Method for correcting flue wall of roasting furnace

A flue wall and roasting furnace technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of rising costs, increasing difficulty in temperature control, and high costs, so as to reduce maintenance costs and increase furnace loading output , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

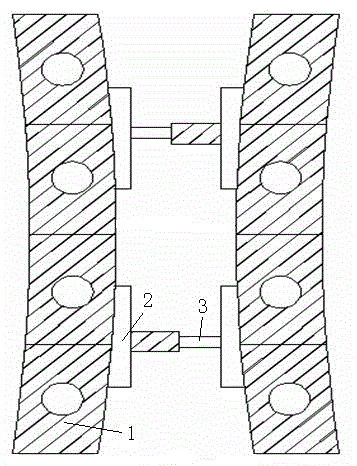

[0014] A material box with a depth of 5496mm, a width of 710mm and a length of 5298mm in the roasting furnace was deformed due to the "overburning" of the flue wall 1, and the middle width changed from the designed 710mm to 650mm, making some varieties unable to be loaded into the furnace. Use this technology to correct the material box. When producing pre-baked anodes with a length of 1513mm, a height of 554mm, and a width of 670mm, the first layer of pre-baked anodes should be installed first, and wooden sleepers and jacks should be set up at the 1750mm position of the flue wall. For the first correction, after the pressure is applied for 6 hours, tamp the filling material of the material box, remove the jack, and then install the second layer of prebaked anodes, and then carry out repeated corrections. When the correction requirements are met, this can be completed. item of work.

[0015] It should be noted that the flue wall cannot be too damaged, the refractory brick must...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com