A horizontal support cover manhole

A horizontal and capping technology, applied to underwater structures, buildings, infrastructure engineering, etc., can solve the problems of unfavorable protection of manhole sealing surface, sealing surface damage, etc., achieve good application prospects, reduce work intensity and effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

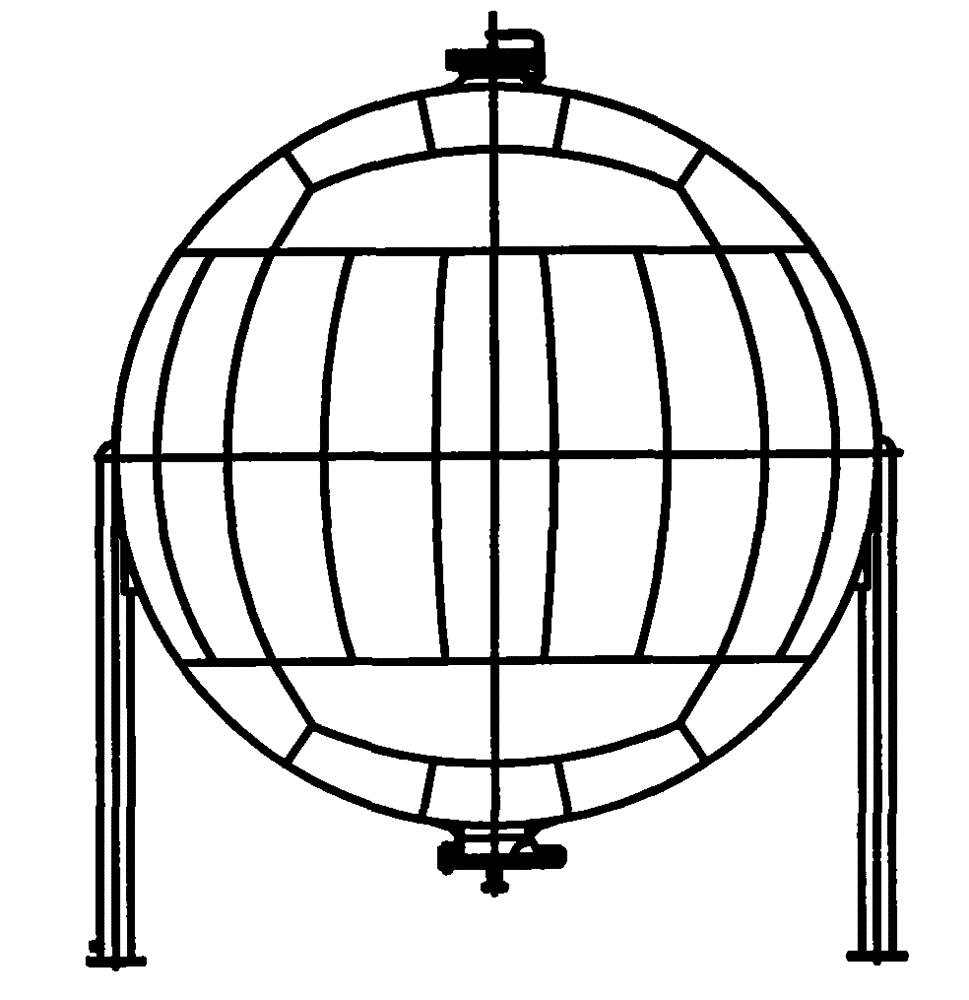

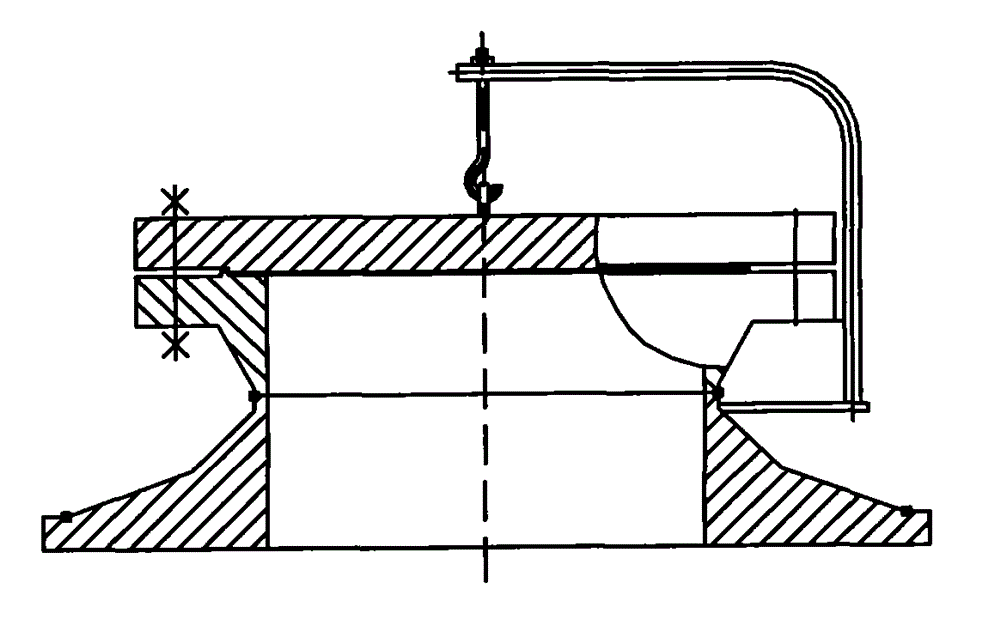

[0056] Such as Pic 4-1 and 4-2 Shown: a horizontal support cover manhole, a manhole barrel section and a manhole cover 10, the manhole barrel section includes a manhole flange and a manhole flange 11.

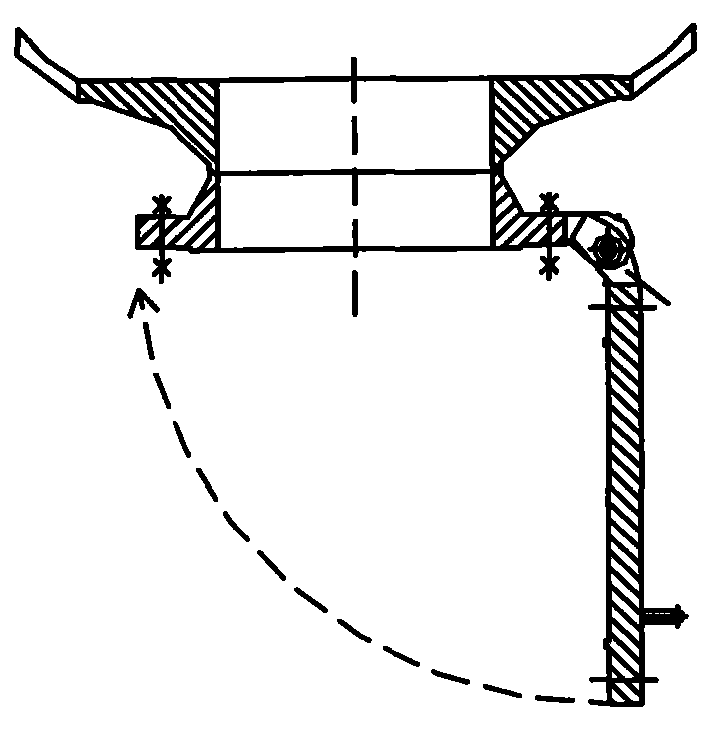

[0057] Described manhole cover 10 is provided with joist 7, and described joist 7 is " L " shape, and the horizontal leg of joist 7 is arranged on the following of manhole cover 10 and supports manhole cover 10, and the outer wall of manhole cylinder section A sleeve-type support system is provided, and the vertical limbs of the joist 7 are vertically arranged on the side of the manhole through the sleeve-type support system, and can drive the manhole cover 10 to rotate in the horizontal plane with the vertical limbs of the joist 7 as the central axis ;

[0058] The sleeve type support system includes: an upper support plate 3, a lower support plate 5, a sleeve 4, a rib plate 6 and double nuts 2; the rib plate 6 is a vertical vertical plate, and a vertical vertical sleeve is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com