Block copolymer of polyolefine and phosphorus-containing alkene and preparation method thereof

An olefin block and polyolefin technology, applied in the field of block copolymer and its preparation, can solve the problem of less phosphorus-containing block polymer, and achieve the effects of low cost, wide source of raw materials and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

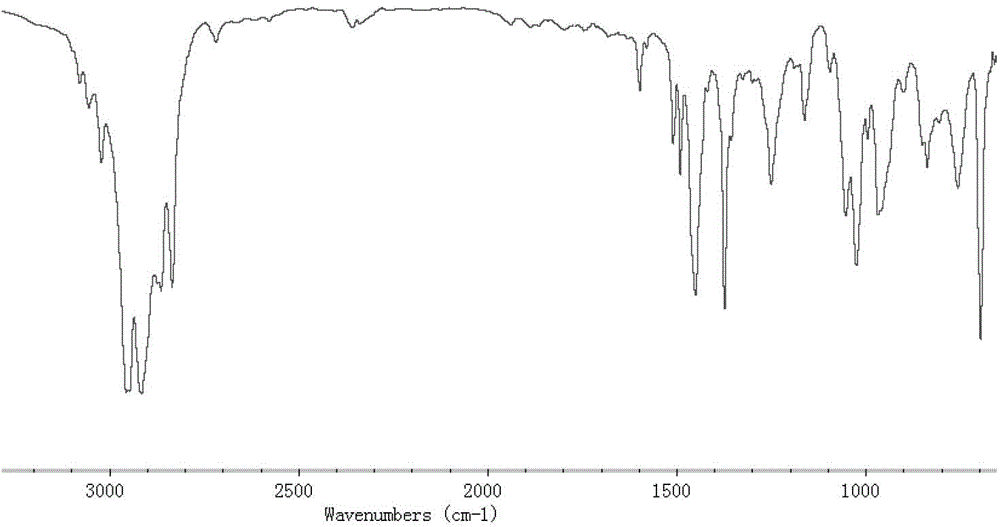

[0061] In a 100ml three-necked bottle, add 0.300g (0.018mmol) Mn=1.7×10 4 After the benzyl chloride-terminated polypropylene was vacuum-dried at 60°C for 4 hours, 20 ml of toluene was added and stirred to fully dissolve the benzyl chloride-terminated polypropylene, and then 20.1 mg (0.203 mmol) of cuprous chloride, 1,1,4,7,10,10-Hexamethyltriethylenetetramine 45ul (0.17mmol), 5ml (24mmol) comonomer DEVBP, fully deoxygenated, reacted at 90°C for 4h under nitrogen protection. The reaction was quenched by bubbling air and the polymer was precipitated with hexane or heptane. The polyolefin / phosphorus-containing olefin block copolymer is obtained by repeatedly adding dichloromethane or trichloromethane and other halogenated hydrocarbons to dissolve, then precipitating and washing the polymer with hexane or heptane to remove unreacted monomers, filtering and drying.

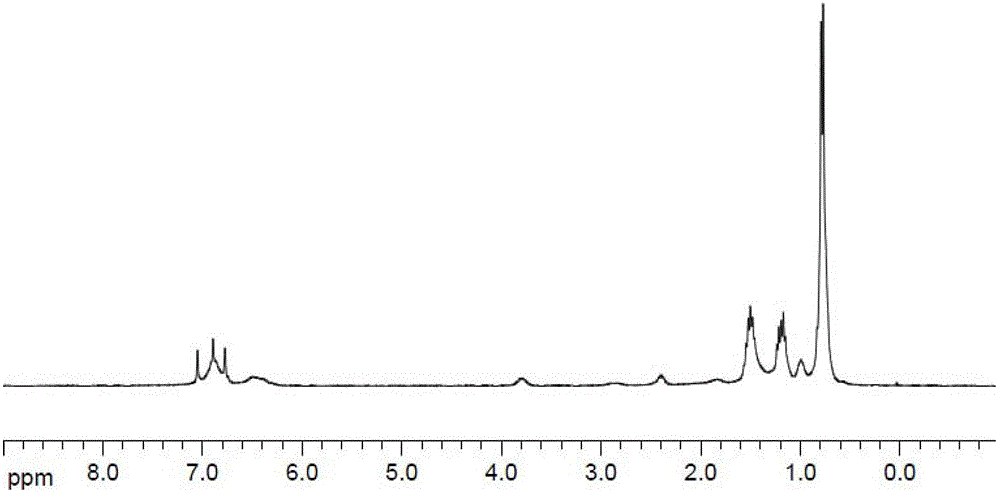

[0062] 1 H-NMR characterization confirmed that the molar content of phosphorus-containing olefin segments in the c...

