Riddling machine system

A bottle-rotating and ground-rotating technology, which is applied in the field of winemaking, sparkling wine, especially the riddling stage of champagne manufacturing, which can solve the problems of high manufacturing cost and increased overall cost of champagne

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] While the invention is capable of embodiments in different forms, as shown in the drawings, and specific embodiments of the invention will be described herein in detail, it is considered that the description herein is considered as illustrative of the principles of the invention and is not intended to Limit the invention to what is described and illustrated herein.

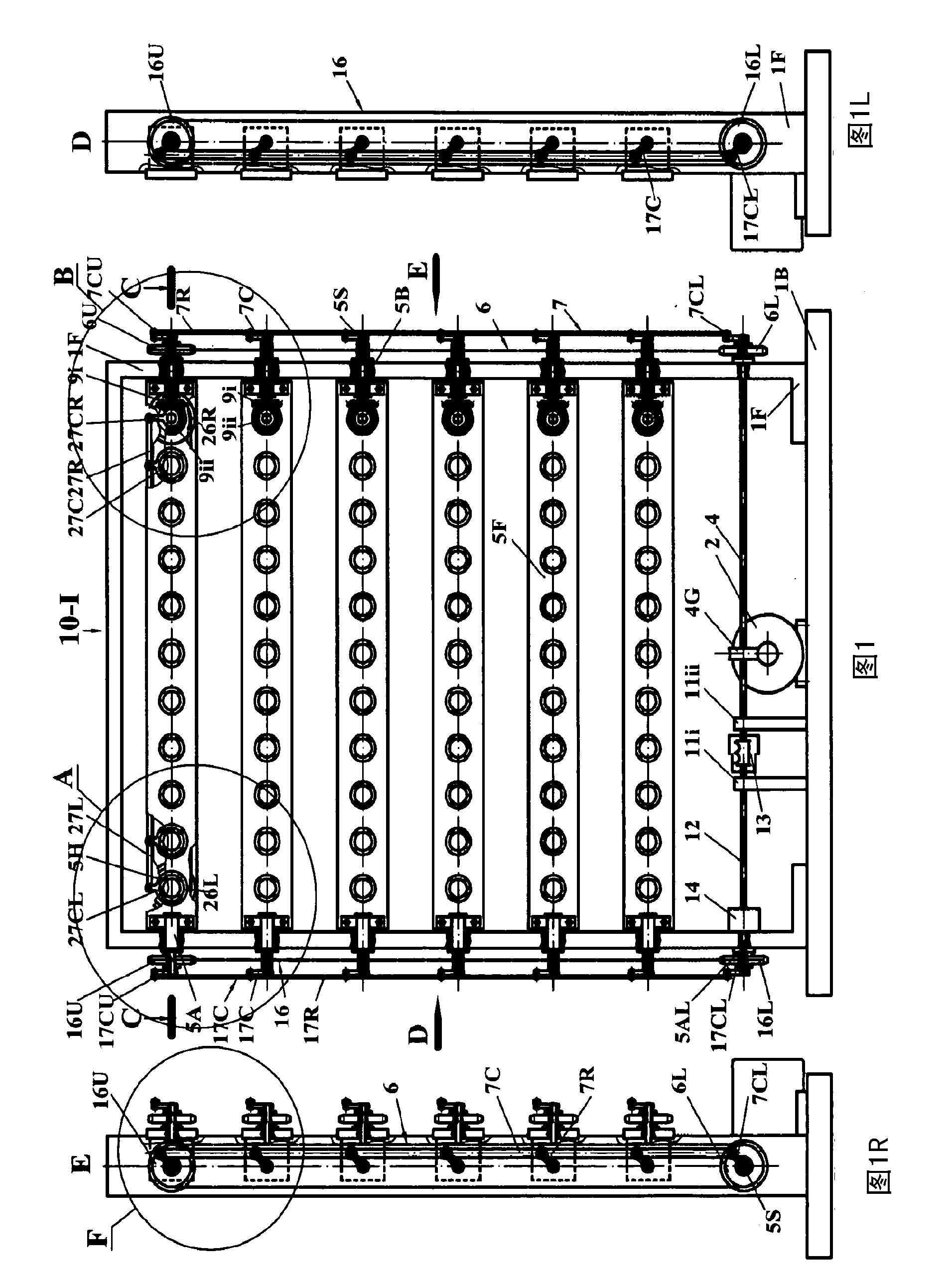

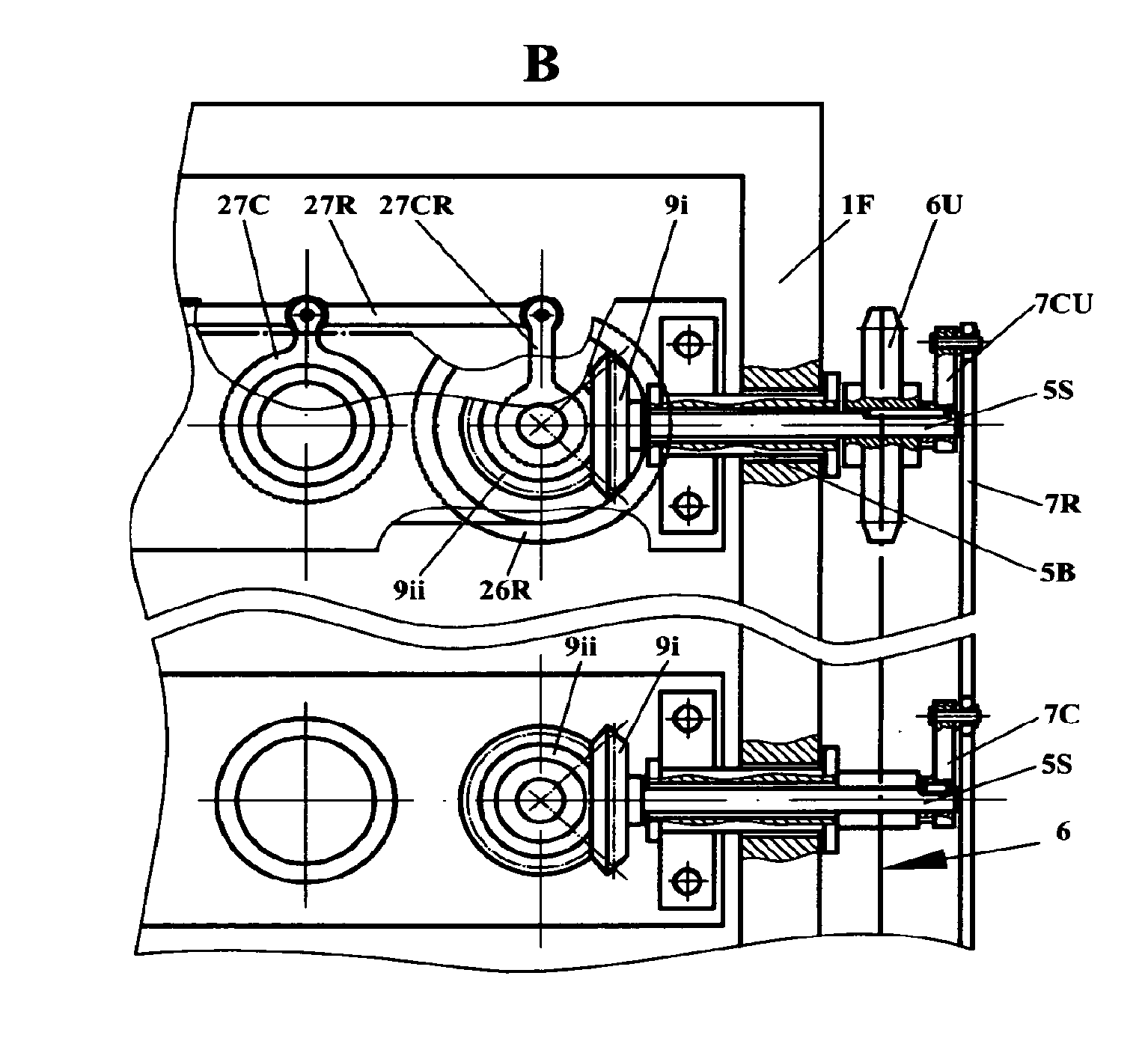

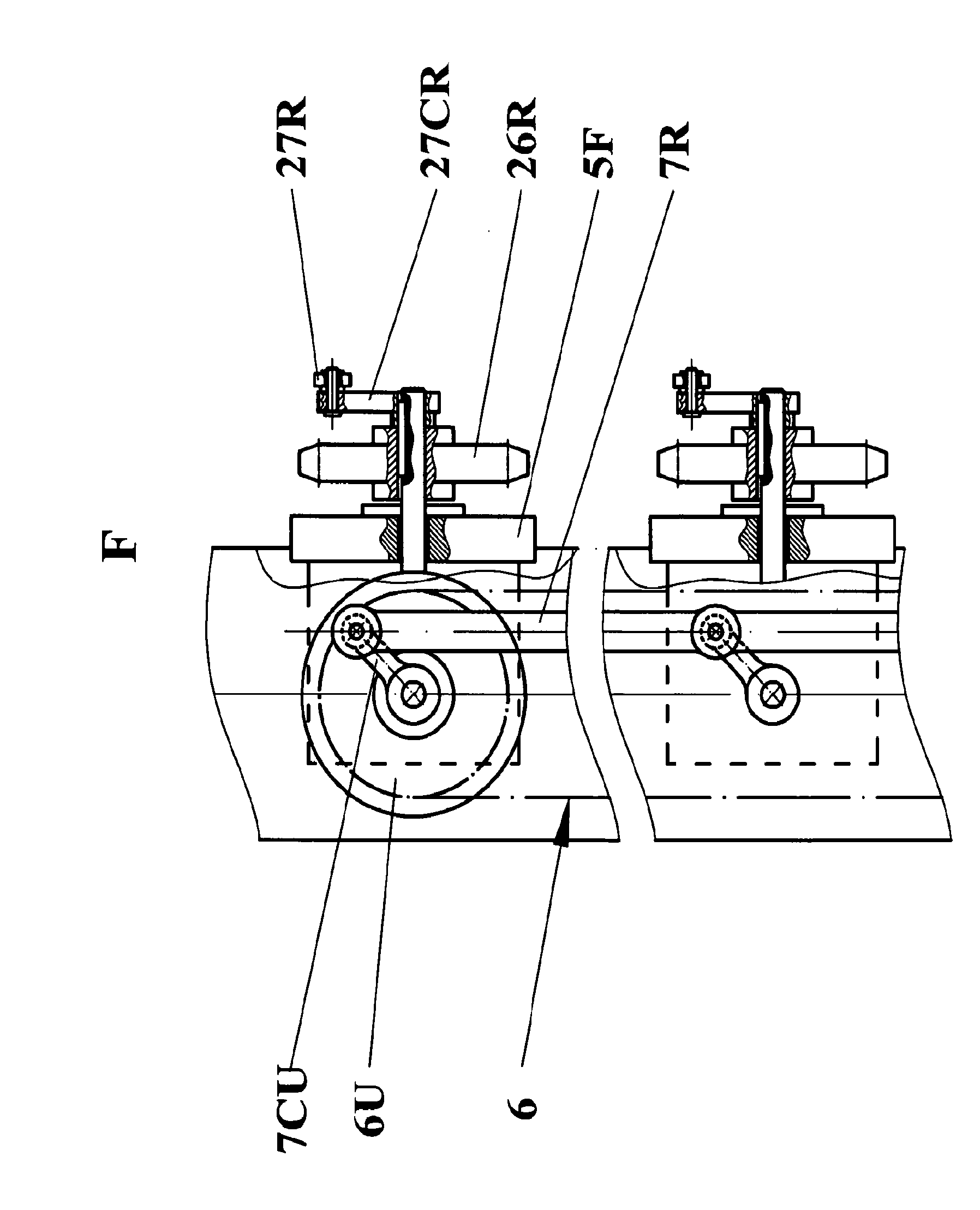

[0021] "Chain-Chain" Form

[0022] Champagne machines in the form of "chain-to-chain" (such as figure 1 shown) includes at least one main device (10-I), which includes:

[0023] a base (1B), which is preferably arranged horizontally;

[0024] a support frame (1F), preferably arranged vertically and fixedly mounted on the base 1B;

[0025] The main motor (2), the main motor is preferably installed on the base 1B, in a preferred embodiment, the main motor is made of variable speed motor;

[0026] Common main shaft (4), said shaft is preferably arranged horizontally and is rotatably mounted, the first end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com