Nano silicon dioxide stirring modification method and device thereof

A nano-silica and modification technology, which is applied in the field of nano-silica stirring and modification methods and devices, can solve the problems of large consumption of modified additives, uneven modification and mixing, uneconomical and the like, and achieve equipment processing costs. And the effect of low operating cost, large-scale industrialization, and low technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

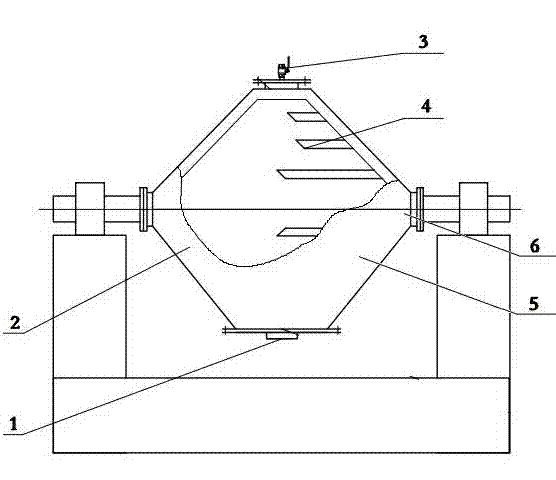

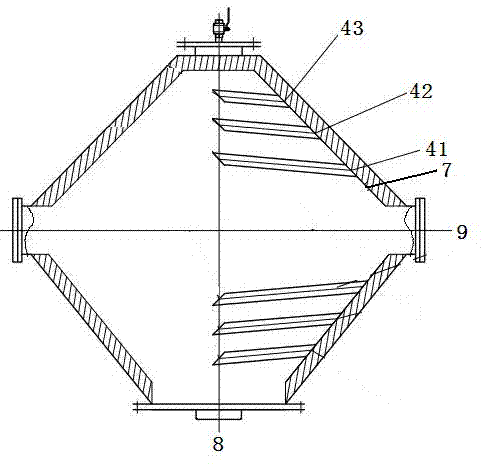

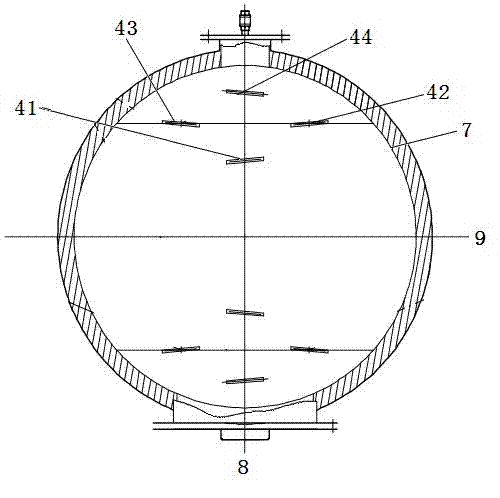

[0019] Make the kettle body 2, make the two ends of the kettle body 2 into cones 5 with a conical structure, install the manhole 1 on the lower part of the kettle body 2, install the feeding port and the discharge port 3 on the upper part of the kettle body 2, and install the inner wall 7 on the kettle body. The diversion baffle 4 is installed; the diversion baffle 4 is installed on the still inner wall 7 of the cone 5 at one end of the kettle body 2, eight pieces are installed in total, and the vertebral body 5 is divided into two parts with the horizontal center line 9 as the boundary , Four guide baffles 4 are respectively installed in the kettle inner wall 7 of every part of the cone 5 .

[0020] The installation method of the flow guide baffle 4 is to fix one end of the flow guide baffle 4 on the inner wall 7 of the kettle, and the position distribution of the fixed points is: install the flow guide baffle A41 at a quarter of the distance from the cone bottom 6, When inst...

Embodiment 2

[0024] The kettle body 2 is also made, and the two ends of the kettle body 2 are made into a cone 5 with a conical structure. The diversion baffle 4 is installed on the top; the diversion baffle 4 is installed on the inner wall 7 of the still body 2 one end cone 5 of the kettle body, eight pieces are installed altogether, and the vertebral body 5 is divided into two with the horizontal centerline 9 as the boundary. Partly, four diversion baffles 4 are respectively installed on the kettle inner wall 7 of each part of the cone 5 .

[0025] The installation method of the flow guide baffle 4 is to fix one end of the flow guide baffle 4 on the inner wall 7 of the kettle, and the position distribution of the fixed points is: install the flow guide baffle A41 at a quarter of the distance from the cone bottom 6, When installing, the width of the diversion baffle A41 is 120mm, the thickness is 14mm, and the plane and the horizontal centerline 9 form an angle of 5°; at one-half of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com