Continuous annealing production method for steel for 280 MPa vehicle structure

A technology of automobile structure and production method, which is applied in the field of metallurgical plate production, can solve the problems of high Mn alloy price, high production cost, and high equipment requirements, and achieve the effect of increasing C content, low cost, and good matching of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below through embodiment.

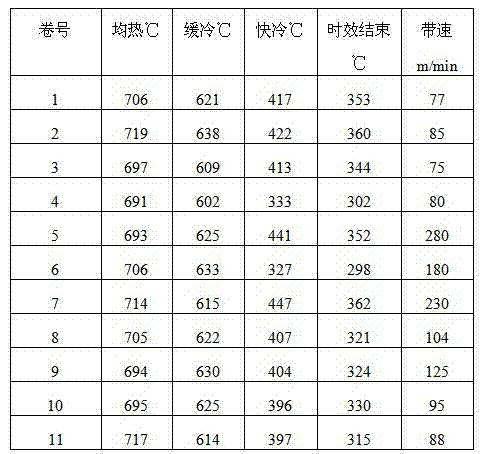

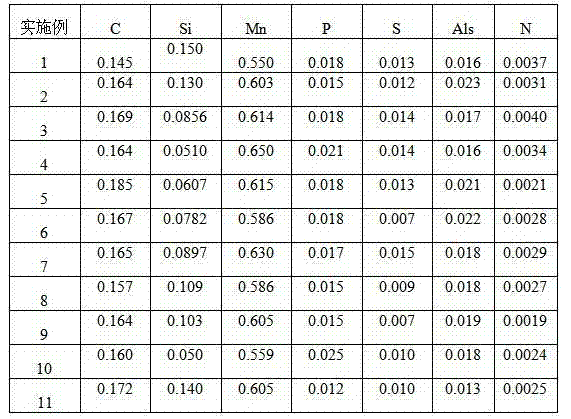

[0013] A continuous annealing production method of 280MPa grade automotive structural steel, including smelting, hot rolling, cold rolling and continuous annealing processes, the mass percentage of the final chemical composition is: C: 0.145-0.185%, Si: 0.05-0.15, Mn: 0.55 ~0.65, P≤0.025%, S≤0.015%, Als: 0.013~0.023%, N≤0.004%, the rest is Fe; in the smelting process, the end point requirement of converter blowing: C≤0.10%, P<0.015% , S≤0.035%; when tapping reaches 30±5%, add lime with a mass ratio of 0.4% to the ladle for prefabrication of slag, the tapping time is longer than 5-8 minutes, and use slag stopper and slag stopper cone when tapping Carry out front and back slag blocking; refining time: 35 to 65 minutes, refining and adding aluminum magnesium calcium iron and lime for white slag desulfurization operation, the aluminum content in the process is controlled at 250-350ppm, and the refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com