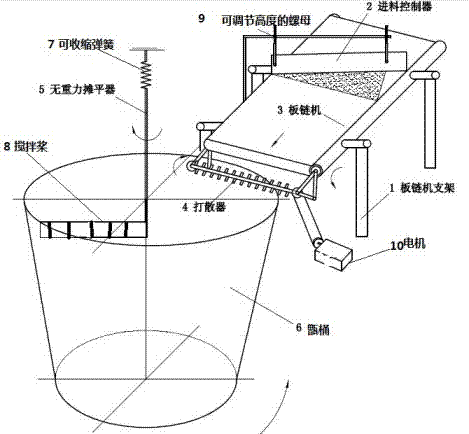

Method and device for automatically and uniformly loading materials into white spirit steaming barrel

A technology for retort barrels and liquor, which is applied in the field of automatic and even retort retorts for liquor retorts, mechanical equipment and devices, which can solve problems such as the inability to ensure the dispersion and uniformity of distiller's grains, achieve uniform retort, ensure uniformity and porosity, and be easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will illustrate one of the most preferred upper steamer device and upper steamer method of the present invention in conjunction with the accompanying drawings. It should be noted that the realization of the present invention is not limited to this specific embodiment, and any other alternative means and modes can be used , and within the protection scope of the present invention.

[0034] After the fermentation of the liquor is completed, the fermented grains are input from the plate chain machine 3 (feeding device), and the height-adjustable nut 9 is adjusted to make the distance between the scraper 2 (feeding controller) and the plate chain machine form different ends. angle. This ensures that there is less material to be blanked at the central position of the retort bucket 6, and more material is blanked at the edge position, so that the material on the plate chain machine 3 is thicker on the outside and thinner on the inside when the material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com