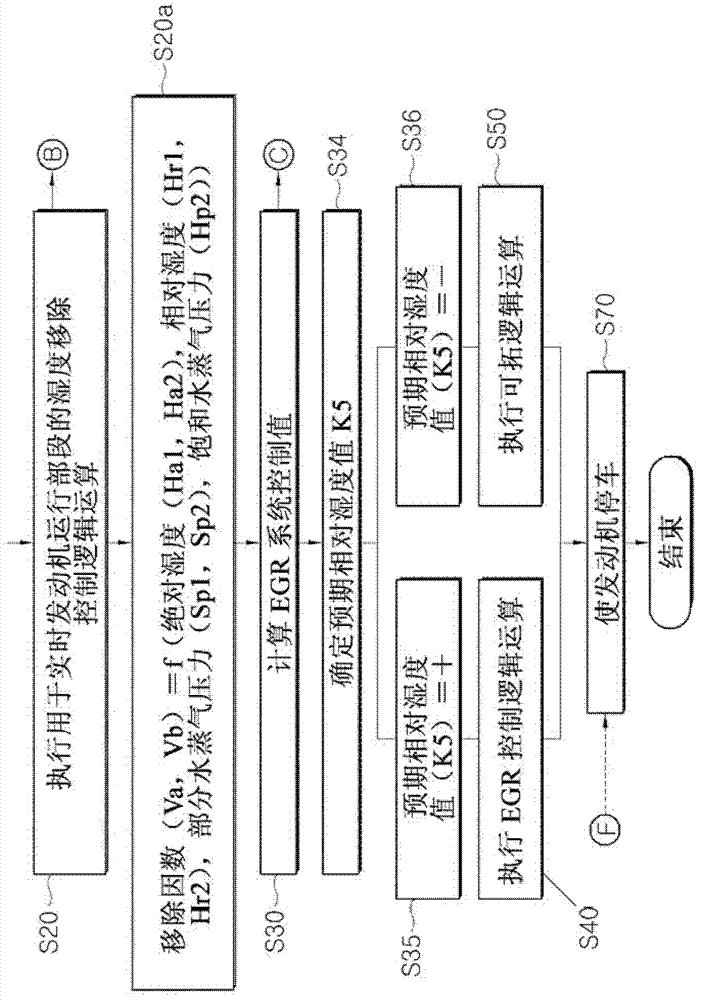

[0047] FIG. 1 , comprising FIG. 1(A) and FIG. 1(B), is a flow chart showing an exemplary method for treating condensate from exhaust gas flowing through an exhaust gas recirculation (EGR) system according to the present invention. Take control.

[0048] As shown in Figure 1, when the engine is started in step S1, the revolutions per minute (R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com