Plant cultivating substrate as well as preparation method and application of same

A plant cultivation and matrix technology, applied in application, cultivation, agriculture, etc., can solve the problems of fertilizer loss, high construction cost, inconvenient application and construction, etc., and achieve the effects of good survival and growth, low cost, and low later management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

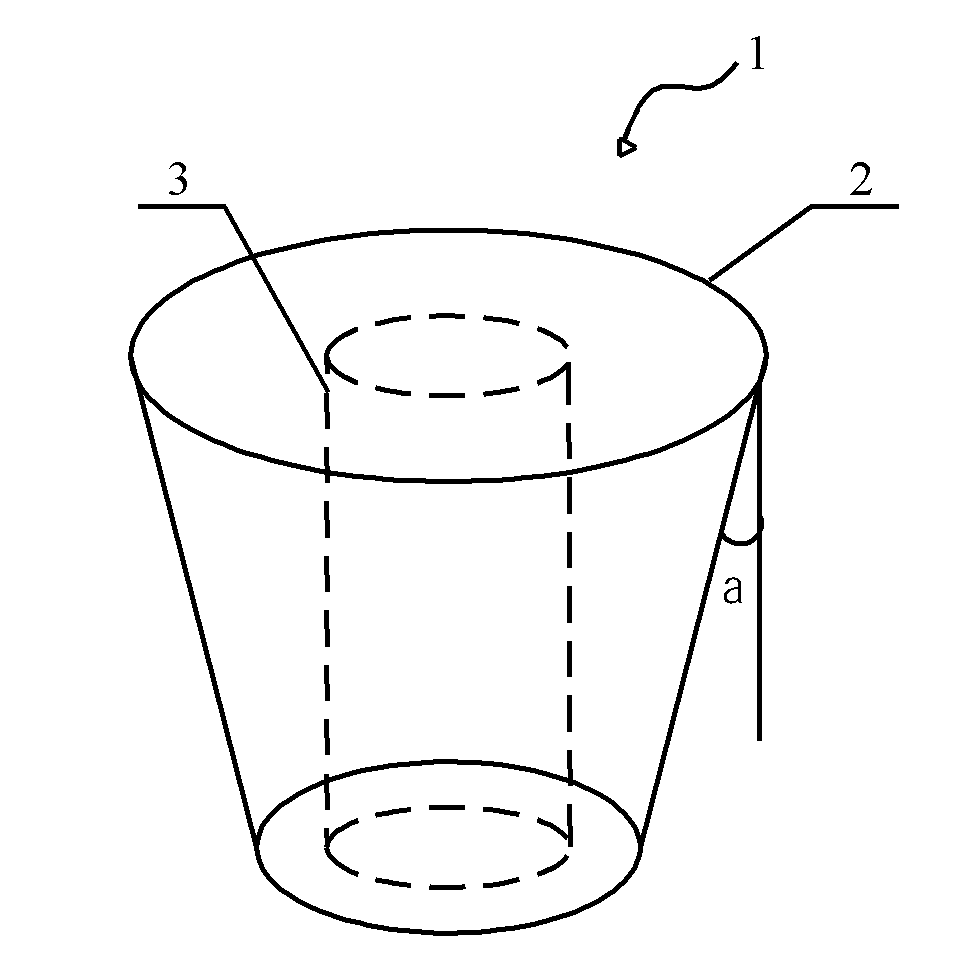

[0045] Fully mix 1000g of soil (sieved) on the campus of Beijing University of Chemical Technology with 0.10g of solid polyaspartic acid water-absorbing resin powder, then add 100ml of water, stir and mix evenly, granulate the soil, put it into a mold, and mold it. made as figure 1 The outer diameter of the upper bottom shown is 10 cm, the outer diameter of the lower bottom is 5 cm, and the height is 5 cm. The axis is provided with a truncated cone 2 with a diameter of 3 cm and a cylindrical hole 3 that runs through the longitudinal direction. Under room temperature, it is naturally dried. After 3 days, the plant cultivation substrate 1 was prepared.

