Automatic overturn supporting device for crank shaft blank

A technology of automatic inversion and support device, which is applied in operating devices, forging/pressing/hammer devices, metal processing equipment, etc., can solve the problems reported in literature about automatic inversion and support device for crankshaft blanks, increase the complexity of the manipulator mechanism, and prolong the production cycle. and other problems, to achieve the effect of shortening the production cycle, improving the labor productivity of the enterprise, and reducing the complexity of the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

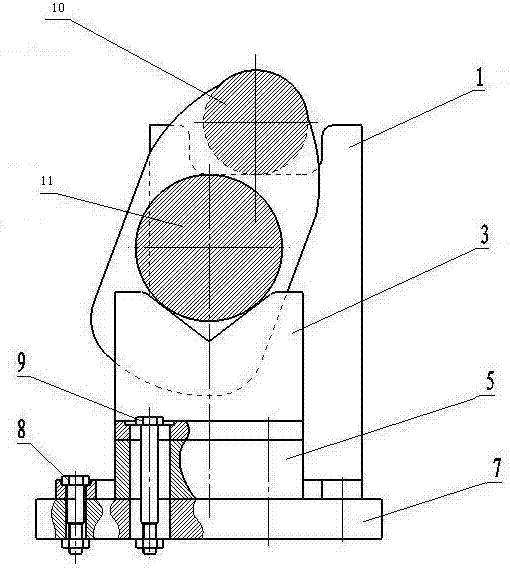

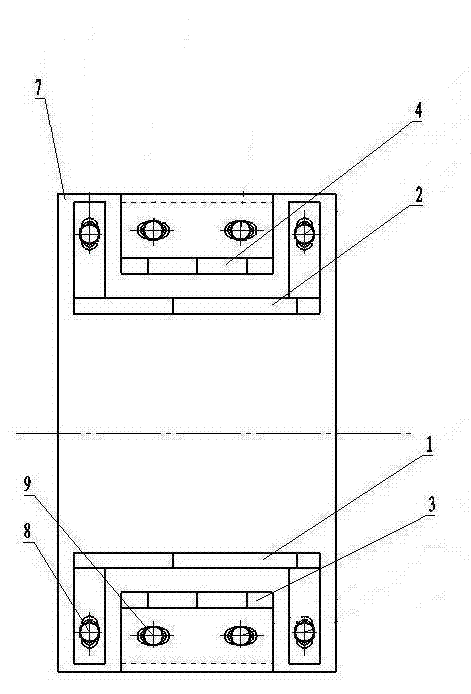

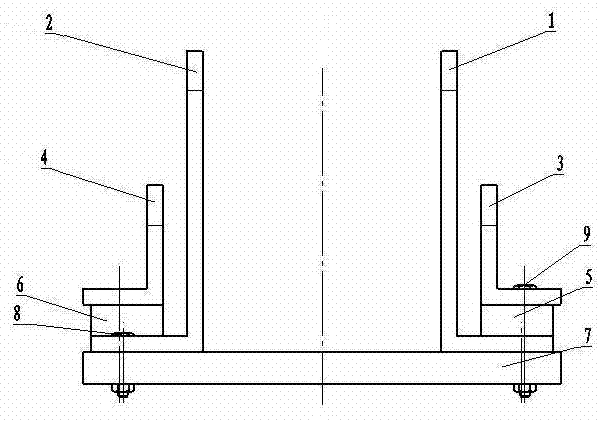

[0016] From figure 1 , figure 2 , image 3 It can be seen from the figure that a crankshaft blank automatic flip supporting device is provided with a base 7 for installing and supporting the whole device. Two connecting rod support plates 1, 2 and two main shaft support plates 3, 4 are symmetrically installed on the base 7, and the bottoms of the connecting rod support plates 1, 2 and the main shaft support plates 3, 4 are vertically provided with legs, And are respectively fixed on the base 7 by bolt 8 and bolt 9. The main shaft supporting plates 3, 4 are lower than the connecting rod supporting plates 1, 2, and the supporting centers of the main shaft supporting plates 3, 4 deviate from the supporting centers of the connecting rod supporting plates 1, 2. The connecting rod support plates 1 and 2 are used to accept the second and fifth connecting rods 10 of the six-cylinder crankshaft blank, and the main shaft support plates 3 and 4 are used to accept the second and sixth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com