Improved rubber roll device and manufacturing method thereof

A manufacturing method and technology for rubber rollers, which can be applied to hoisting devices, portable lifting devices, components with teeth, etc., and can solve the problems of short service life and easy slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable the examiner to have a more detailed and clear understanding of the present invention, the preferred embodiments of the present invention are described in detail below in conjunction with the drawings. These descriptions are only used to illustrate the present invention, not to make any statement on the scope of rights of the present invention. limit.

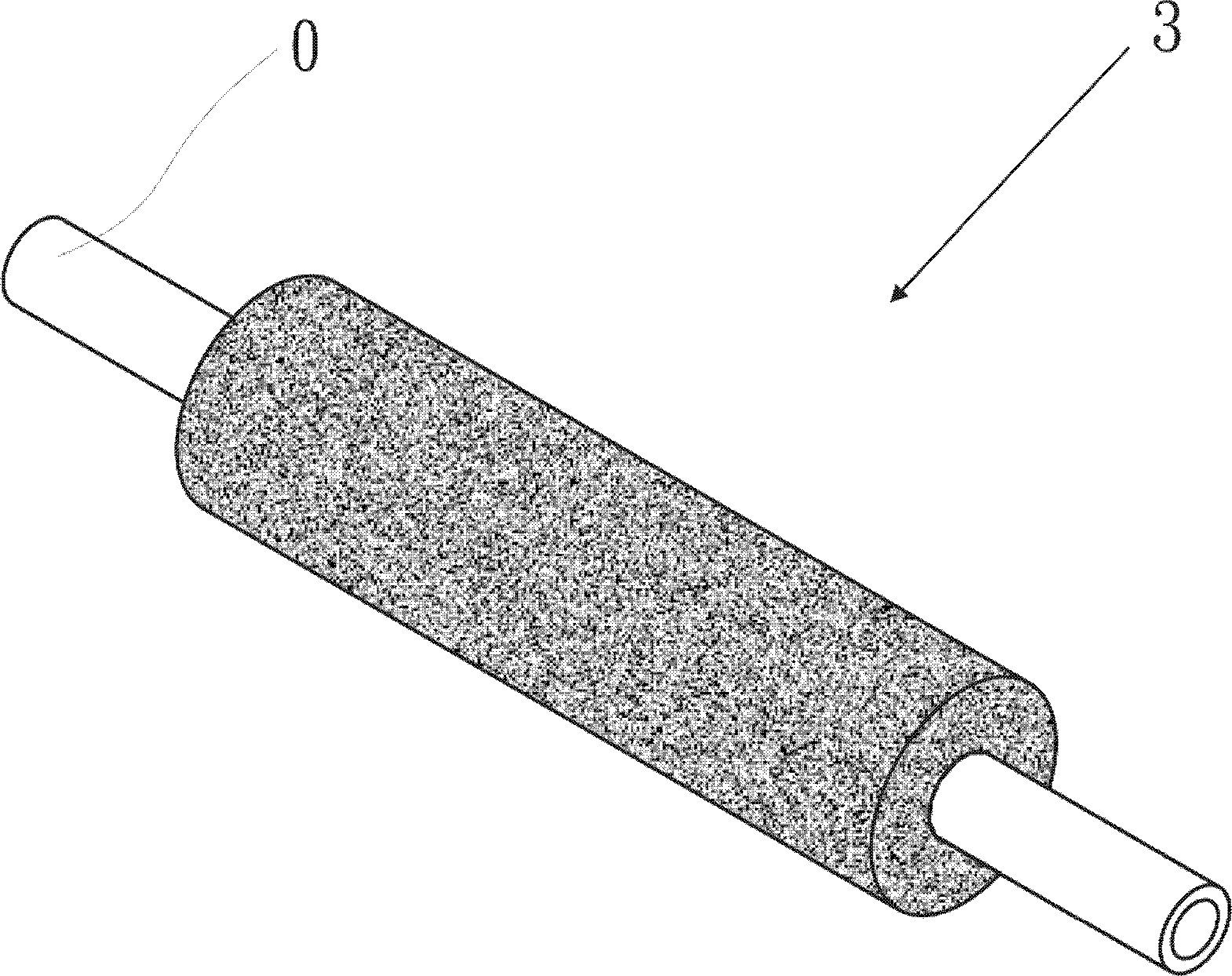

[0038] Please check image 3 , it is the improved rubber roller device 3 of the present invention, its material is selected as PU, and the micro air holes 31 are formed in the inside which are roughly uniform and densely distributed, so that the physical structure of the rubber roller 3 is a non-slip rough surface with toughness from the inside to the outside , that is, no matter what diameter the rubber roller 3 is worn to, its outer surface is a non-slip rough surface with friction.

[0039] see Figure 4 , which is the implementation process of the above-mentioned improved rubber roller device 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com