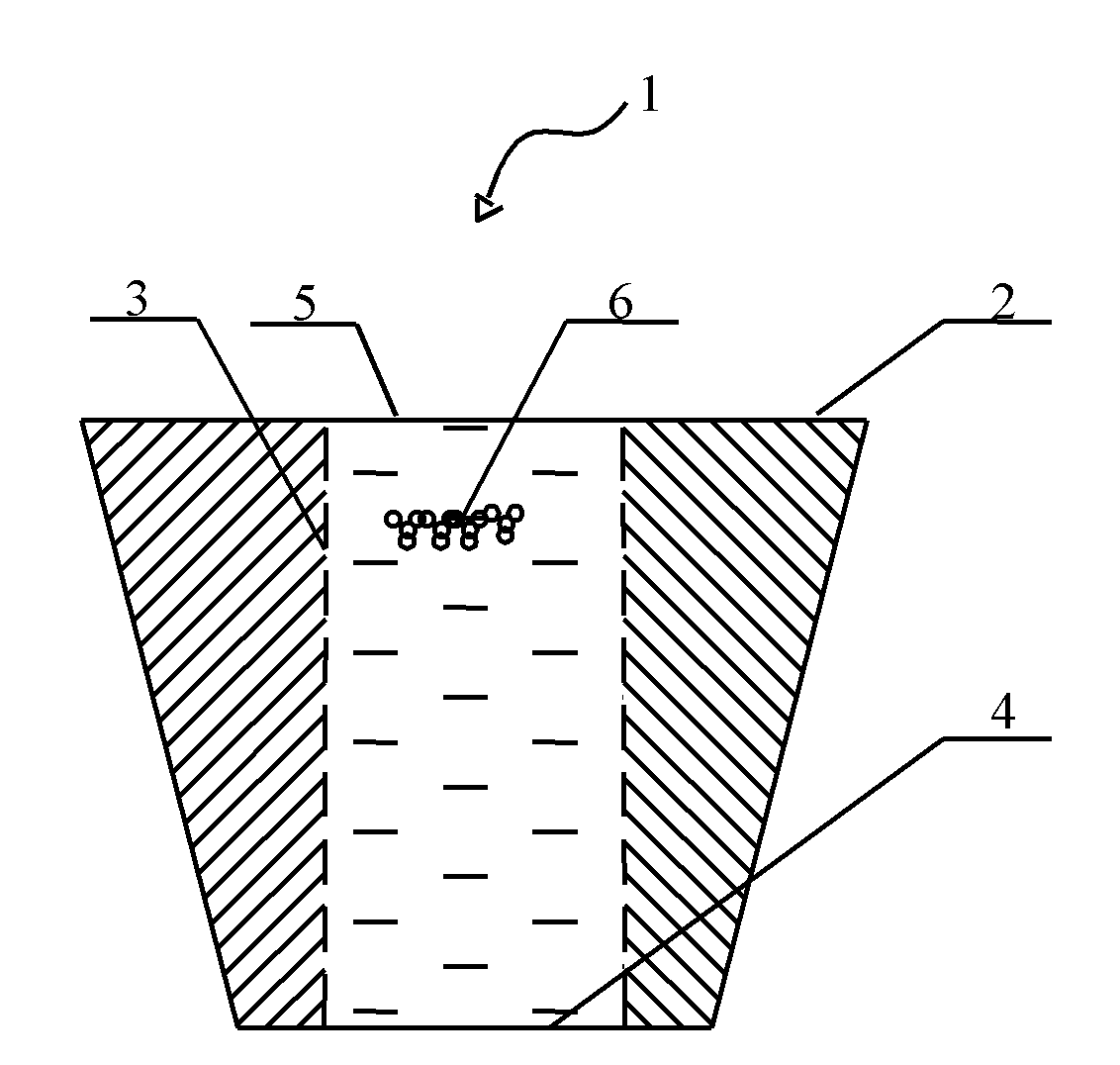

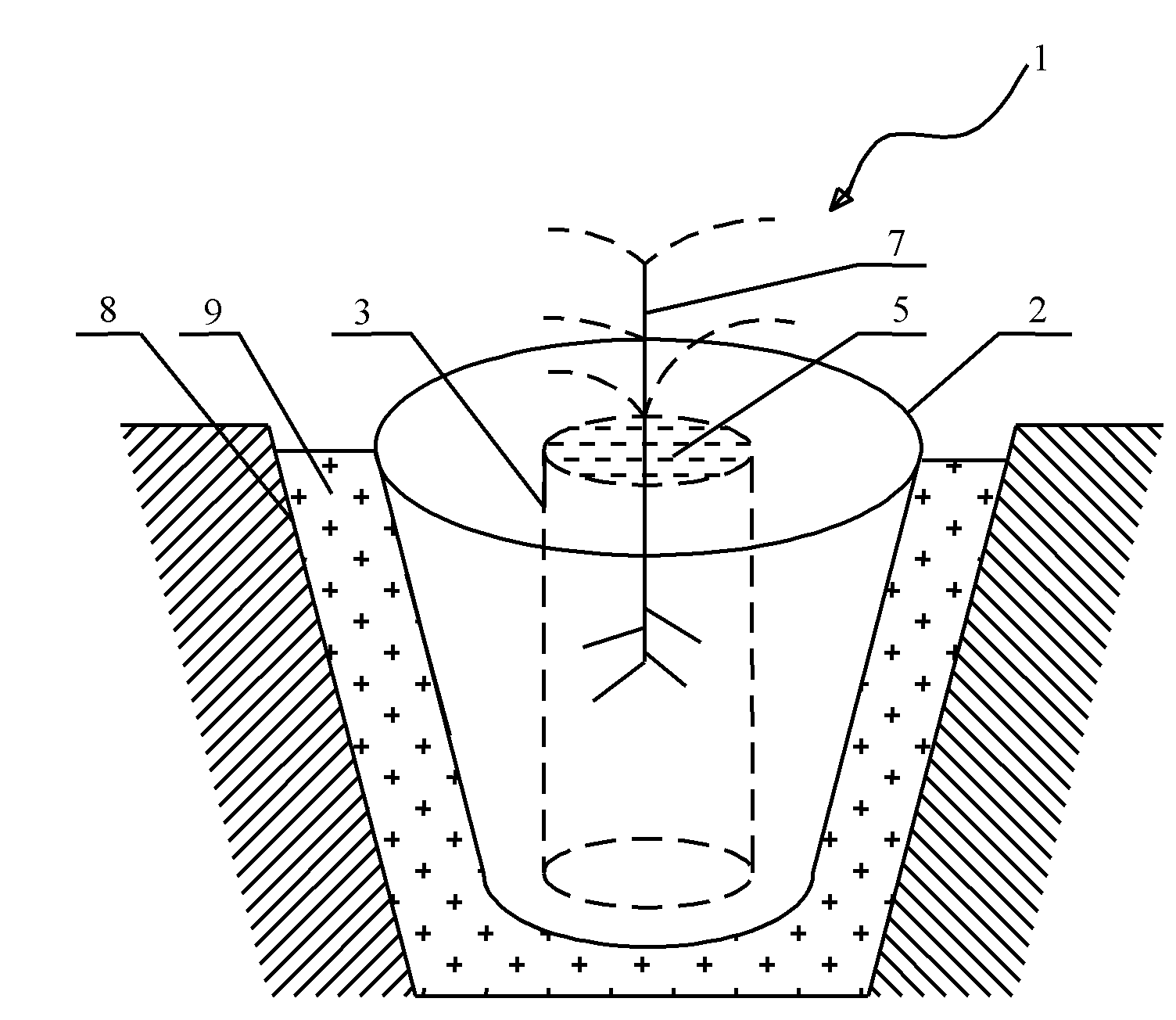

[0046] figure 2 A cross-sectional view of a stage during use of the above-mentioned plant growth substrate is shown. Such as figure 2 As shown, when sowing, first use waste newspaper 4 and starch paste to wrap around the plant cultivation substrate and the lower bottom surface, then 500g humus, 2.5g polyaspartic acid fertil...

Embodiment 2

[0049] Fully mix 2000g of the soil (sieved) on the campus of Beijing University of Chemical Technology with 20.00g of solid polyaspartic acid water-absorbing resin powder, then add 400ml of water, stir and mix evenly, put it into a mold, and mold it to form an outer surface of the upper bottom surface. 20 cm in diameter, 10 cm in outer diameter of the bottom surface, 20 cm in height, and a truncated cone with a diameter of 10 cm and a cylindrical hole passing through the longitudinal direction at the center of the axis. A plant growth substrate is prepared.

[0050] When sowing, first use waste newspaper and starch paste to wrap the surrounding and lower bottom of the plant cultivation substrate, then fully mix 1000g of humus soil, 10.0g of polyaspartic acid fertilizer powder, and add 1.0g of polyaspartic acid A colloidal solution made of water-absorbent resin, stirred and mixed evenly to make a moist plant culture substrate, and added into the cylindrical longitudinal through h...

Embodiment 3

[0054] Fully mix 2000g of the soil (sieved) on the campus of Beijing University of Chemical Technology with 60.00g of solid polyaspartic acid water-absorbing resin powder, then add 600ml of water, stir and mix evenly, put it into a mold, and mold it to form a product such as Figure 4 The outer diameter of the circumscribed circle on the upper bottom surface shown is 20cm, the outer diameter of the circumscribed circle on the lower bottom surface is 15cm, and the height is 30cm. The axis is provided with a truncated triangular pyramid 2 with a diameter of 8cm and a cylindrical hole 3 extending vertically. , put the truncated cone into an oven, and dry it at 60° C. for 18 hours to obtain the plant cultivation substrate 1 .

[0055] Use waste newspaper and starch paste to wrap the surrounding and lower bottom of the plant cultivation substrate, then mix 1000g of humus soil, 10.0g of polyaspartic acid fertilizer powder, and 1.0g of polyaspartic acid water-absorbing resin powder an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com