Simple human assisted reprocessing wire separating device

A technology of artificial assistance and wire splitting device, which is applied in the direction of recycling technology, electrical components, circuits, etc., can solve the problems of unsuitable cable cores, large equipment investment, easy loss of cable cores, etc., and achieve the goal of reducing costs and capital pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

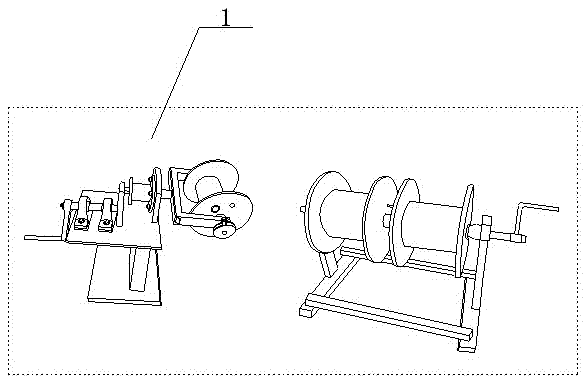

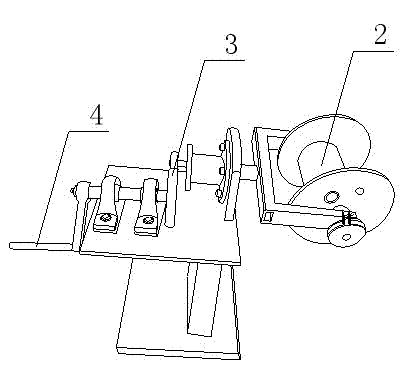

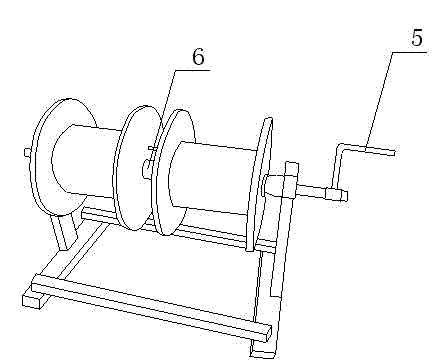

[0013] Such as figure 1 , figure 2 with image 3 As shown, a simple manual assisted rework branching device of the present invention, a simple manual assisted rework branching device, includes a whole set of simple manual assisted thread branching device 1, a whole set of simple manual assisted thread branching device 1 Includes pay-off device (see figure 2 ) and take-up device (see image 3 ), pay-off device (see figure 2 ) is provided with a pay-off bracket 2, the pay-off bracket 2 is connected with the mechanical transmission gear 3, the mechanical transmission gear 3 is connected with the pay-off handle 4, and the take-up device (see image 3 ) includes a take-up bracket 5, and a take-up handle 6 is provided on the take-up bracket 5.

[0014] In a simple manual assisted rework branching device of the present invention, pour the reworked core into the wire reel and install it on the pay-off bracket 2, and manually turn the pay-off handle 4 through the mechanical tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com