Ni-plated steel sheet with excellent pressability for battery can

A technology of battery cans and steel plates, applied in battery pack parts, battery boxes/jackets, battery box/cover materials, etc., can solve the problem of less frequent replacement of pressurized molds, and achieve the effect of inhibiting wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

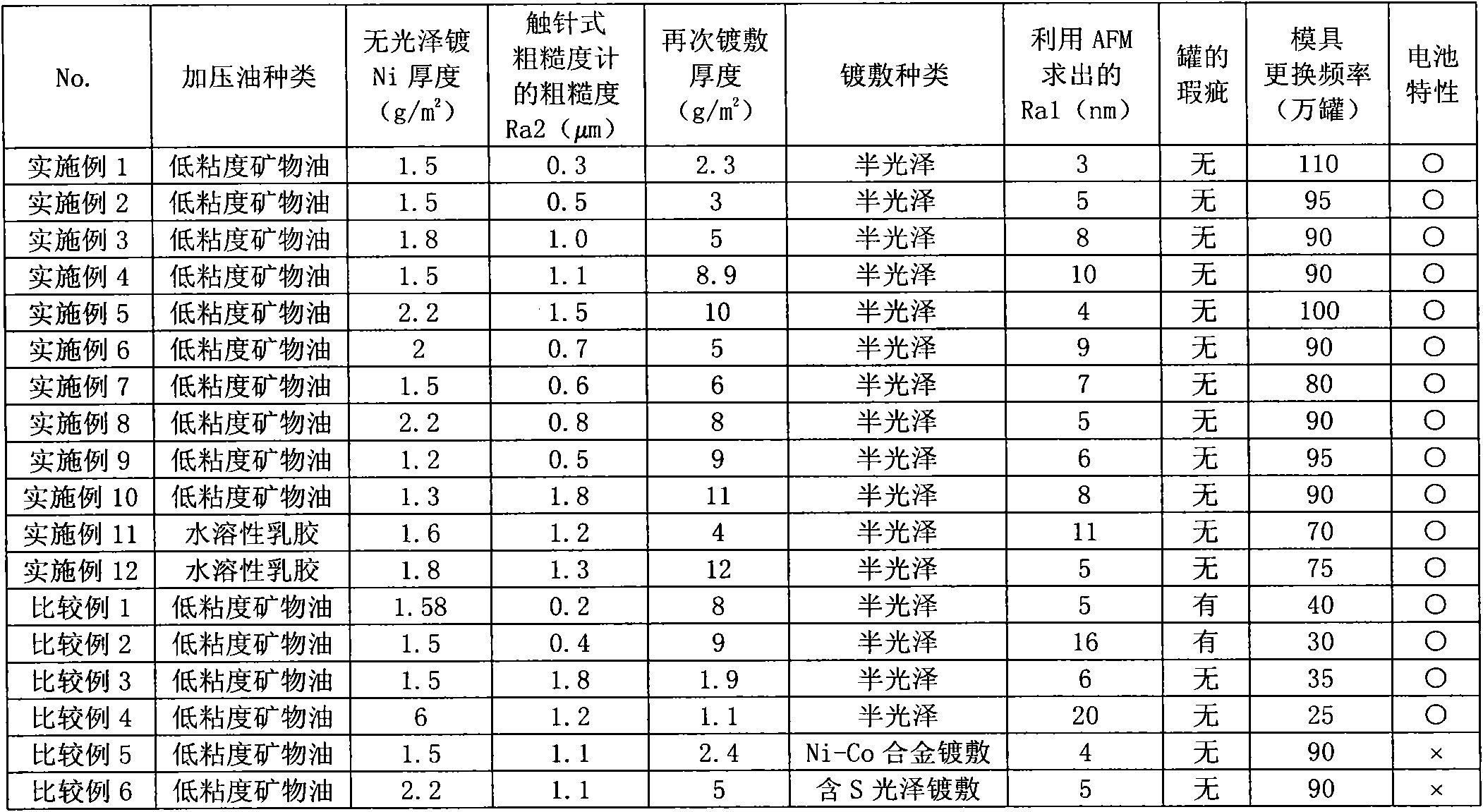

[0120] A steel plate having a plate thickness of 0.25 mm after cold-rolling with a low-carbon aluminum-killed hot-rolled coil and annealing was used. On the steel plate, the surface to be the outer surface of the battery can is plated with a thickness of 1.5g / m 2 Matte Ni plating.

[0121] In addition, 10g / m is applied to the surface that becomes the inner surface of the battery can 2 Matte Ni plating. After Ni plating, carry out continuous annealing at 700°C for 30 seconds to diffuse the Ni plating to form a Fe-Ni diffusion layer and a soft Ni layer thereon.

[0122] In addition, the Ni deposition amount of the Fe-Ni diffusion layer and the Ni layer thereon can be considered to be almost the same value as the deposition amount of the matte Ni plating layer before the diffusion treatment.

[0123] After the diffusion treatment, temper rolling was carried out so that the surface roughness Ra 2 obtained by a stylus type roughness measuring device became 0.3 μm with respect to...

Embodiment 2~12

[0128] In the same manner as in Example 1, Ni-plated steel sheets for battery cans of Examples 2 to 12 were formed.

[0129] However, in Examples 2 to 12, the matte Ni plating applied to the surface to be the outer surface of the battery can, and the surface to be the outer surface of the can formed by temper rolling were determined by a stylus type roughness measuring instrument. The surface roughness Ra2, the thickness of replating applied to the soft Ni layer, and the surface roughness Ra1 obtained by atomic force microscopy (AFM) after semi-bright Ni plating varied as shown in Table 2, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com