Spring assembly machine for spring lock

A technology for assembly machines and pin locks, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult export of spring holes, low work efficiency, and spring drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

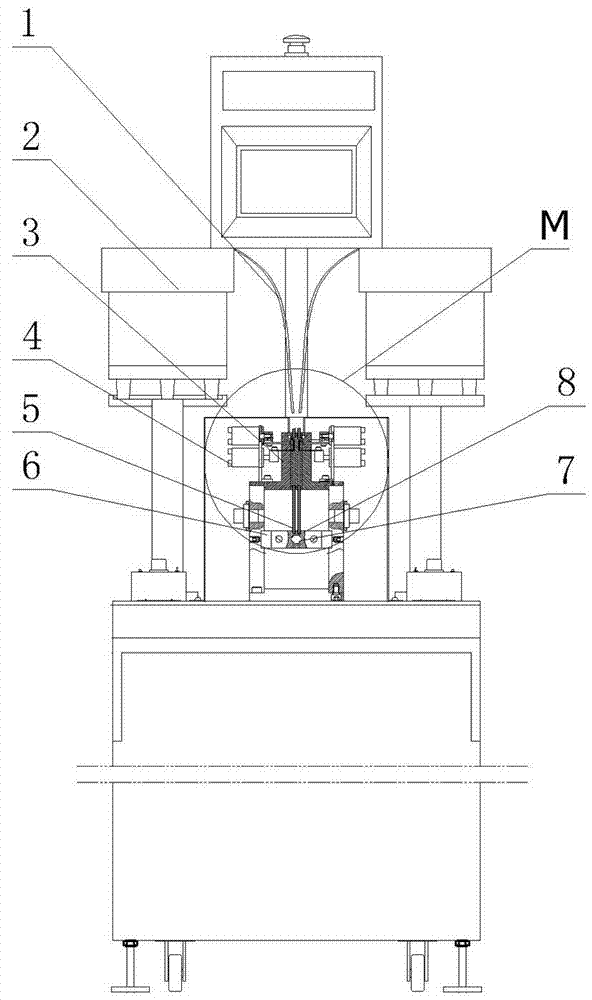

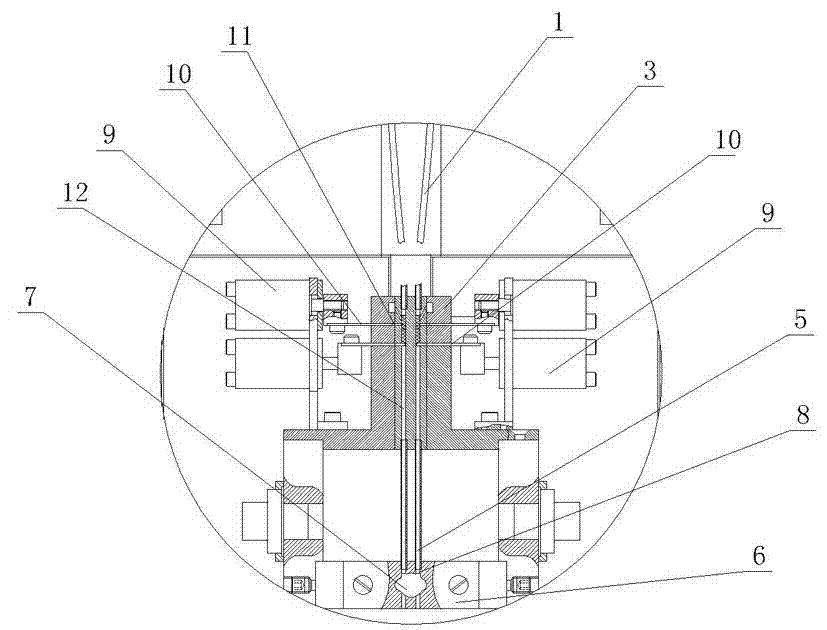

[0016] Embodiment one: refer to Figure 1~Figure 3 , this pin lock spring assembly machine includes a spring feeder 2, a feed pipe 1, a mold base 6, a feed head 3 and a material control device, and the feed head 3 has a number of longitudinal passages 12 arranged in a line for springs to pass through, The quantity of the longitudinal channel 12 corresponds to the quantity of pinholes on the tumbler lock cylinder. The material control device is installed on the side of the feeding head 3. The material control device includes a first material control device and a second material control device. The first material control device is arranged above the second material control device, and both the first material control device and the second material control device include a transverse through hole 11, a support rod 10 and a first cylinder 9, and the transverse through hole 11 communicates with the longitudinal channel 12 , and the support rod 10 is installed on the push rod of the ...

Embodiment 2

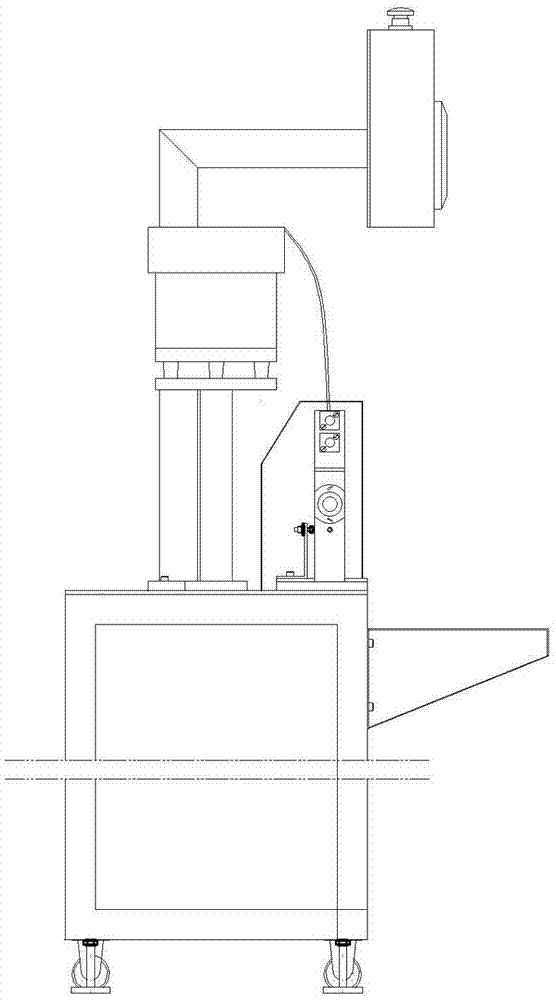

[0017] Embodiment two: refer to Figure 4~Figure 6 , in this embodiment, wherein the structure of the mold base is different from that of Embodiment 1, the difference is that the station for placing the lock core is a lock core mold pad 16, and a slidable slide plate 14 is installed on the mold base 6 , the second air cylinder 15 is installed on the slide plate 14 , and the die pad 16 is connected with the second air cylinder 15 . Other structures are the same as in Embodiment 1. The structure of the lock cylinder in this embodiment is different from that in Embodiment 1. In the lock cylinder of Embodiment 1, the pin hole is arranged on the side of the lock core, and the pin hole and the key hole on the lock core are perpendicular to each other. For the lock core in this embodiment, the pin hole is arranged on the end surface of the lock core, and the pin hole and the key hole are parallel to each other, therefore, the lock core needs to be placed upright. Therefore, when as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com