Delay coking coke cooling water demulsifier composition and preparation method and application thereof

A technology of delayed coking and demulsifier, applied in the field of demulsifier of chemical auxiliary demulsifier and demulsifier composition of oily sewage, which can solve heat waste, increase equipment pressure drop and equipment investment, hot water lift pump, degreaser clogging, etc. problem, to achieve the effect of convenient filling and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

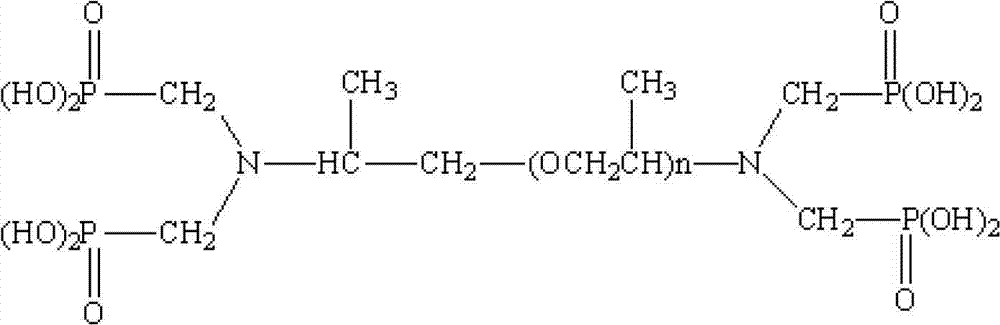

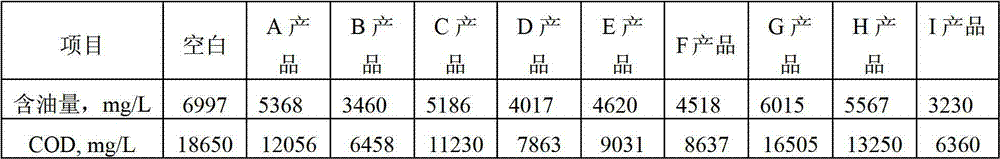

[0026] A preparation method of a demulsifier composition, comprising the steps of: mixing 160g polyethylene polyamine propylene polyoxypropylene ether (16%), 200g sodium hexametaphosphate (20%), 140g propylene glycol polyoxypropylene polyoxyethylene block Polyether (14%), 120g sodium ethylenediaminetetramethylene phosphonate (12%), and 380g deionized water (38%) were added to a container, stirred and mixed evenly, cooled to room temperature, and filtered to obtain a demulsifier composition A product.

Embodiment 2

[0028] A preparation method of a demulsifier composition, comprising the steps of: mixing 250g alkylphenol formaldehyde resin polyoxyethylene polyoxypropylene ether (25%), 200g trisodium phosphate (20%), 250g propylene glycol polyoxypropylene polyoxyethylene Block polyether (25%), 200g sodium ethylenediamine tetramethylene phosphonate (20%), 100g deionized water (10%), add to the container, stir and mix evenly, cool to room temperature, filter to obtain demulsifier Composition B product.

Embodiment 3

[0030] A preparation method of a demulsifier composition, comprising the following steps: 120g of alkylphenol formaldehyde resin polyoxyethylene polyoxypropylene ether (12%), 200g of polyaspartic acid (sodium) (20%), 120g of Pingpingjia O-15 (12%), 110g hydroxyethylidene diphosphoric acid (11%), 450g deionized water (45%), add to the container and heat, stir and mix well, cool to room temperature, filter to obtain demulsifier composition C product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com