Embodiment 2

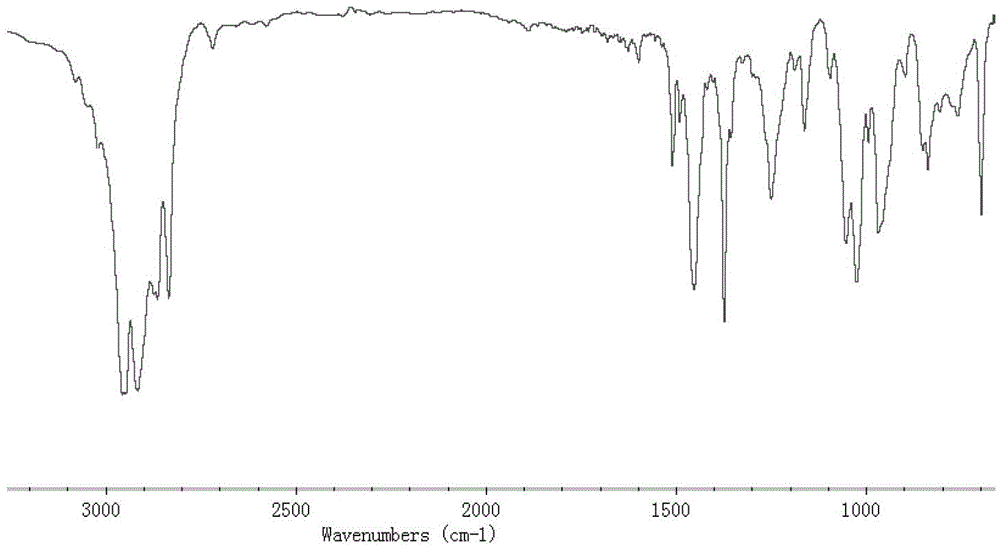

[0066] In a 100ml three-necked bottle, add 0.300g (0.018mmol) Mn=1.7×10 4 After the benzyl chloride-terminated polypropylene was vacuum-dried at 60°C for 4 hours, 20ml of toluene was added and stirred to fully dissolve the benzyl chloride-terminated polypropylene, and then 20.1mg (0.20mmol) of cuprous chloride (0.20mmol) was added successively. 1,1,4,7,10,10-Hexamethyltriethylenetetramine 45ul (0.19mmol), 5ml (24mmol) comonomer DEVBP, fully deoxygenated, reacted at 90°C for 12h under nitrogen protection. The reaction was quenched by bubbling air and the polymer was precipitated with hexane or heptane. The polyolefin / phosphorus-containing olefin block copolymer is obtained by repeatedly adding dichloromethane or trichloromethane and other halogenated hydrocarbons to dissolve, then precipitating and washing the polymer with hexane or heptane to remove unreacted monomers, filtering and drying.

[0067] 1 H-NMR characterization confirmed that the molar content of phosphorus-cont...

Embodiment 3

[0070] In a 100ml three-necked bottle, add 0.300g (0.018mmol) Mn=1.7×10 4 After the benzyl chloride-terminated polypropylene was vacuum-dried at 60°C for 4 hours, 20ml of toluene was added and stirred to fully dissolve the benzyl chloride-terminated polypropylene, and then 20.1mg (0.20mmol) of cuprous chloride (0.20mmol) was added successively. 1,1,4,7,10,10-Hexamethyltriethylenetetramine 45ul (0.19mmol), 5ml (24mmol) comonomer DEVBP, fully deoxygenated, reacted at 90°C for 18h under nitrogen protection. The reaction was quenched by bubbling air and the polymer was precipitated with hexane or heptane. The polyolefin / phosphorus-containing olefin block copolymer is obtained by repeatedly adding dichloromethane or trichloromethane and other halogenated hydrocarbons to dissolve, then precipitating and washing the polymer with hexane or heptane to remove unreacted monomers, filtering and drying.

[0071] 1 H-NMR characterization confirmed that the molar content of phosphorus-cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com