Assembling structure of suspended ceiling

A technology for assembling structures and ceilings, applied in the field of architectural decoration, can solve the problems of cluttered ceilings, inconvenient installation, disassembly or replacement, etc., and achieve the effects of simple component structure, low cost, and clean structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

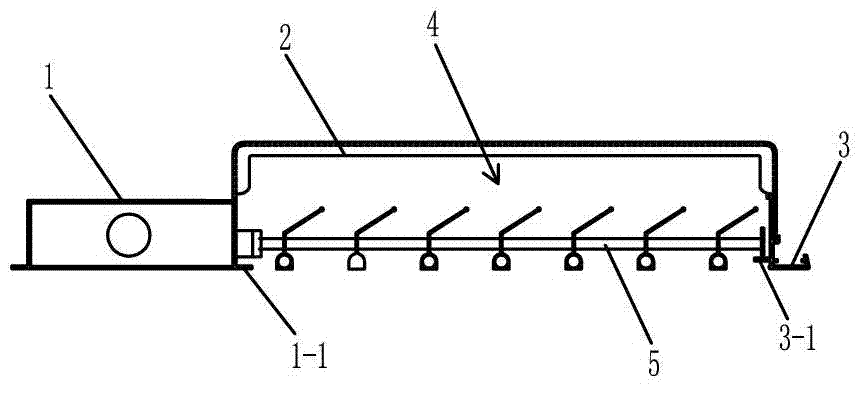

[0046] Embodiment one: see figure 1 , 2 The assembly structure of the suspended ceiling in this embodiment includes a light frame 1, a connecting frame 2, and a side plate 3. The light frame 1 is equipped with a luminous body, and the lower opening of the light frame can be equipped with a light-transmitting plate or a light-transmitting cover. Pass through the light-transmitting plate or light-transmitting cover of the light frame to illuminate the outside. The light frame 1 and the side plate 3 are arranged in parallel with a distance, and the two are fixedly connected by the connecting frame 2 . Thus, a functional space 4 is formed between the lamp holder 1 and the side plate 3, and various functional equipment terminals can be placed in this functional space. There is a grid plate 5, which has a decorative effect and a tuyere diversion effect. In this embodiment, the lamp holder 1 and the side plate 3 respectively form a shelf 1-1 and 3-1 facing opposite sides, and a gr...

Embodiment 2

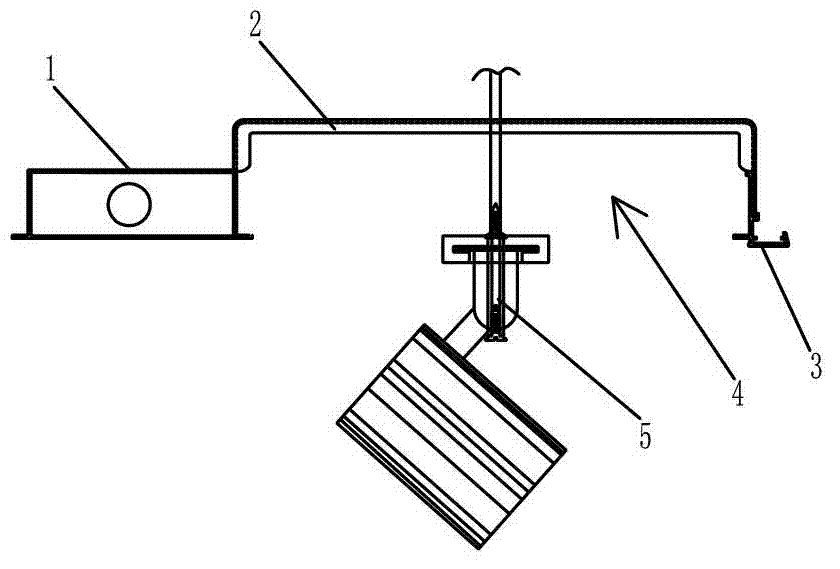

[0047] Embodiment two: see image 3 , 4 , in this embodiment, the functional equipment terminal is the guide rail spotlight 5, and the guide rail spotlight 5 is fixed on the top surface of the building ceiling.

[0048] There is no grid plate in this embodiment, and the other contents are the same as in the first embodiment, refer to the first embodiment.

Embodiment 3

[0049] Embodiment three: see Figure 5 , the assembly structure of the suspended ceiling in this embodiment includes a light frame 1, a connecting frame 2, and a light frame 3. Light-emitting bodies are installed in the two light frames. The lower opening of the light frame can be equipped with a light-transmitting plate or a light-transmitting cover. The light shines to the outside through the light-transmitting panels or light-transmitting covers of the respective lamp stands. The two light frames are arranged in parallel with a distance between them, and the two are fixedly connected by the connecting frame 2 . Thus, a functional space 4 is formed between the two lamp holders, and various functional equipment terminals can be placed in this functional space. In this embodiment, the functional device terminal is a point light source 5 installed on the connecting frame 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com