Method for preparing photoelectric composite submarine cable

A submarine cable, optoelectronic composite technology, applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problems of cable mechanical performance decline, poor aluminum waterproof effect, unable to guarantee the service life of submarine cables, etc. Guarantees the effect of water blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

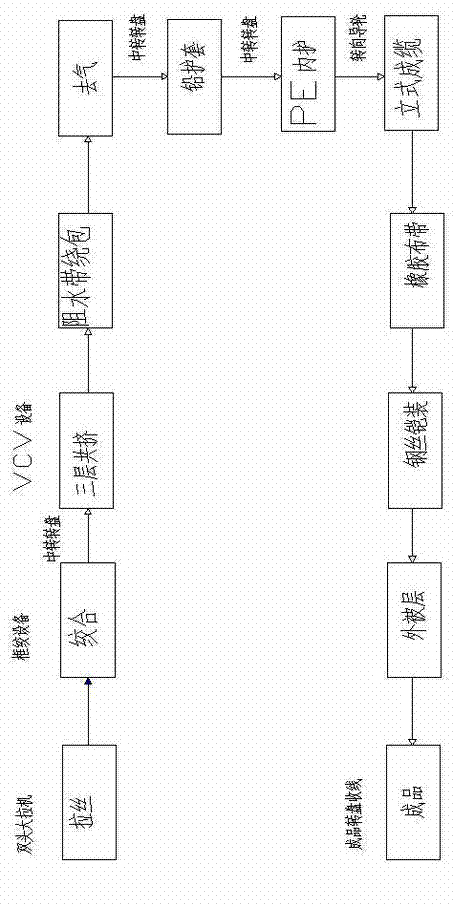

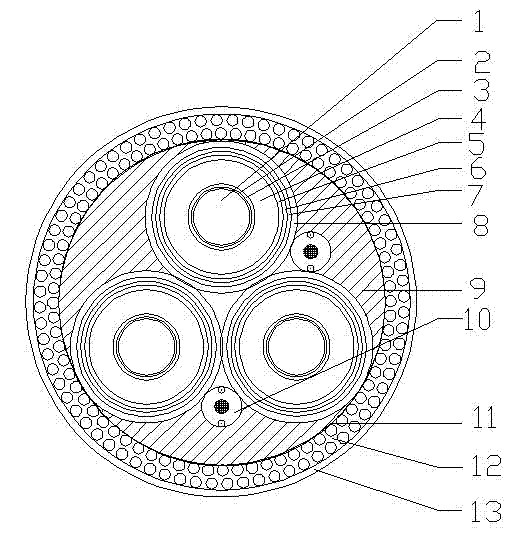

[0045] A method for preparing a photoelectric composite submarine cable, characterized in that the following steps are adopted:

[0046] A), wire drawing treatment is carried out to the conductor;

[0047] B), utilize 91 coil frame winches to manufacture the conductor obtained in step 1 into three sections with a cross-sectional area of 630mm 2 round conductors;

[0048] C), the outer layers of the three circular conductors obtained in step B) are all wrapped with semi-conductive tape, and then the wires are respectively taken up to the 10m diameter transfer turntable through the steering guide wheel;

[0049] D) Pass the conductors on the three 10m-diameter transfer turntables through the vertical cross-linking production line VCV respectively to perform conductor shielding, insulation and insulation shielding co-extrusion processes, and perform water-blocking tape at the outlet of the vertical cross-linking production line VCV Spiral wrapping;

[0050] E), then the thre...

Embodiment 2

[0060] A method for preparing a photoelectric composite submarine cable, characterized in that the following steps are adopted:

[0061] A), wire drawing treatment is carried out to the conductor;

[0062] B), utilize 91 coil frame winches to manufacture the conductor obtained in step 1 into three sections with a cross-sectional area of 630mm 2 round conductors;

[0063] C), the outer layers of the three circular conductors obtained in step B) are all wrapped with semi-conductive tape, and then the wires are respectively taken up to the 10m diameter transfer turntable through the steering guide wheel;

[0064] D) Pass the conductors on the three 10m-diameter transfer turntables through the vertical cross-linking production line VCV respectively to perform conductor shielding, insulation and insulation shielding co-extrusion processes, and perform water-blocking tape at the outlet of the vertical cross-linking production line VCV Spiral wrapping;

[0065] E), then the thre...

Embodiment 3

[0075] A method for preparing a photoelectric composite submarine cable, characterized in that the following steps are adopted:

[0076] A), wire drawing treatment is carried out to the conductor;

[0077] B), utilize 91 coil frame winches to manufacture the conductor obtained in step 1 into three sections with a cross-sectional area of 630mm 2 round conductors;

[0078] C), the outer layers of the three circular conductors obtained in step B) are all wrapped with semi-conductive tape, and then the wires are respectively taken up to the 10m diameter transfer turntable through the steering guide wheel;

[0079] D) Pass the conductors on the three 10m-diameter transfer turntables through the vertical cross-linking production line VCV respectively to perform conductor shielding, insulation and insulation shielding co-extrusion processes, and perform water-blocking tape at the outlet of the vertical cross-linking production line VCV Spiral wrapping;

[0080] E), then the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com